Claw clamping connecting and disconnecting mechanism of AGV (Automatic Guided Vehicle) robot

A claw-holding, robotic hand technology, applied in traction connectors, transportation and packaging, vehicle parts, etc., can solve problems such as poor economy, bloated installation and removal boards, and achieve convenient positioning, simple shelf structure, and low wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

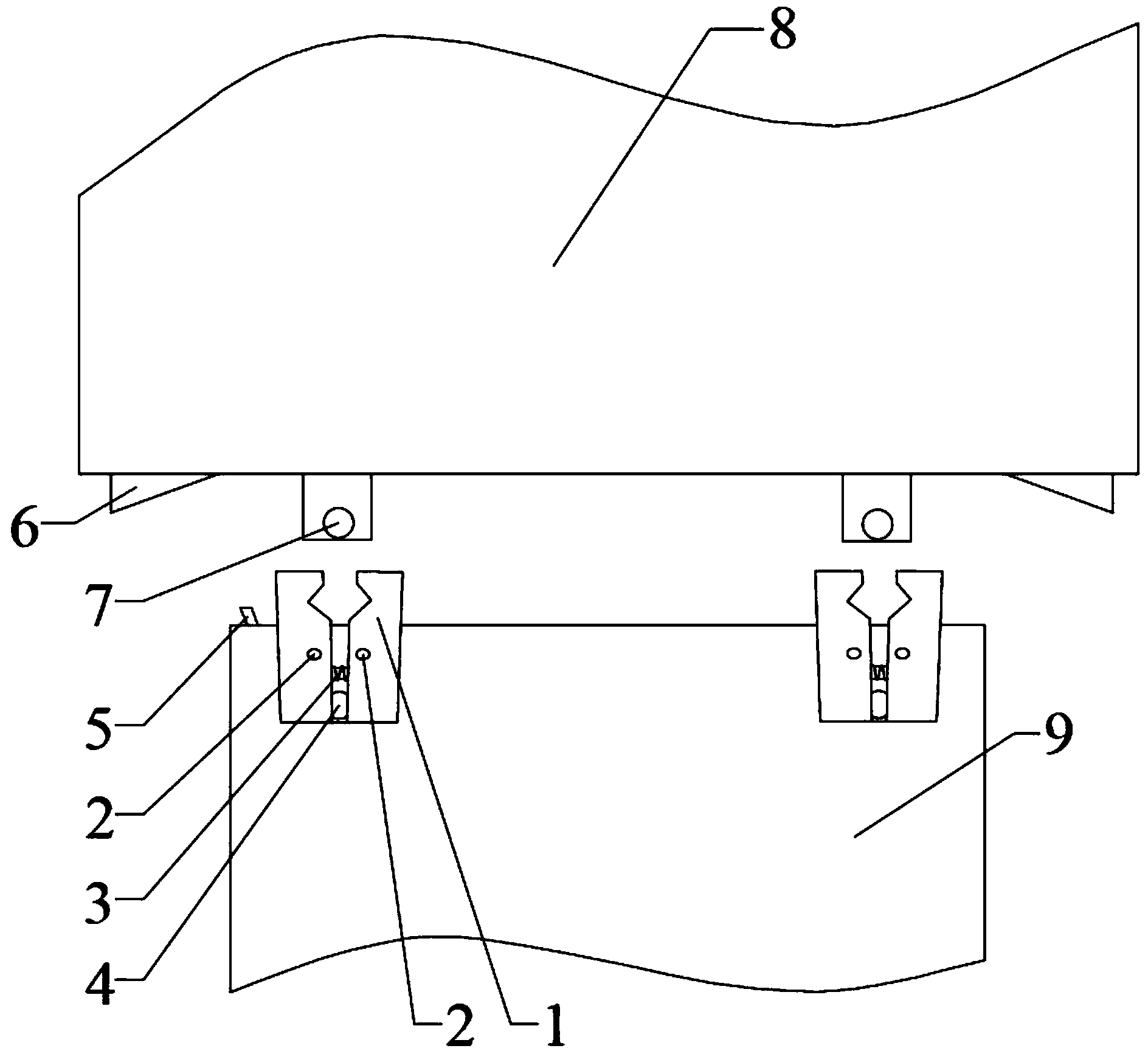

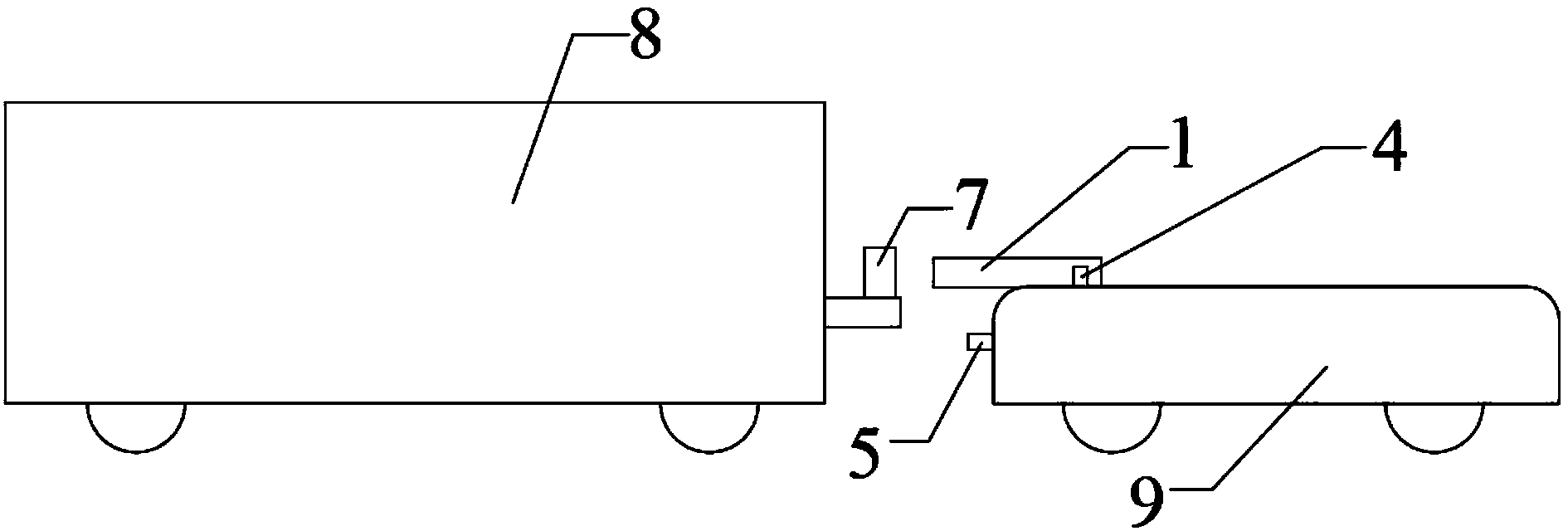

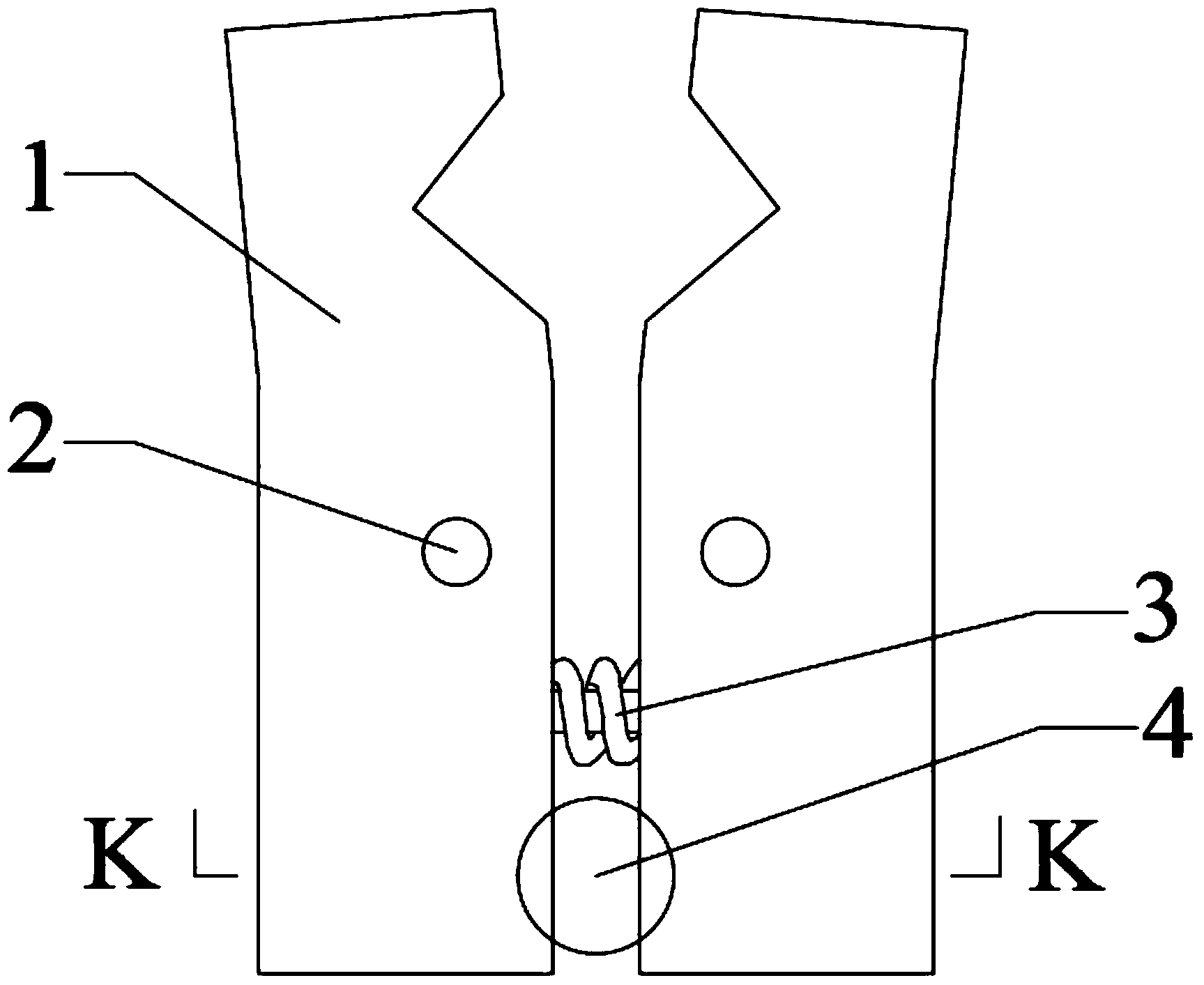

[0017] The present invention provides an AGV robot claw clamping type connecting and disconnecting mechanism, such as figure 1 and figure 2 As shown, it includes two fixed pins 7 arranged on the shelf 8, and two lifting and closing claw clamping mechanisms arranged on the AGV9, and the fixed pins 7 correspond to the lifting and closing claw clamping mechanisms one by one; image 3 As shown, the lifting and closing type claw clamping mechanism is composed of a lifting pin mechanism 4, a spring 3, a V-shaped claw 1, and a rotary hinge 2. The lifting pin mechanism 4 is fixed on the AGV9. Lifting pin, the driving ends of the two V-shaped claws 1 are respectively located on both sides of the lifting pin mechanism 4, and the two ends of the spring 3 are respectively connected to the driving ends of the two V-shaped claws 1, and the V-shaped claw ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap