Plasma processing assembly including hinge assembly

A technology of plasma and hinge body, which is applied in the direction of plasma, electrical components, multi-purpose hand tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

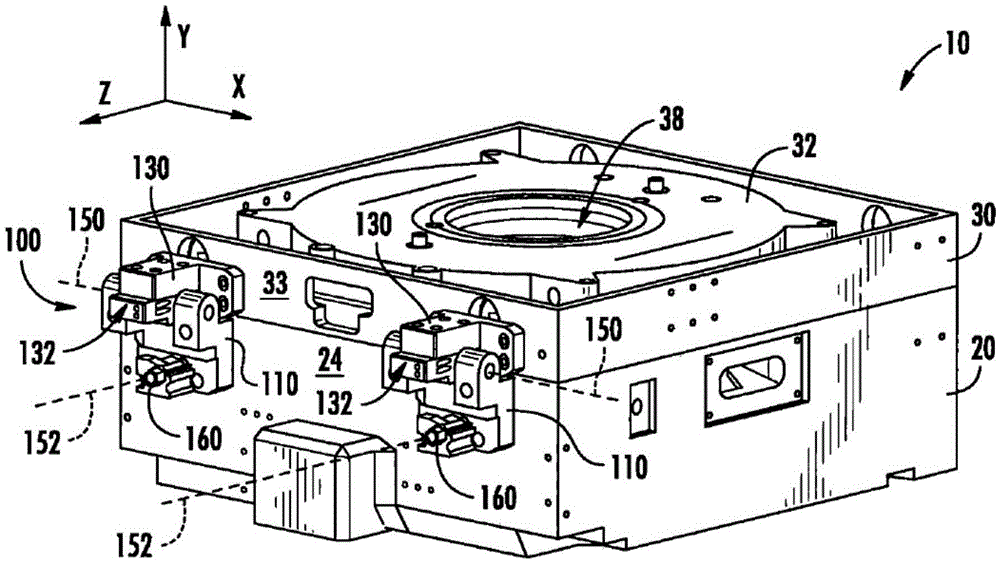

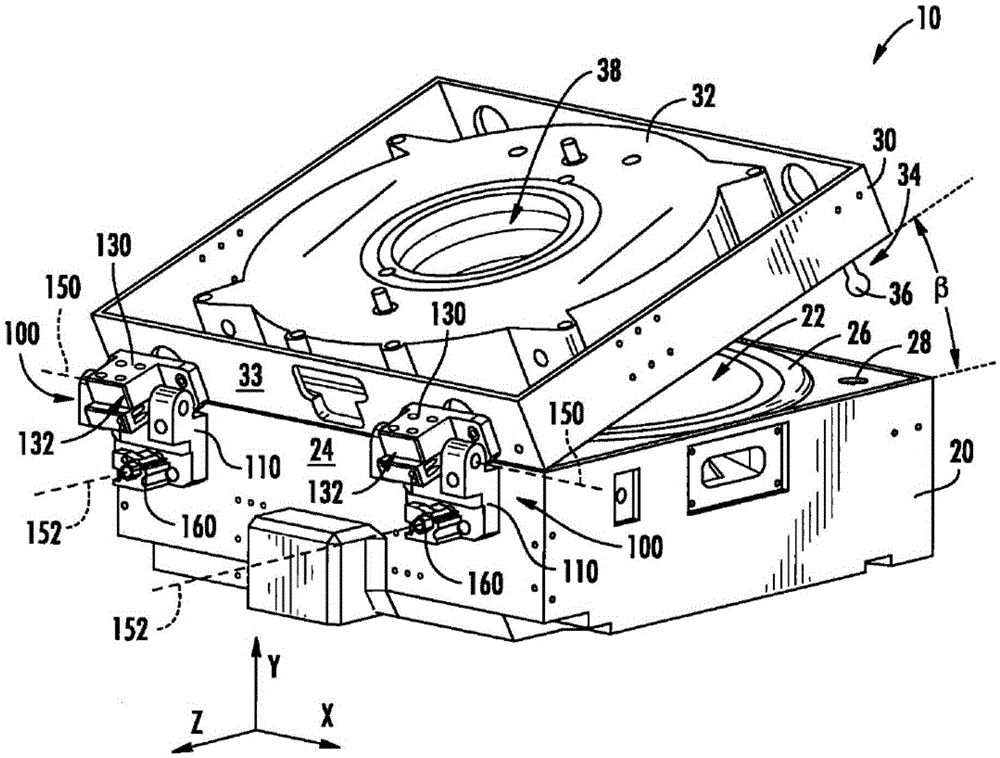

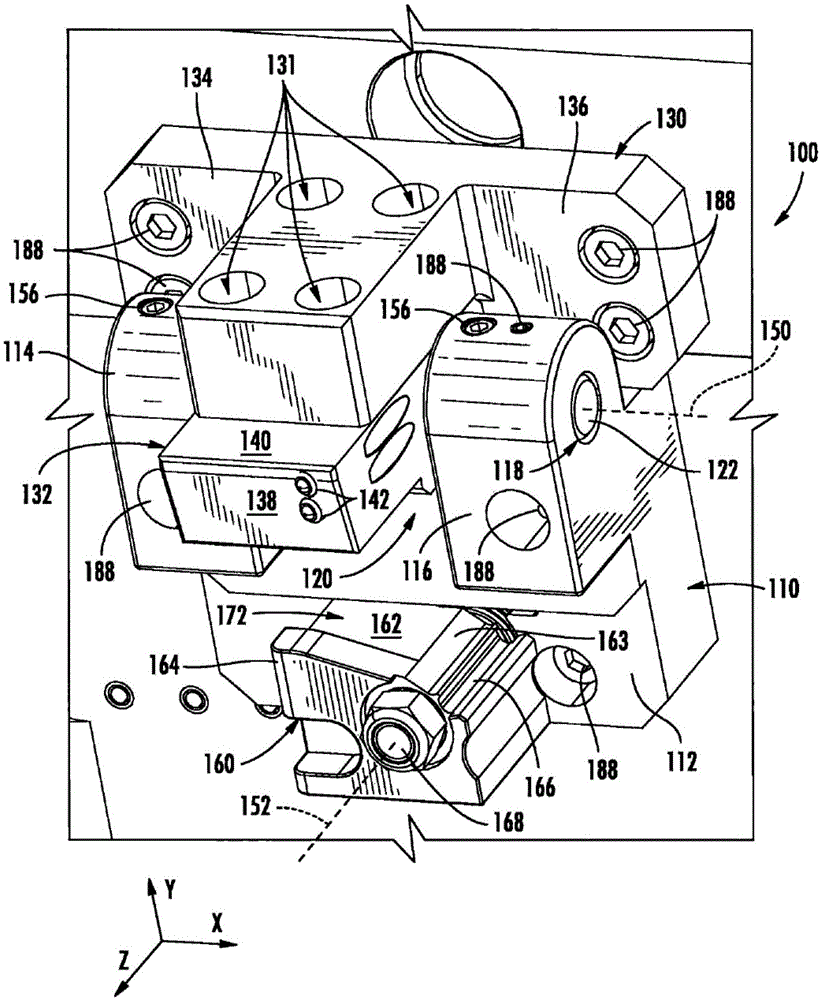

[0015] Figure 1 generally depicts one embodiment of a plasma processing assembly for etching material from and / or depositing material on a substrate. Plasma processing assemblies typically include an upper processing body pivotally engaged with a lower processing body by a hinge assembly. According to embodiments described herein, a hinge assembly generally includes a base hinge member pivotally engaged with a hinge body and a self-latch latch pivotally engaged with the base hinge member. Various embodiments of plasma processing assemblies and the operation of plasma processing assemblies are described in greater detail herein.

[0016] common reference Figure 1A and 1B , the plasma processing assembly 10 includes a lower processing body 20 having a lower vacuum chamber 22 formed in the lower processing body 20 for enclosing plasma processing. In plasma processing such as etching or deposition, the lower vacuum chamber 22 can enclose a plasma processing gas, for example, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com