A kind of method for preparing acyclovir tablet

A technology for oral tablets and prescriptions, which is applied in the field of acyclovir tablets and its preparation, can solve the problems of short time and cannot be used as an evaluation index to evaluate drug stability, so as to ensure dissolution, superior stability, and safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

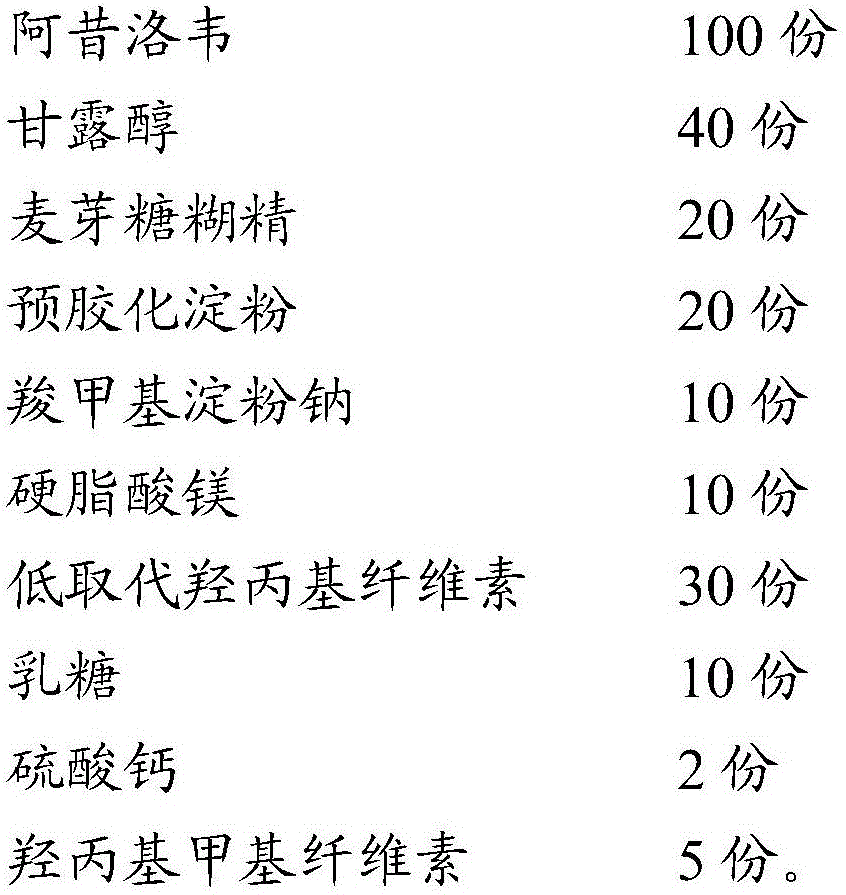

Embodiment 1

[0015]

[0016]

[0017] The preparation process is as follows: using the wet granulation process to compress tablets, taking acyclovir, mannitol, maltodextrin, pregelatinized starch, magnesium stearate, and sodium carboxymethyl starch in sequence, and mixing them in equal increments. Half of the prescription amount of low-substituted hydroxypropyl cellulose aqueous solution is made into a soft material, sieved and granulated, and air-dried at 80°C. After sieving and granulating, add the remaining low-substituted hydroxypropyl cellulose, lactose, hydroxyl Propyl methyl cellulose and calcium sulfate are uniformly mixed and pressed into tablets.

Embodiment 2

[0019]

[0020] The preparation process is as follows: using the wet granulation process to compress tablets, taking acyclovir, mannitol, maltodextrin, pregelatinized starch, magnesium stearate, and sodium carboxymethyl starch in sequence, and mixing them in equal increments. Half of the prescription amount of low-substituted hydroxypropyl cellulose aqueous solution is made into a soft material, sieved and granulated, and air-dried at 80°C. After sieving and granulating, add the remaining low-substituted hydroxypropyl cellulose, lactose, hydroxyl Propyl methyl cellulose and calcium sulfate are uniformly mixed and pressed into tablets.

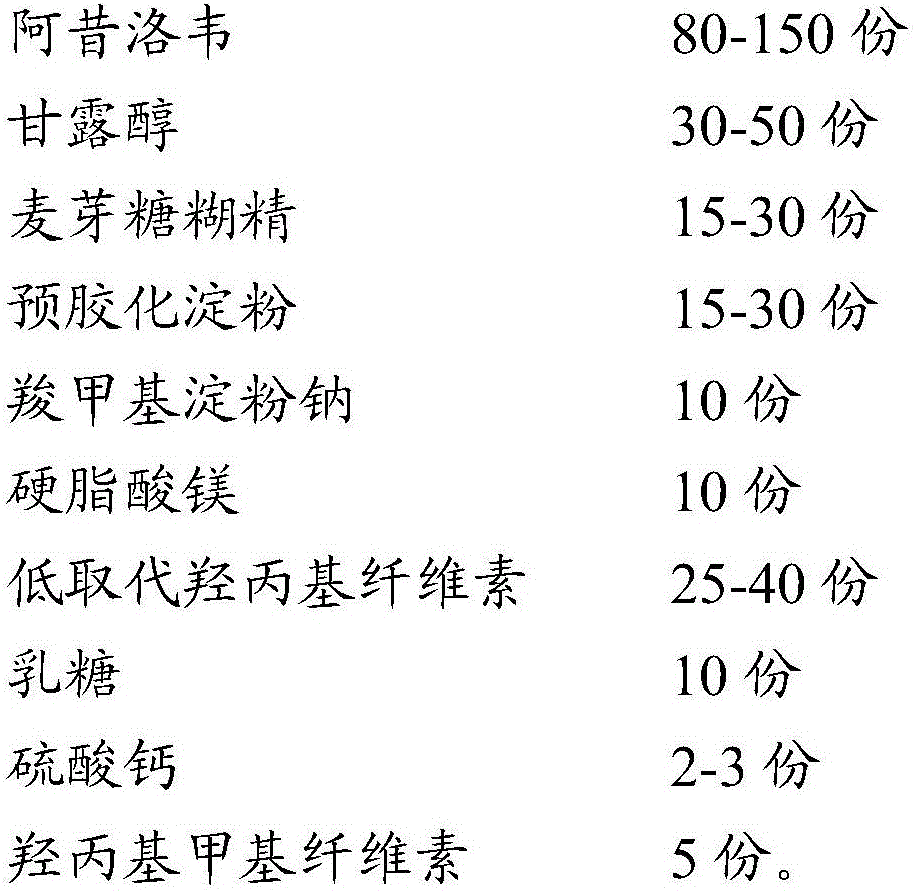

Embodiment 3

[0022]

[0023]

[0024] The preparation process is as follows: using the wet granulation process to compress tablets, taking acyclovir, mannitol, maltodextrin, pregelatinized starch, magnesium stearate, and sodium carboxymethyl starch in sequence, and mixing them in equal increments. Half of the prescription amount of low-substituted hydroxypropyl cellulose aqueous solution is made into a soft material, sieved and granulated, and air-dried at 80°C. After sieving and granulating, add the remaining low-substituted hydroxypropyl cellulose, lactose, hydroxyl Propyl methyl cellulose and calcium sulfate are uniformly mixed and pressed into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com