Medium partition plate bin

A technology of partitions and partitions, which is applied in the direction of conveyor objects, unstacking, transportation and packaging of objects, which can solve the problems of occupying a large temporary storage space, high labor intensity, and difficult placement of partitions, and achieve Improve space utilization, reduce production costs, and save floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the description:

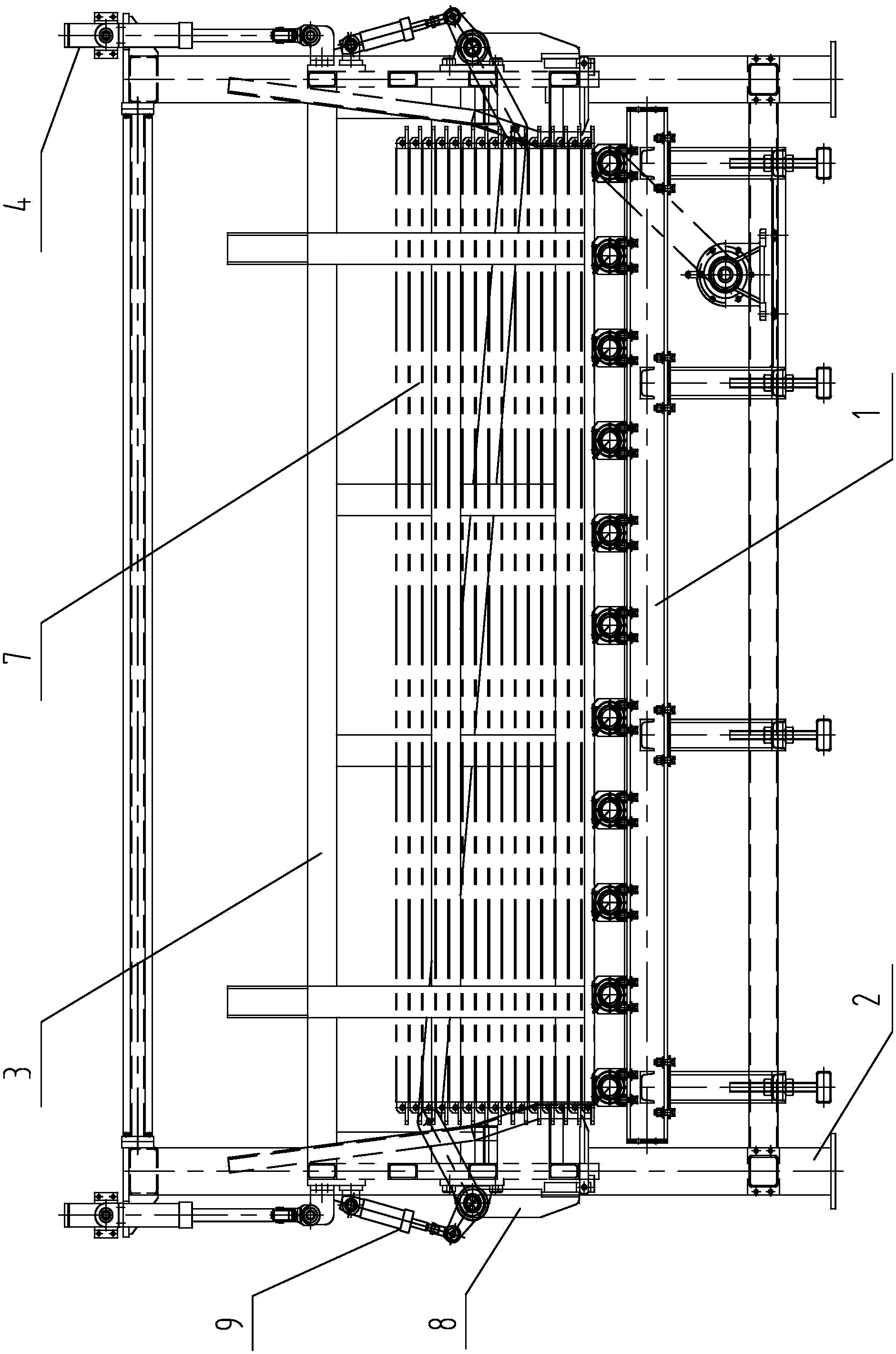

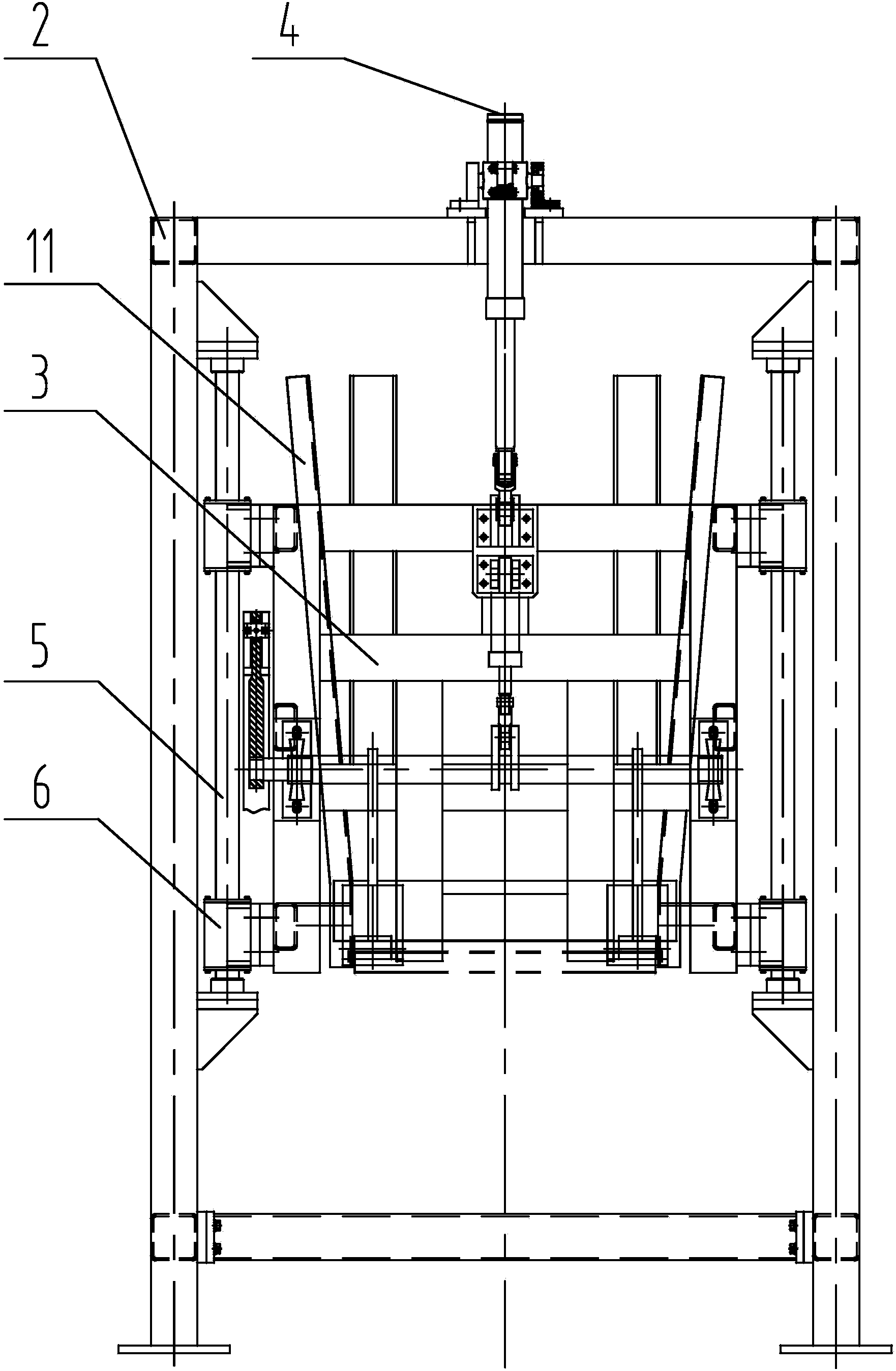

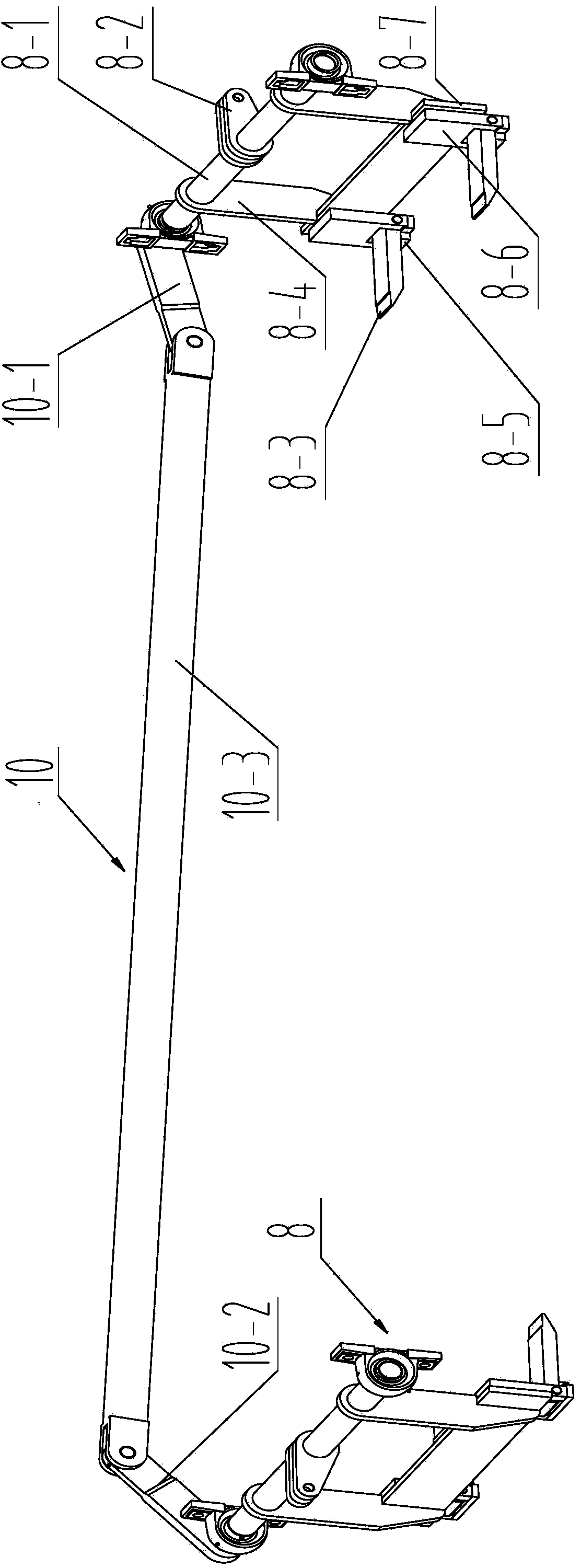

[0026] Such as figure 1 - Figure 4 As shown, it is a partition warehouse provided by the present invention, which includes a partition support 2 used in conjunction with a partition conveying line 1, and the partition conveying line 1 starts from the middle of the partition support 2 Pass through, the silo support 2 is provided with a lifting frame 3 located above the middle partition conveying line 1 and a lifting drive device connected between the silo support 2 and the lifting frame 3 to drive the lifting frame 3 up and down 4;

[0027] The guide column 5 is fixedly installed on the board warehouse support 2; the guide sleeve 6 that is movably connected with the guide column 5 is provided on the lifting frame 3, and the lifting frame 3 is guided along the guide column 5 through the guide sleeve 6. Move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com