engine air filter

An engine air filter and filter element technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems that the filter element and the sealing sleeve cannot be effectively aligned, the sealing effect is affected, and the rubber ring is easy to loosen, etc. Rubber ring sealing structure, realize automatic centering and positioning, and eliminate the effect of wrong installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment. It should be understood that the "upper", "lower", "left", "right", "front" and "reverse" mentioned in the following embodiments of the present invention are all based on the directions shown in the figures, These words used to limit the direction are only for convenience of description, and do not mean to limit the specific technical solution of the present invention.

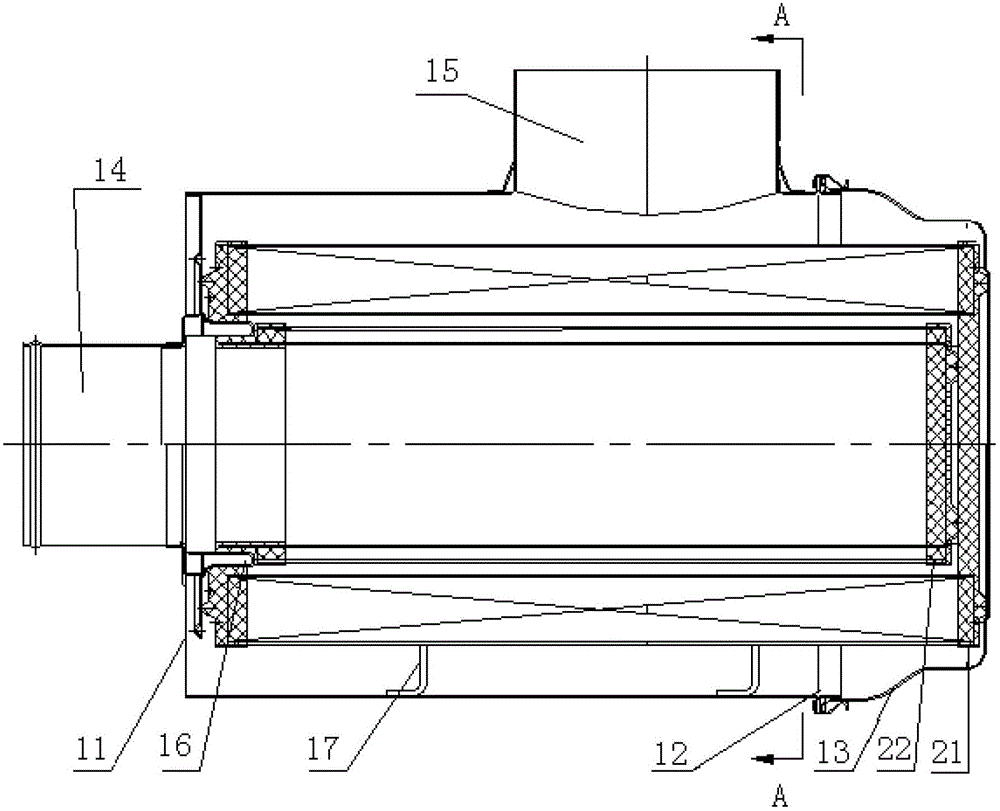

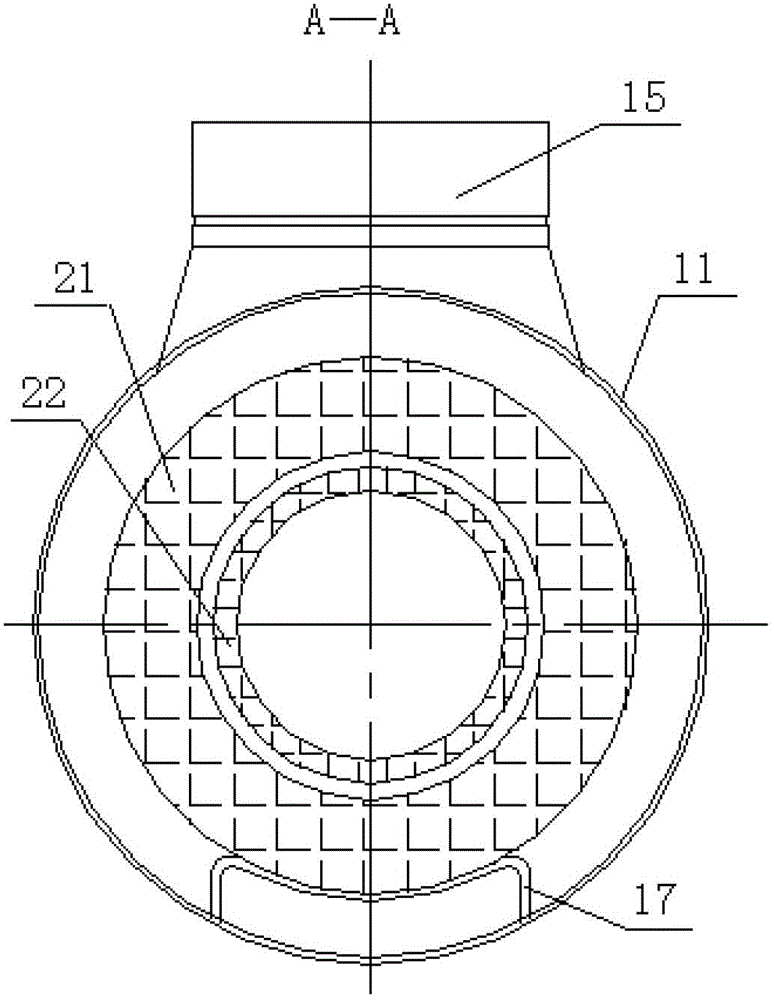

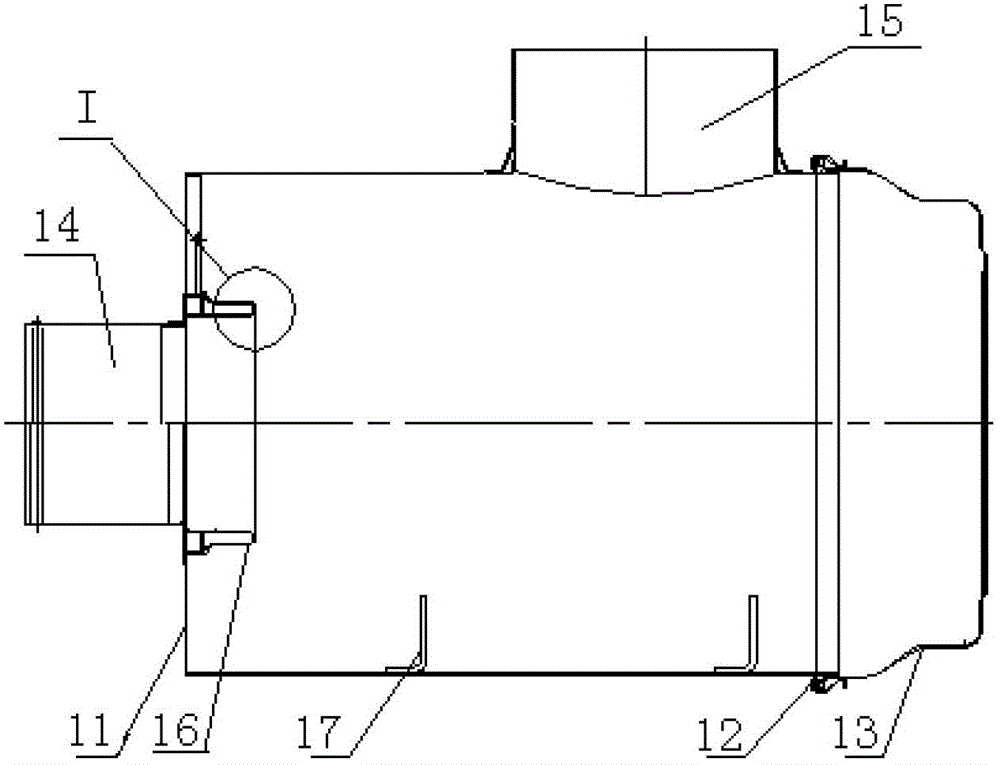

[0022] The engine air filter of the present invention adopts sealing sleeves and filter element positioning brackets with sealing tapered double-walls and circular arc guide surface structures to realize automatic centering and positioning of the filter element, which facilitates the insertion of the main filter element and the safety filter element, and maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com