Vertical stirring apparatus

A stirring device, vertical technology, applied in the field of vertical stirring devices, can solve the problems of high height of the mixer, not suitable for disc-shaped mixing containers, unfavorable maintenance, etc., and achieve the goal of reducing the overall height, simple and reasonable structure, and easy installation and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

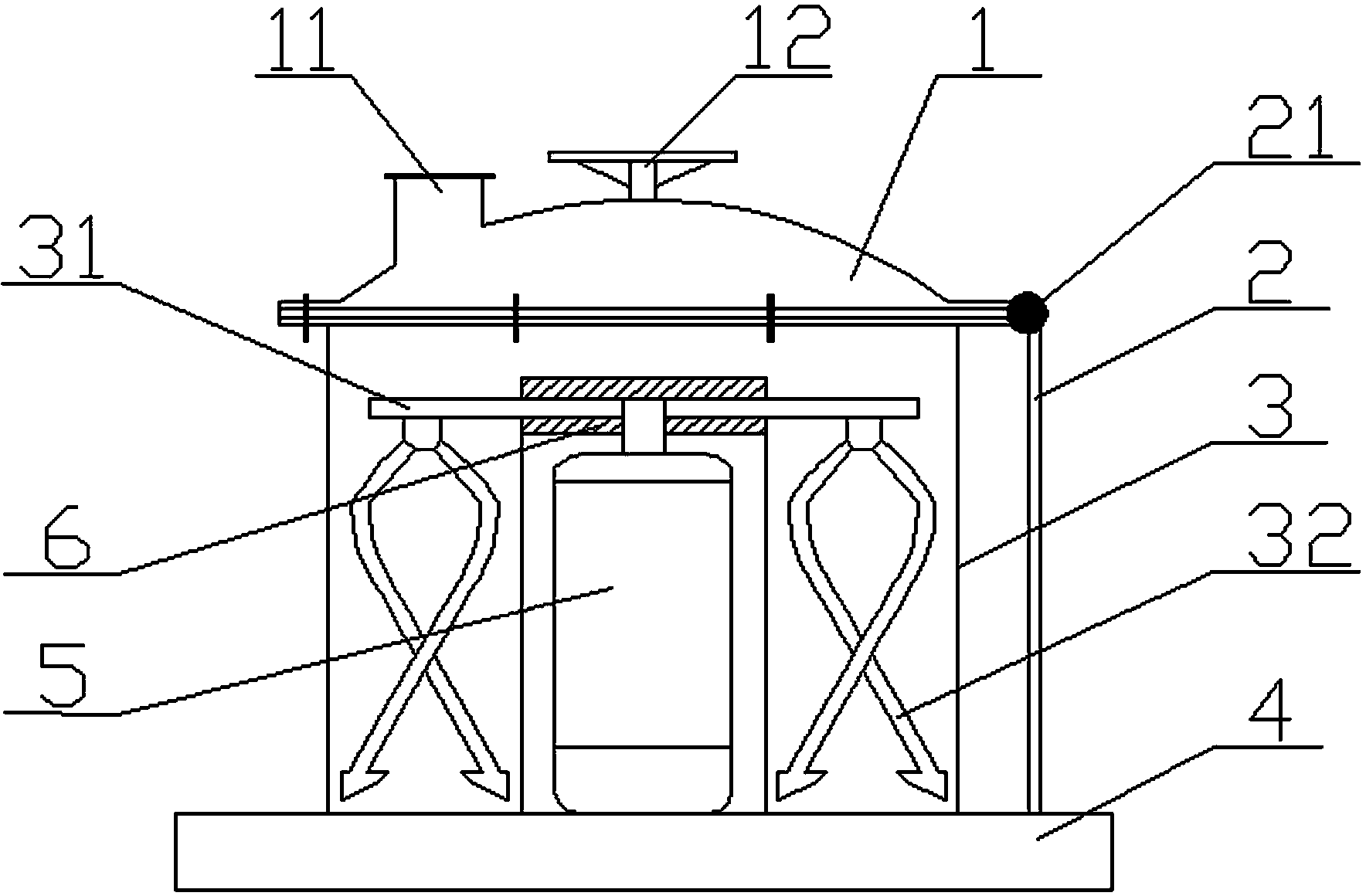

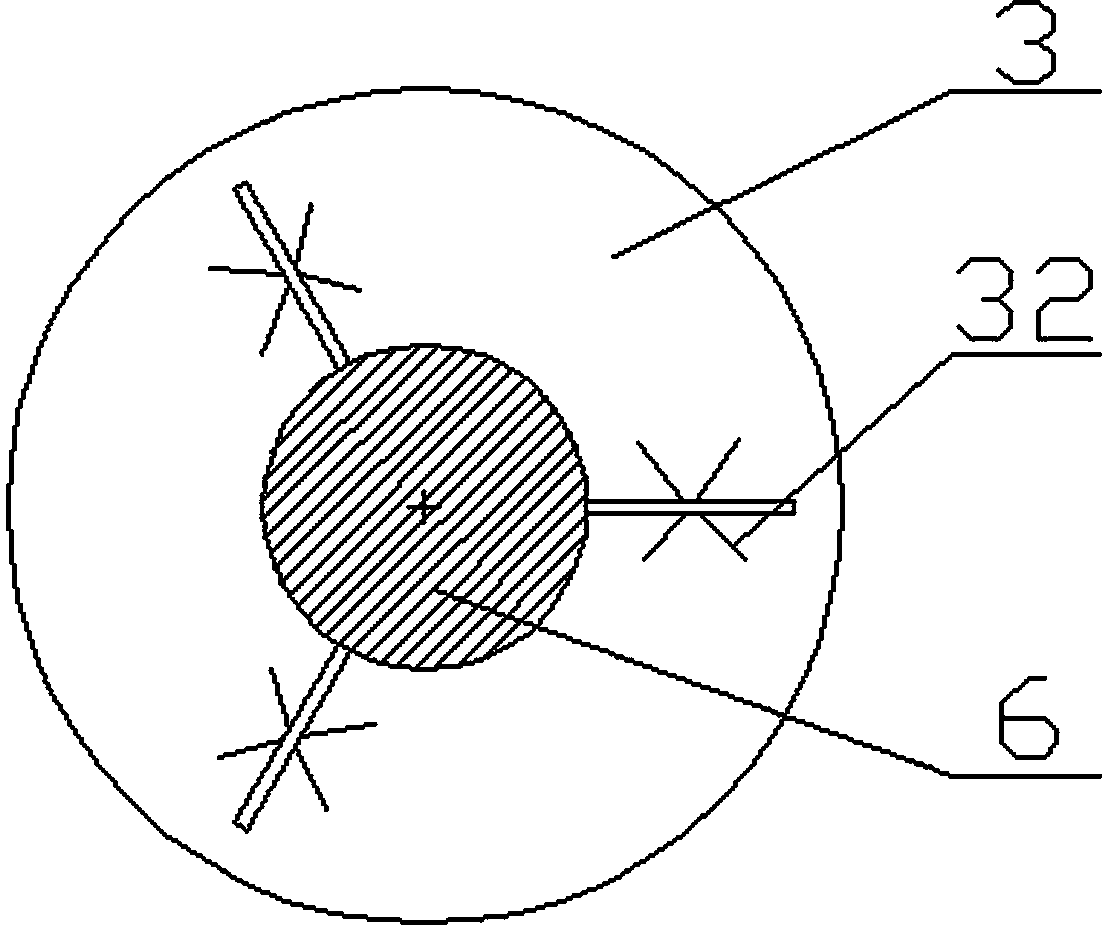

[0015] like Figure 1 to Figure 2 As shown, a vertical stirring device includes a feeding port 11, an upper cover 1, a disc-shaped stirring container 3, a coupling rod 31, a stirring rod 32, a motor 5, an L-shaped fixing plate 2 and a base 4, and feeding The mouth 11 is located on the upper cover 1, and the top center of the upper cover 1 is fixed with a circular handle 12. The fixed plate 2 includes a horizontal plate and a vertical plate, which are flexibly connected by a hinge 21 between the horizontal plate and the vertical plate. The upper cover 1 has a circular hole matching the size, and the upper cover 1 is fixed on a horizontal plate located around the circular hole. The horizontal plate is detachably connected with the stirring container 3 through fixing bolts, so that the upper cover can be easily connected by the ring handle 12. 1 Take it out from the top of the stirring container 3, and the vertical plate is fixed on the base 4. The motor 5 is disposed at the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com