with turbo spiral filter assembly

A filter assembly and spiral technology, applied in the field of water treatment filtration system, can solve the problem that the filter material layer cannot be fully utilized, and achieve the effect of increasing the filtration effect and saving economic resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

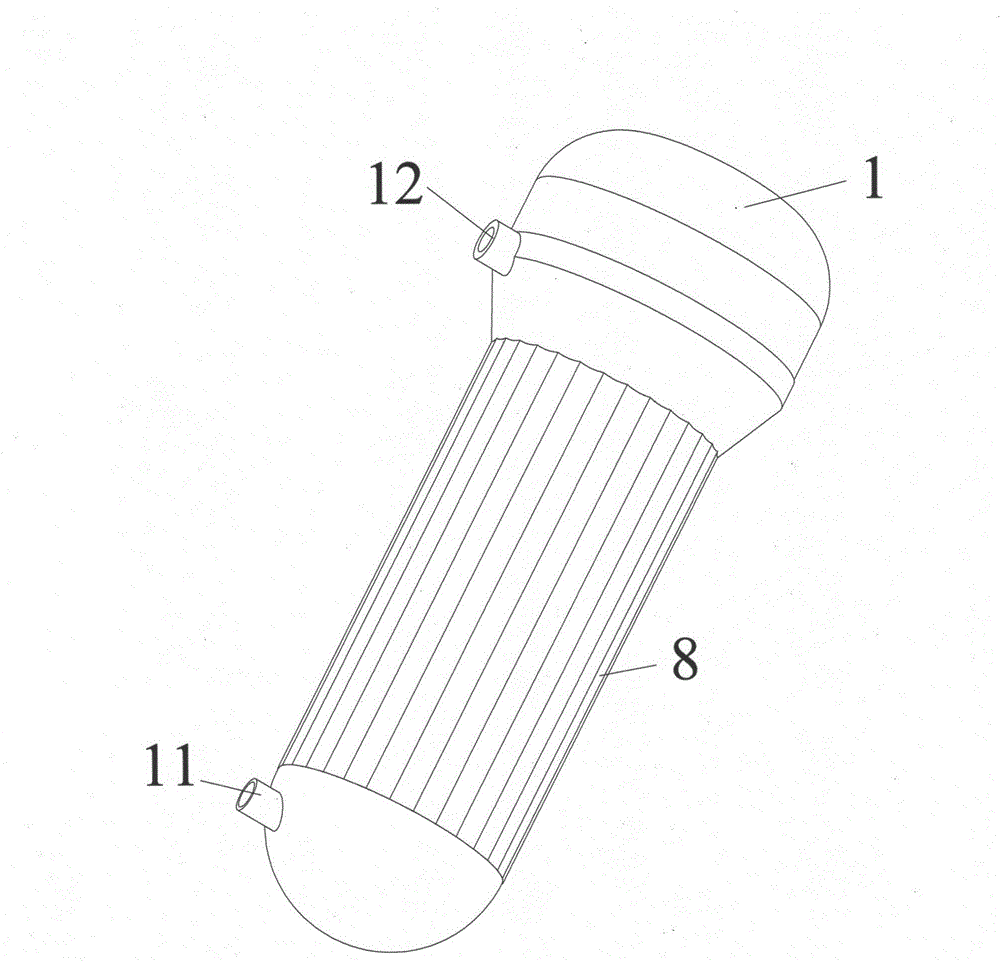

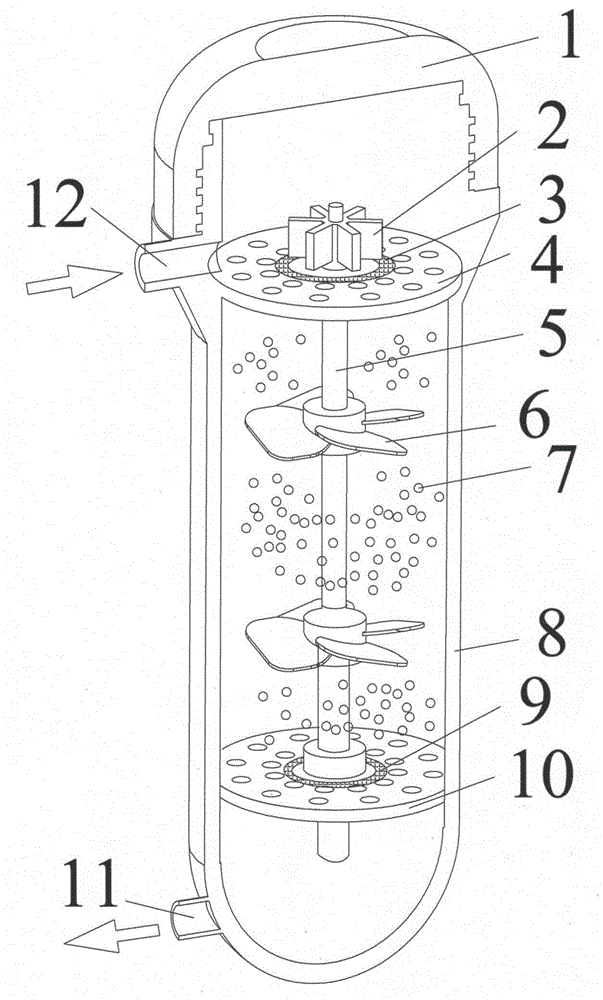

[0016] The present invention is a kind of filter assembly with turbine screw type, such as Figure 1-Figure 2 As shown, it includes a housing upper cover 1, the housing upper cover 1 and the housing lower cover 8 can be connected by threaded connection or spin melting process, the upper part of the housing lower cover 8 has a water inlet 12, and the lower part of the housing lower cover 8 has a water outlet 11. The first porous buffer plate 4 and the second porous buffer plate 10 are fixed between the water outlet 11 and the water inlet 12 in the lower shell 8, and the first porous buffer plate 4 and the second porous buffer plate 10 Close to the inner wall of the lower cover 8 of the housing and fix it. The granular filter material 7 is placed between the first porous buffer plate 4 and the second porous buffer plate 10 in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com