Depalletizing system and removal unit

A technology for extracting units and unstacking, which is applied in the directions of transportation and packaging, unstacking of objects, stacking of objects, etc., can solve problems such as use, deformation, and insufficient stability of product layers, and achieve personnel cost reduction, cost and The effect of the minimization of the required construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

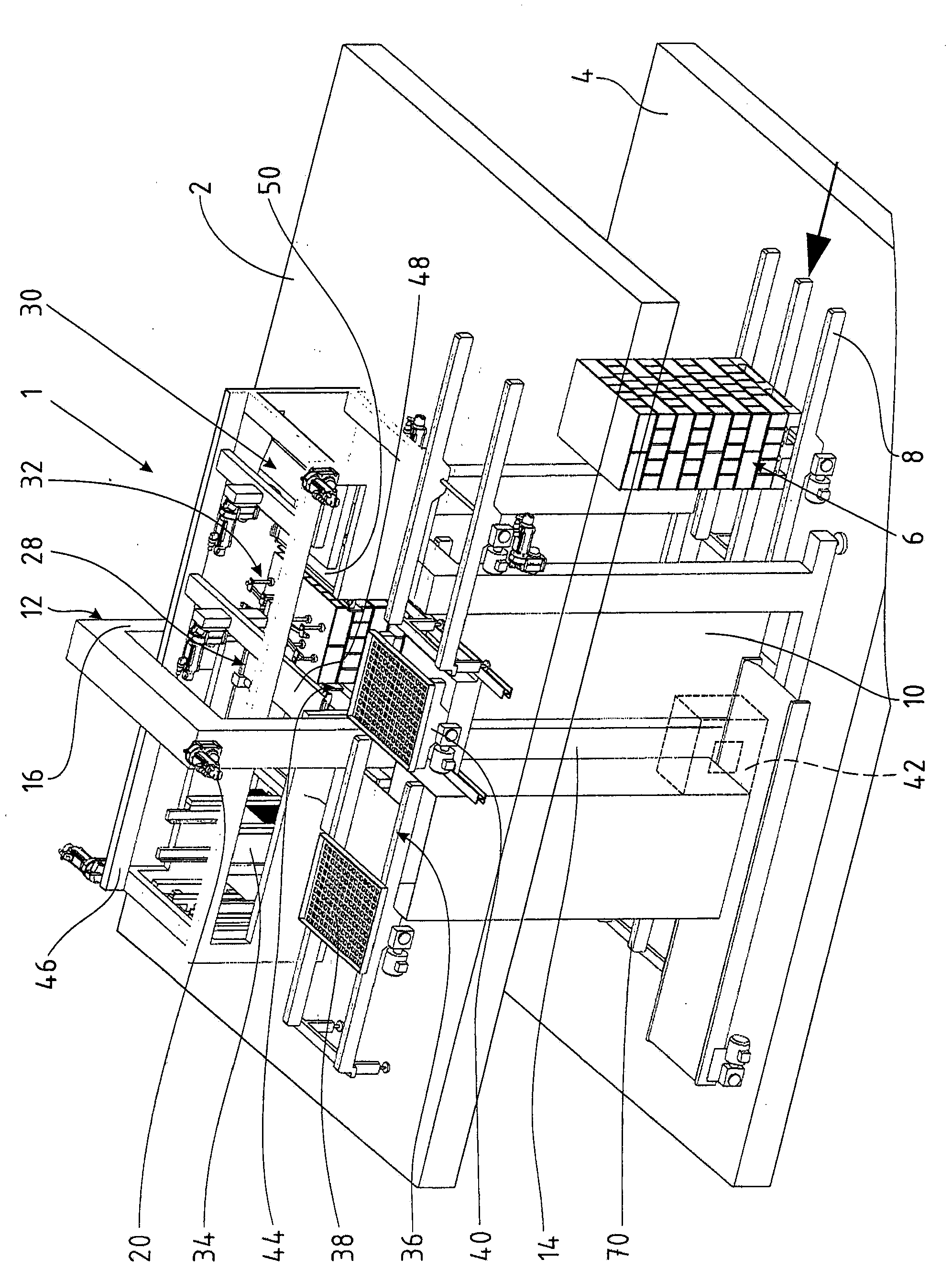

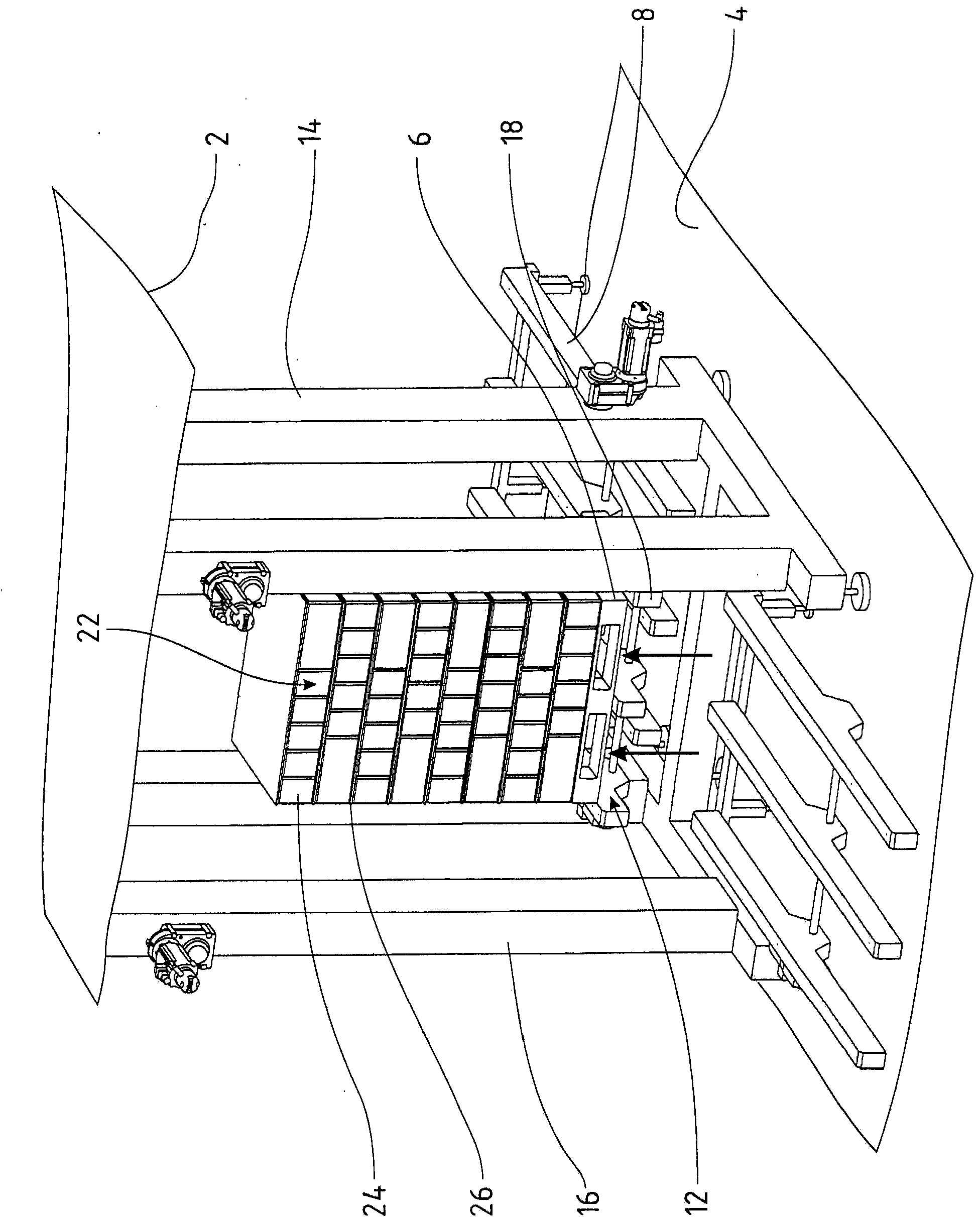

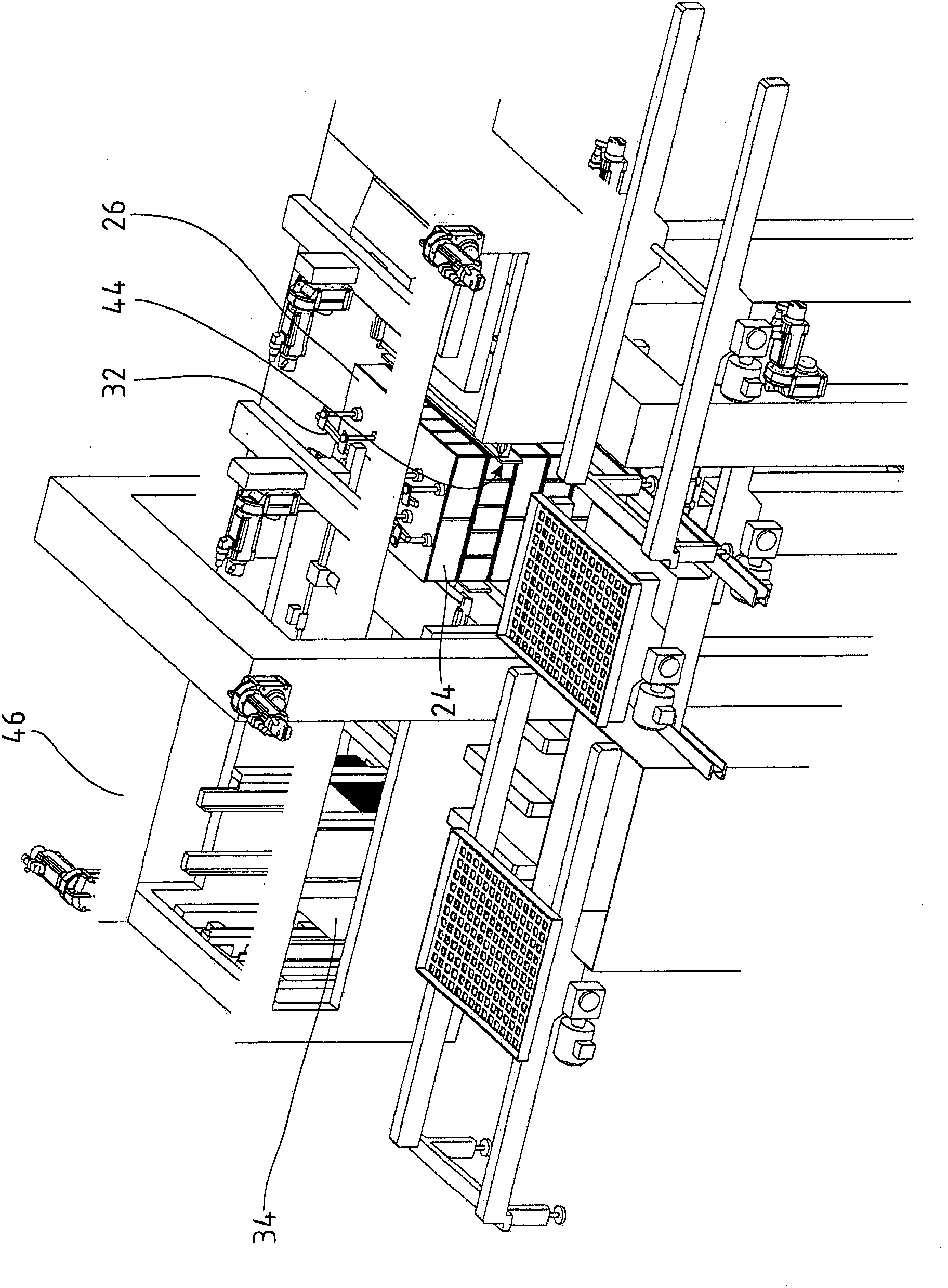

[0051] according to figure 1 As shown, the depalletizing system 1 according to the invention extends on two planes 2 , 4 , wherein pallets 6 containing products of the same type are conveyed fully automatically on a pallet transfer device 8 . The unpacked pallet 6 is then conveyed to a pre-centering unit 10 , which in the illustrated embodiment is embodied as a shaft centering element and, when a predetermined end position is reached, preferably on three sides, optionally The pallet 6 is also wrapped around on four sides (ie also from the conveying direction), so that the stack of products is centered on the pallet 6 in layers. use in figure 2 With the pallet lifting device 12 described in , the pre-centered full pallet 8 is then lifted in the vertical direction and transported to the level 2 . The depalletizing system has here two vertical supports 14, 16, which are covered by a door frame, and between which a pallet carrier 18 is guided, the pallet carrier being driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com