Bus capacitor discharge method, system and device for power device

A technology for power devices and bus capacitors, which is applied to output power conversion devices, control systems, motors, etc., can solve problems such as hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0209] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

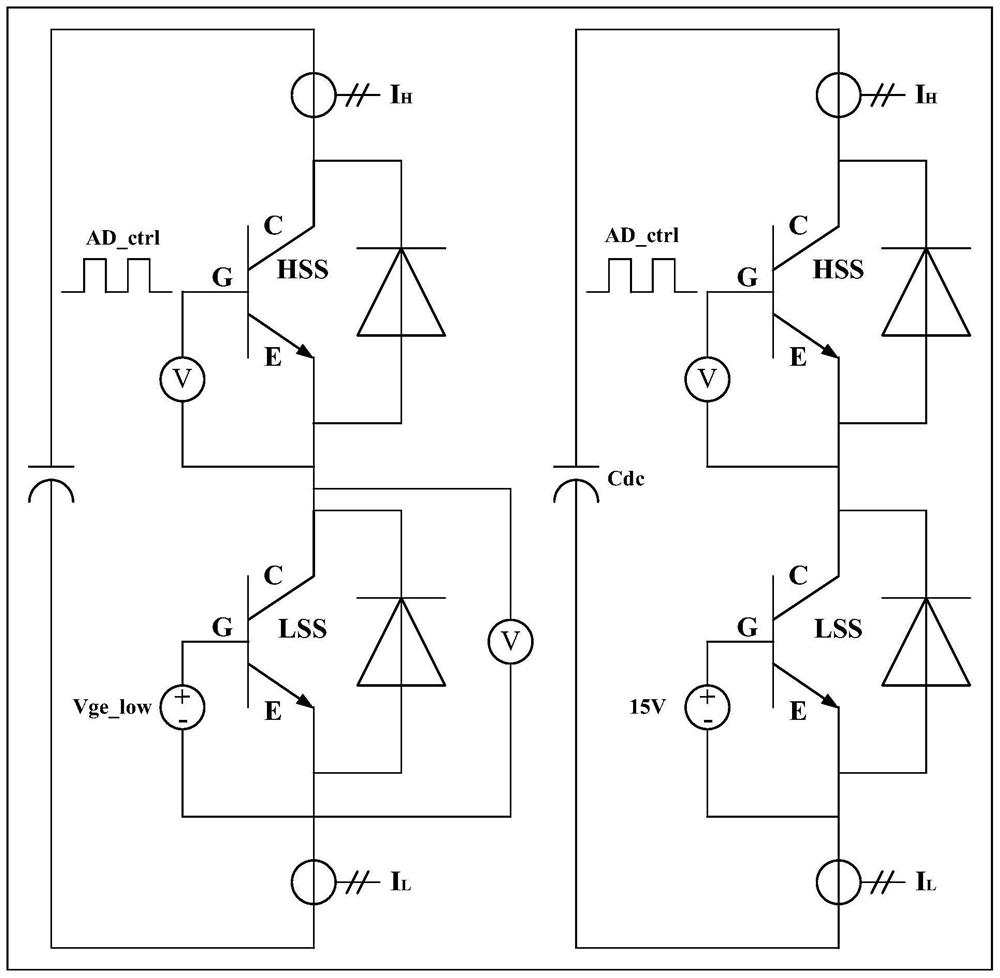

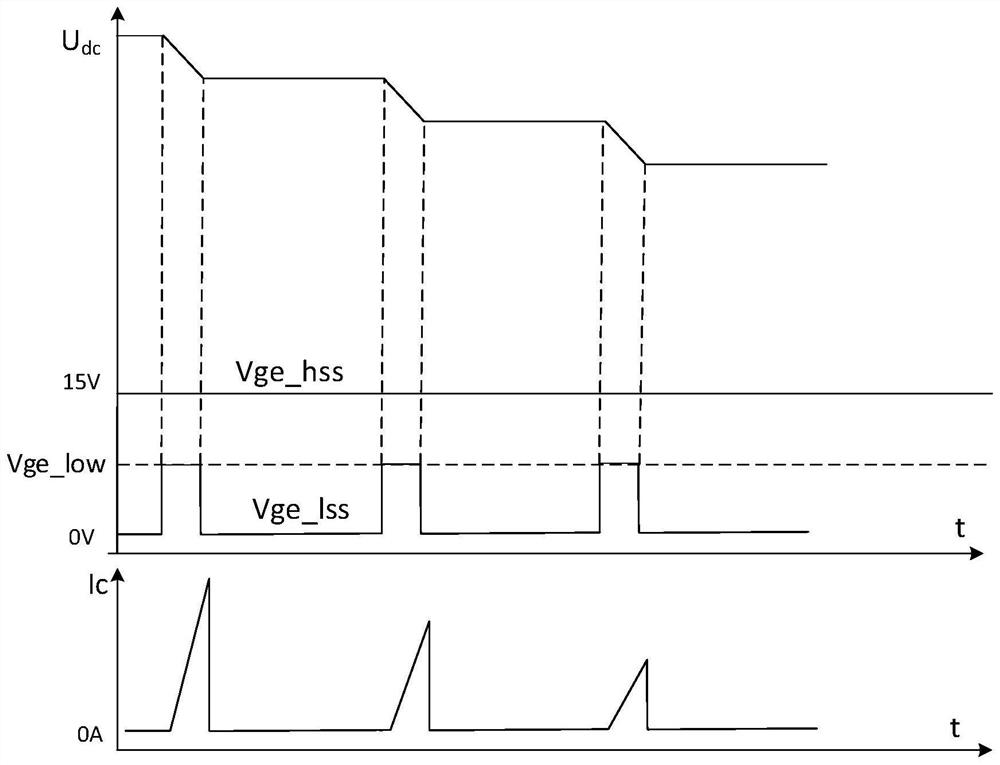

[0210] The active discharge method of the DC bus capacitor in the current power device mainly includes using the discharge resistor or the motor winding to consume the electric energy in the capacitor. This method needs to set up an additional circuit structure and the motor may produce unexpected motor when the discharge is out of control. torque. Based on this, the present invention provides a method to discharge the DC bus capacitor by using the direct connection of the half bridge circuit in the power device to consume electric energy. To effectively control the discharge process.

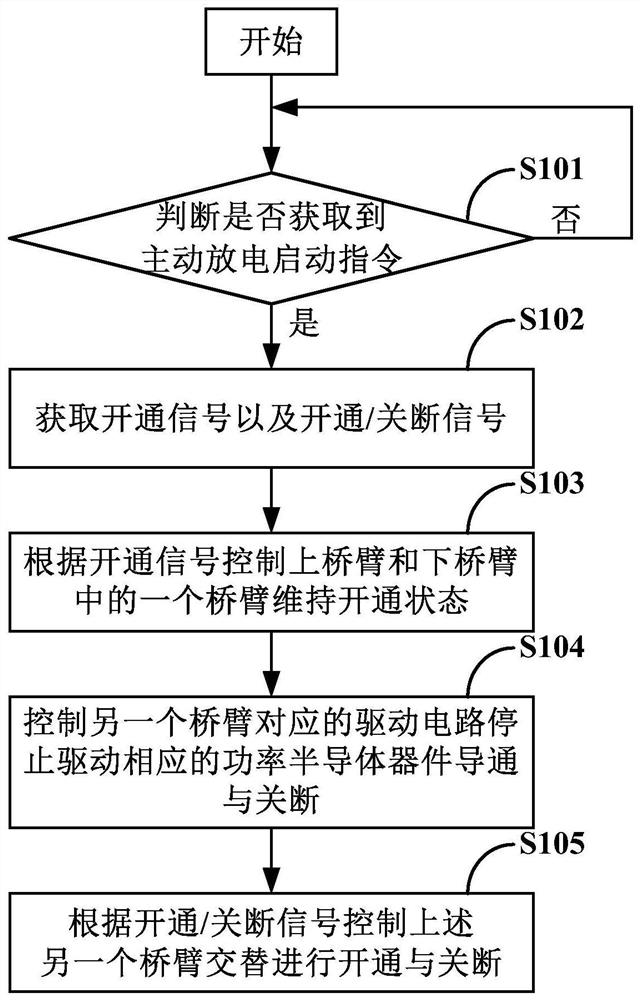

[0211] The specific process of discharging the DC bus c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com