High supercharged engine intake port and designing method

A supercharged engine and design method technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problem that the intake port is difficult to play a good role

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

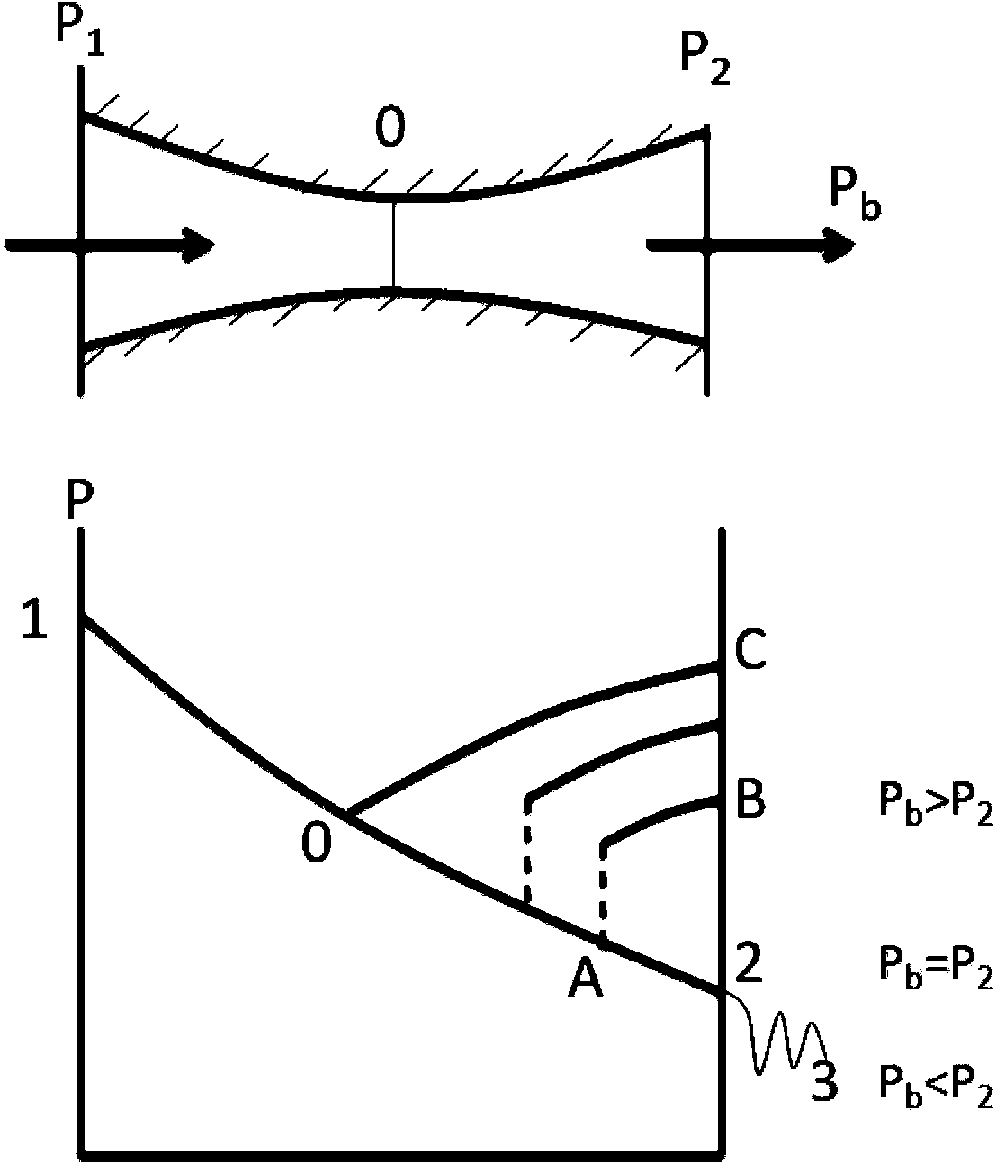

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

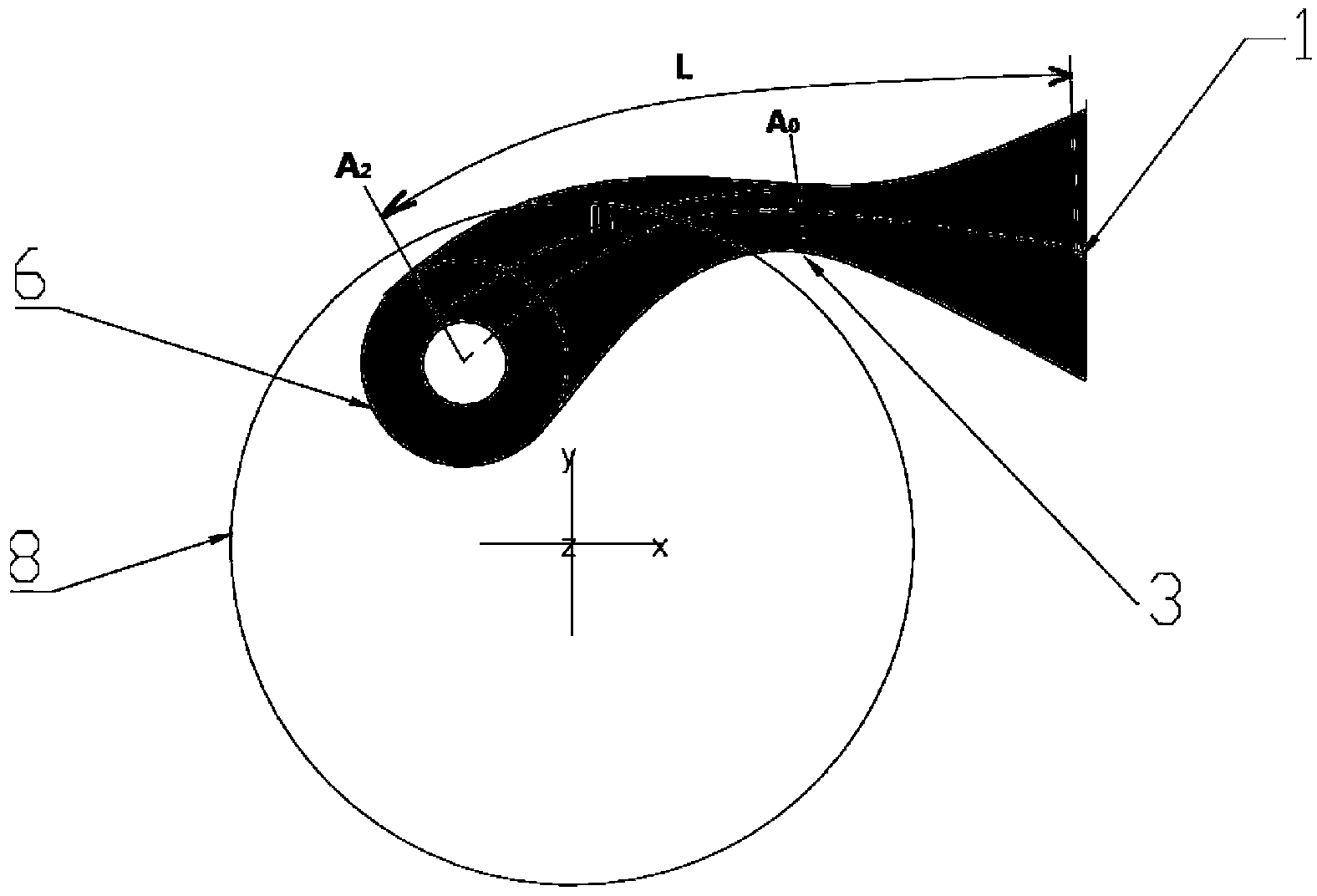

[0034] A practical design example of the present invention is illustrated below by taking the design of the air inlet of a certain type of high-pressure diesel engine as an example.

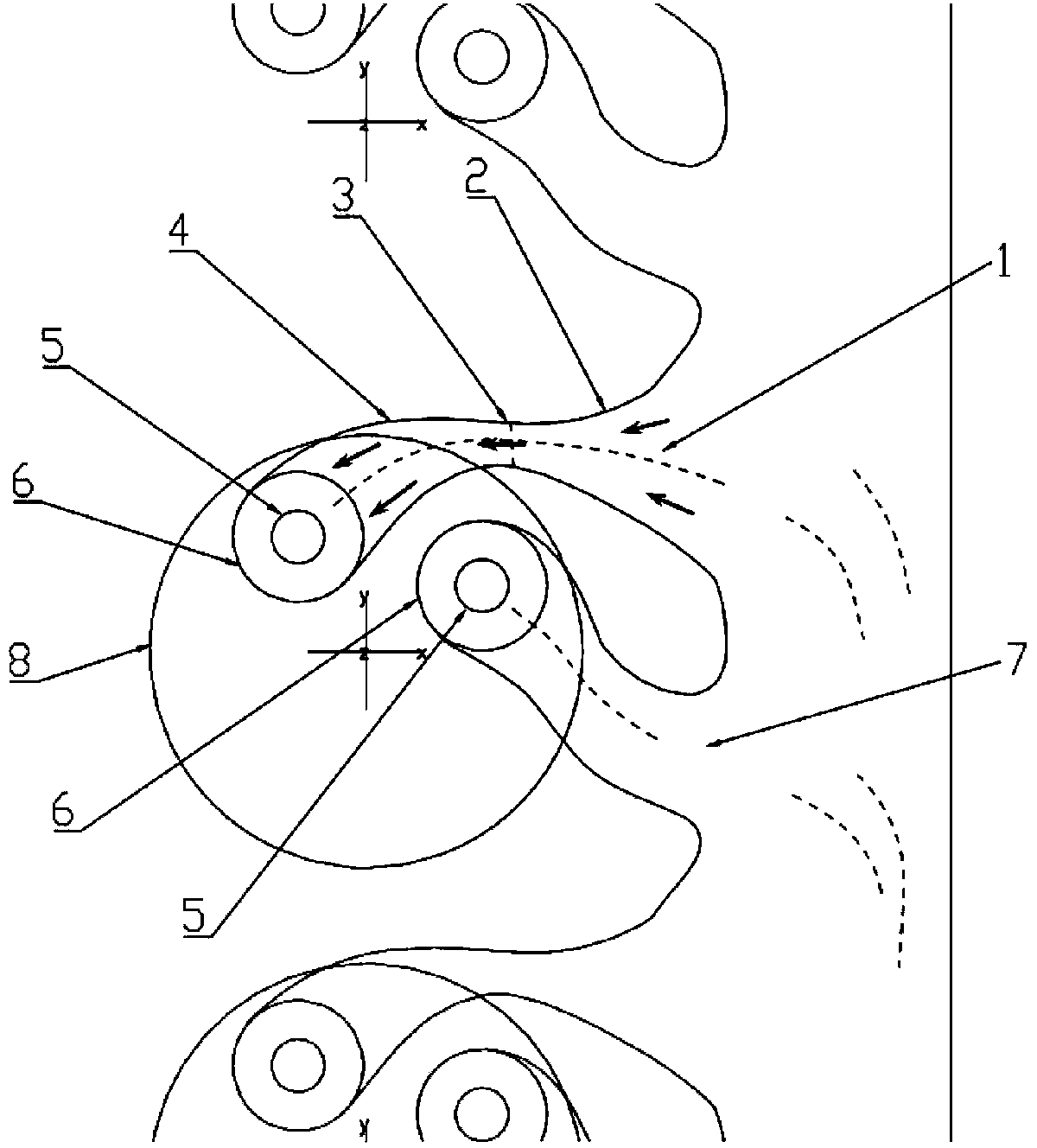

[0035] Such as figure 2 , 3 Is the schematic diagram of the intake port of the high boost engine. The air intake includes a constriction section 2 and a divergence section 4 , the transition from the constriction section 2 to the divergence section 4 is the inlet throat 3 .

[0036] image 3 Shown is a schematic diagram of the size of a high boost engine intake port and design method of the present invention.

[0037] 1) Determine the gas temperature T at the inlet inlet according to the characteristic data of the supercharger 1 is 358.15K, pressure P 1 3.5bar, gas flow rate C 1 It is 80m / s. Inlet outlet design back pressure p 2 Selected as 2.9bar.

[0038] According to the cylinder arrangement, the inlet port outlet diameter d 2 =33.2mm 2 , so the inlet cross-sectional area A 2 789....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com