Battery module and method for connecting battery modules in series

A battery module and battery technology, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of reduced battery module life, reduced battery module life, inconsistent aging speed of battery module 1 and battery module 2, etc., to avoid The effect of inconsistent discharge current and consistent aging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

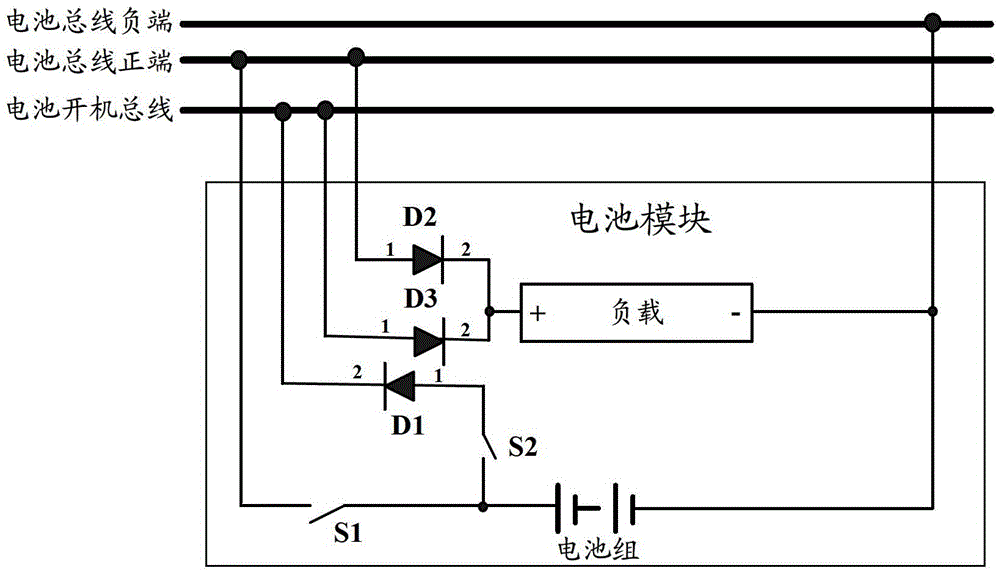

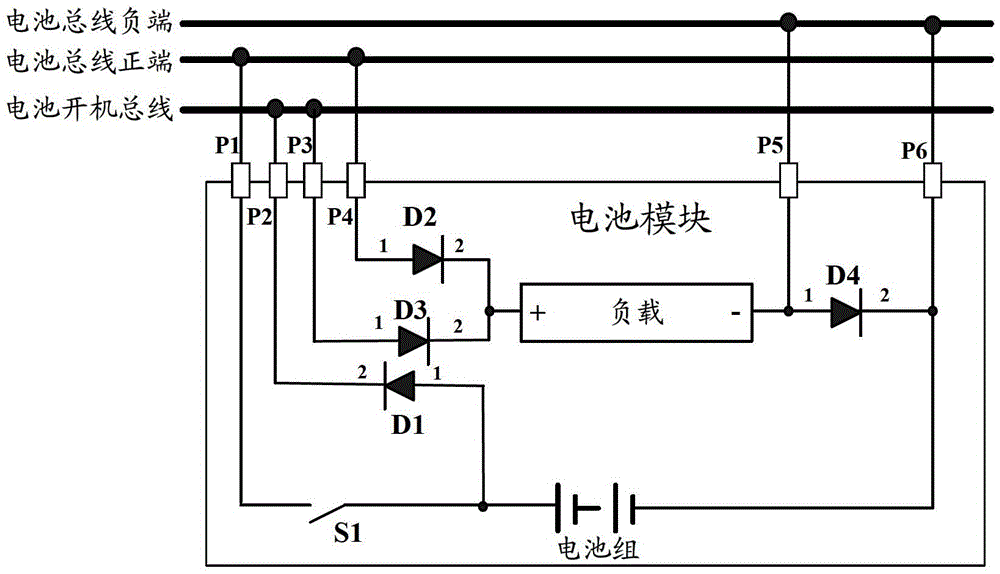

[0045] Such as image 3 As shown, it is a schematic structural diagram of the battery module in Embodiment 1 of the present invention. The battery module is connected to the external battery bus positive terminal, the battery bus negative terminal and the battery power-on bus to provide power for the external module and its own load, including : the first diode D1, the second diode D2, the third diode D3, the fourth diode D4, the first switch S1, the load and the battery pack, and, for connecting to the positive terminal of the battery bus The first interface P1 and the fourth interface P4, the second interface P2 and the third interface P3 for connecting to the battery power-on bus, the fifth interface P5 and the sixth interface P6 for connecting to the negative end of the battery bus, wherein:

[0046] The first switch S1 is used to control the battery module to access and withdraw from the positive terminal of the battery bus;

[0047] The first diode D1 is used to enable ...

Embodiment 2

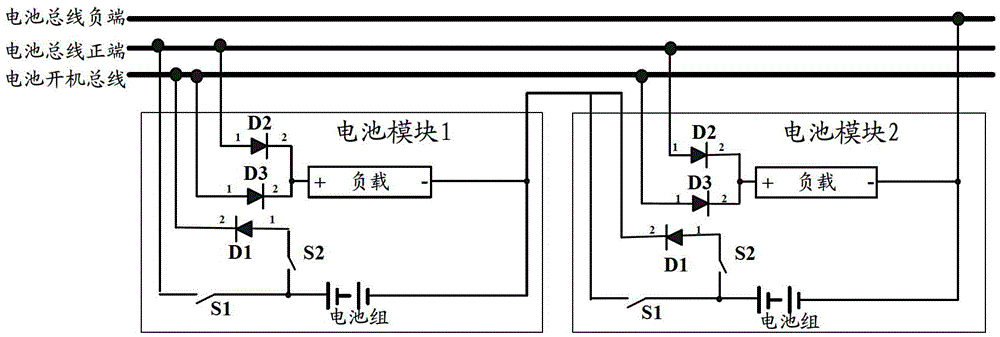

[0073] Such as Figure 6 As shown, it is a schematic structural diagram of the power supply device provided by Embodiment 2 of the present invention, Figure 6 The power supply device in the battery is composed of two battery modules (the first battery module and the second battery module). The load of the included battery module provides power supply, and the first battery module and the second battery module are as in the first embodiment image 3 the battery module shown;

[0074] exist Figure 6 middle, D 11 、D 12 、D 13 and D 14 respectively represent the first to fourth diodes of the first battery module;

[0075] P 11 ,P 12 ,P 13 ,P 14 ,P 15 and P 16 respectively represent the first to sixth interfaces of the first battery module;

[0076] S 11 representing the first switch of the first battery module;

[0077] L 1 Represents the load of the first battery module;

[0078] B 1 a battery pack representing the first battery module;

[0079] D. 21 、D 22...

Embodiment 3

[0109] In the case of N battery modules connected in series, due to the diode D of the Nth battery module N4 is connected to the negative terminal of the battery bus and the load L of the Nth battery module N The wire at the negative end of the short circuit has no effect on the entire circuit, but at this time, even if the Nth battery module does not have a diode D N4 , the Nth battery module still draws power from the voltage of the battery packs of N battery modules connected in series. Therefore, in Embodiment 3 of the present invention, another power supply device is provided:

[0110] The power supply device is connected to the external battery bus positive terminal, battery bus negative terminal and battery power-on bus to provide power for external modules and their own loads, including an existing battery module and N-1 battery modules as described in Embodiment 1 The existing battery module includes all the devices in the battery module described in Embodiment 1 exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com