Entirety and part combined identification method of ballastless track damage

An identification method and ballastless track technology, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as unsuitable ballastless track damage detection, and achieve high detection accuracy and easy test operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

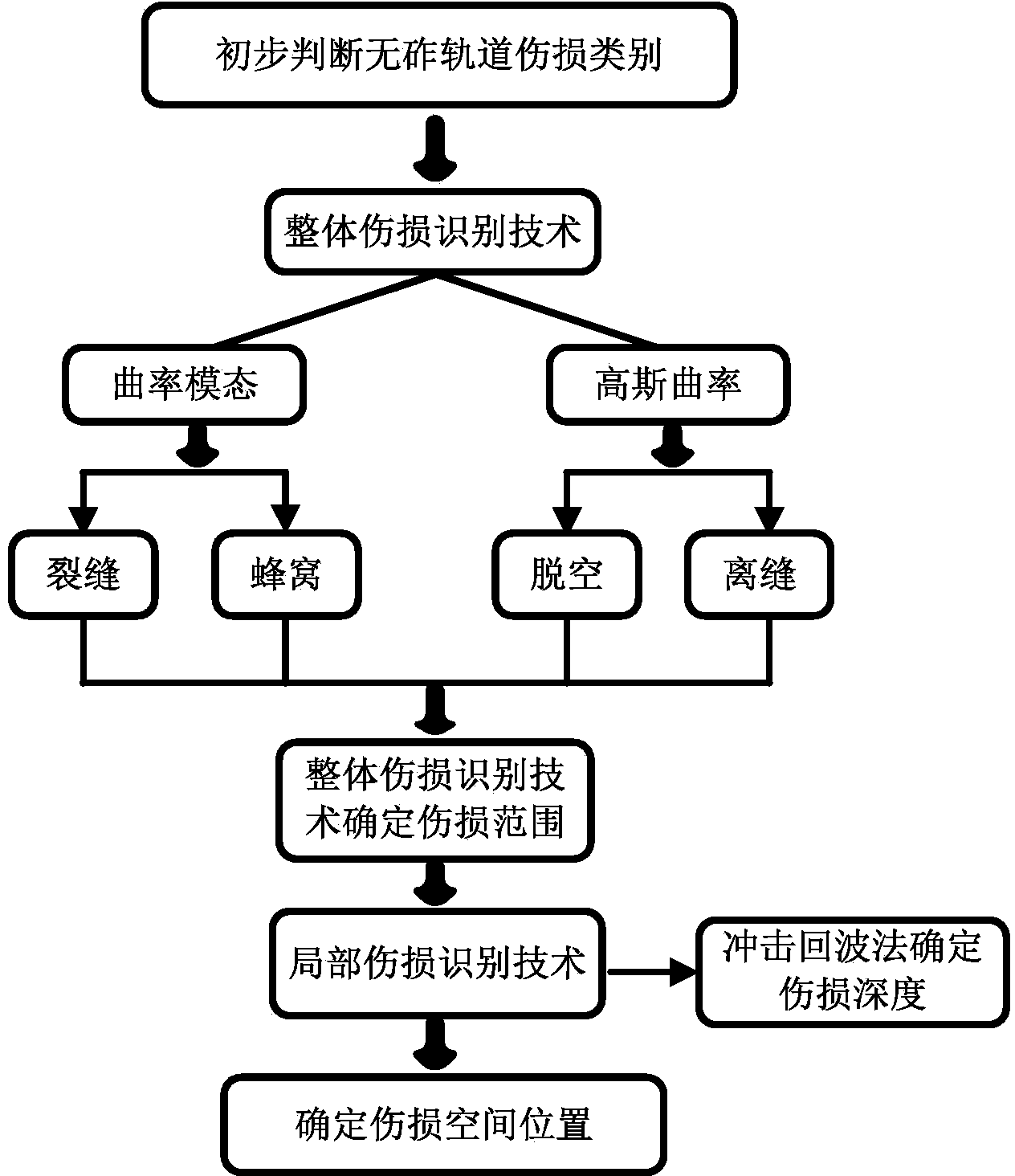

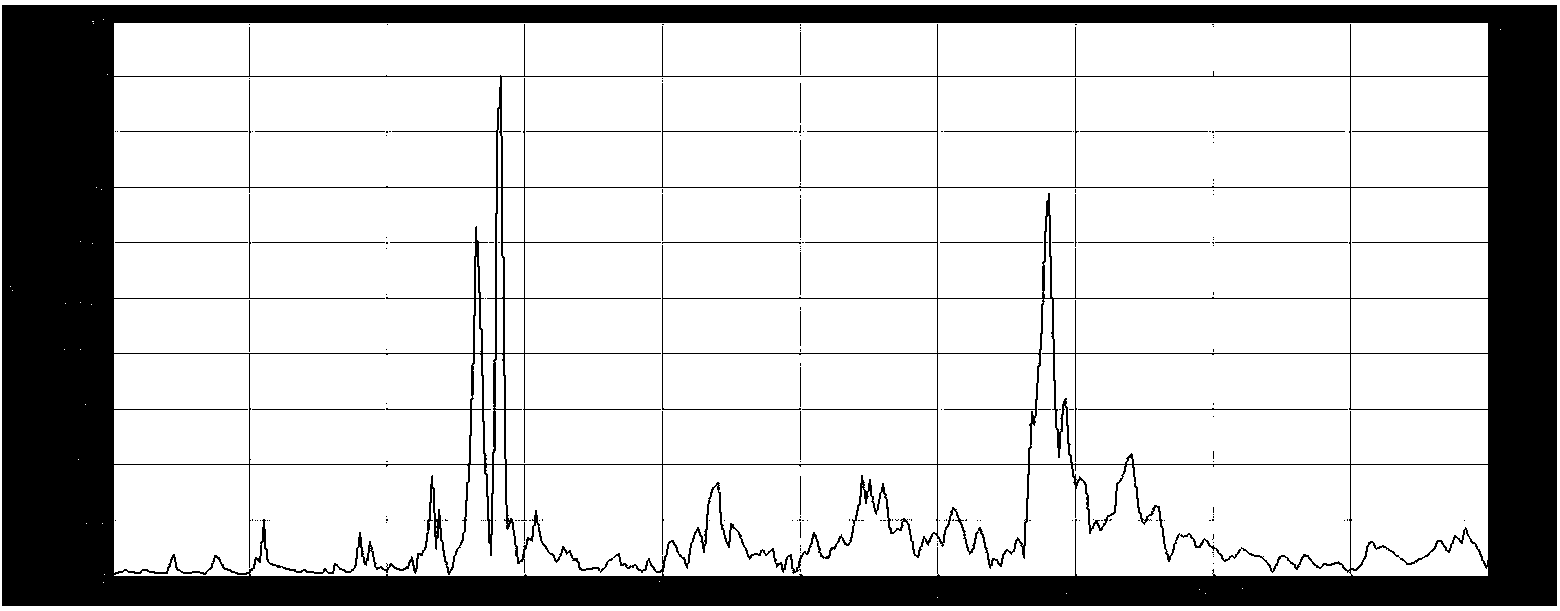

[0018] figure 1 The working process of the method of the present invention is expressed. First, the overall damage identification method-curvature modal method is used to determine the area where the damage occurs; secondly, the local damage detection technology-shock echo method is used to further determine the damage depth in the damaged area; Accurately locate the spatial position of the damage, that is: 1) Arrange acceleration sensors at a certain distance on the track slab, use multi-point excitation and multi-point acquisition to collect the surface acceleration of the track slab, and then perform modal analysis to identify the rough area of the damage ; 2) After 1) is completed, the shock echo technology is used to identify the depth of the damage, and finally locate the spatial position of the damage accurately.

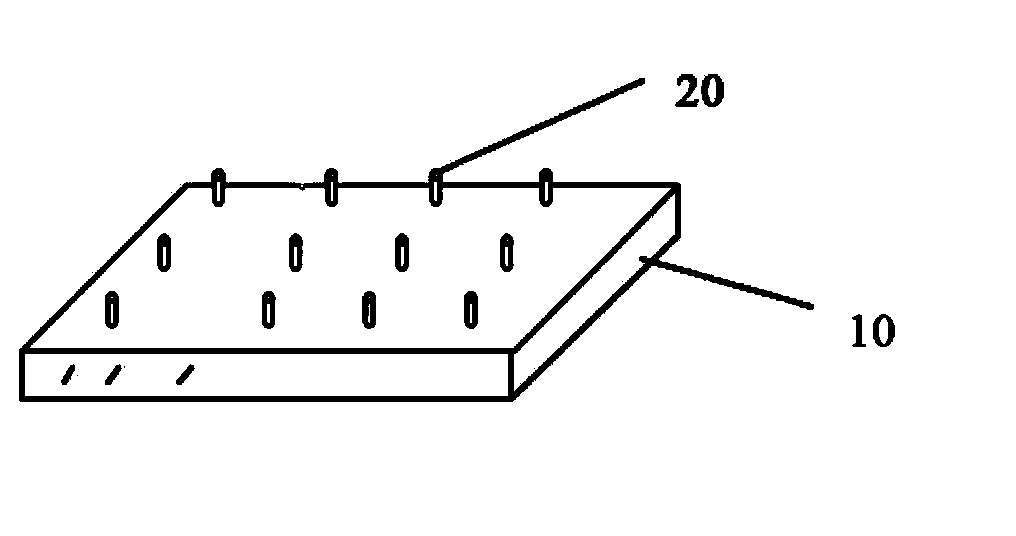

[0019] In order to verify the accuracy of Gaussian curvature in identifying ballastless track damage, a slab ballastless track model was made indoors, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com