A kind of spun yarn containing nylon and its production method and application

A nylon staple fiber and fiber yarn technology is applied to nylon-containing staple fiber yarn and its production field, and can solve the problems of rarely used clothing, poor evenness, and poor dyeing uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

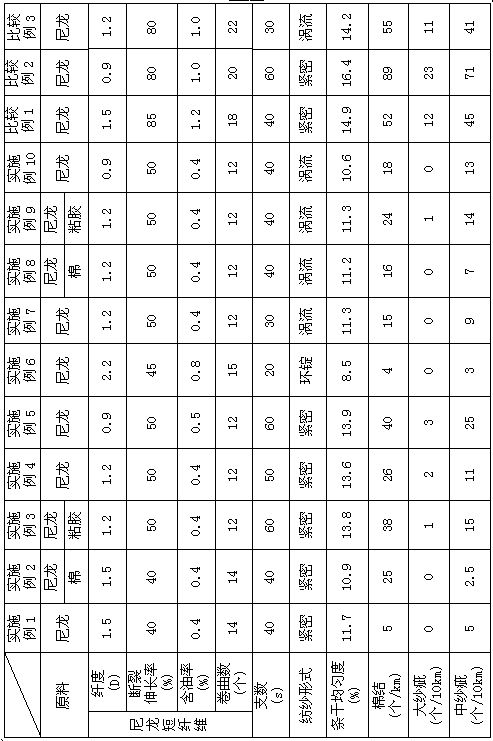

Examples

Embodiment 1

[0033] Using the compact spinning process, the nylon 6 (NY6) raw cotton with an elongation at break of 40%, an oil content of 0.4%, a number of crimps of 14, and 1.5D*38mm is prepared as raw cotton (antistatic treatment)→cleaning and winding →Carding→drawing→roving→spinning→winding process for spinning to obtain 40s NY100% spun yarn.

[0034] The specific conditions of the above projects are as follows:

[0035] Raw cotton preparation: first prepare the antistatic agent and water according to the ratio of 2:100, then spray it evenly around the cotton bale according to the amount of 0.5L / 100kg, wrap it in a plastic bag after spraying, and place it for 24 hours;

[0036] Cleaning and rolling: the weight is controlled between 340 and 350g / m;

[0037] Carding: raw sliver basis weight 18g / 5m, flat to cylinder gauge 9 / 8 / 8 / 8 / 9, doffer speed 16rpm, licker-in roller 780rpm, cylinder 330rpm, sliver delivery speed 70m / min;

[0038] Draw frame: twice draw frame; 1 parallel 20g / 5m, 2 par...

Embodiment 2

[0043] Adopt compact spinning process, the NY6 raw slivers obtained after carding in Example 1 and the combed slivers formed by Xinjiang 229 combed cotton are drawn 3 times, and 1 mixed sliver 20g / 5m, 2 mixed sliver 18g / 5m during drawing , 3 and 18g / 5m, then carry out roving, spun yarn, winding project with embodiment 1, obtain the NY short fiber yarn of 40s, in the gained short fiber yarn, NY short fiber content is 50%, cotton content is 50%.

[0044] Among them, Xinjiang 129 carding raw sliver weight is 16g / 5m, cover plate to cylinder gauge is 8 / 7 / 7 / 7 / 8, doffer speed is 16rpm, licker-in roller is 880rpm, cylinder is 330rpm, and sliver delivery speed is 70m / min; When combing, the combed sliver weight is 16g / 5m, and the combed noil rate is 21%.

Embodiment 3

[0046]Using the compact spinning process, the NY6 raw cotton with an elongation at break of 50%, an oil content of 0.4%, a number of crimps of 12, and 1.2D*38mm was subjected to antistatic treatment according to the method of Example 1, and then mixed with 1.2 D*38mm viscose staple fibers are torn and mixed (artificially blended cotton). Take 300kg as a part. In each part, nylon accounts for 180kg and viscose accounts for 120kg. Prepare 4 parts, totaling 1200kg, and put them into the disc to grab cotton In the machine, it is used for the back road, and then carry out the cleaning and rolling, carding, drawing, roving, spun yarn, and winding engineering of the same embodiment 1 to obtain the NY staple yarn of 60s, and the NY staple fiber in the gained staple yarn The content is 60%, and the cotton content is 40%. Among them, the sliver weight in the roving project is 3.4g / 10m, and the twist coefficient is 0.7.

[0047] Artificial blending can fully mix two kinds of raw cotton ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com