Locking cylinder structure with cushioning at the end of stroke

A technology for locking cylinders and strokes, which is applied in the direction of fluid pressure actuation devices, etc., which can solve the problems of low cylinder locking speed and affecting the important performance of servo tool holders - tool change speed, large cylinder locking force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

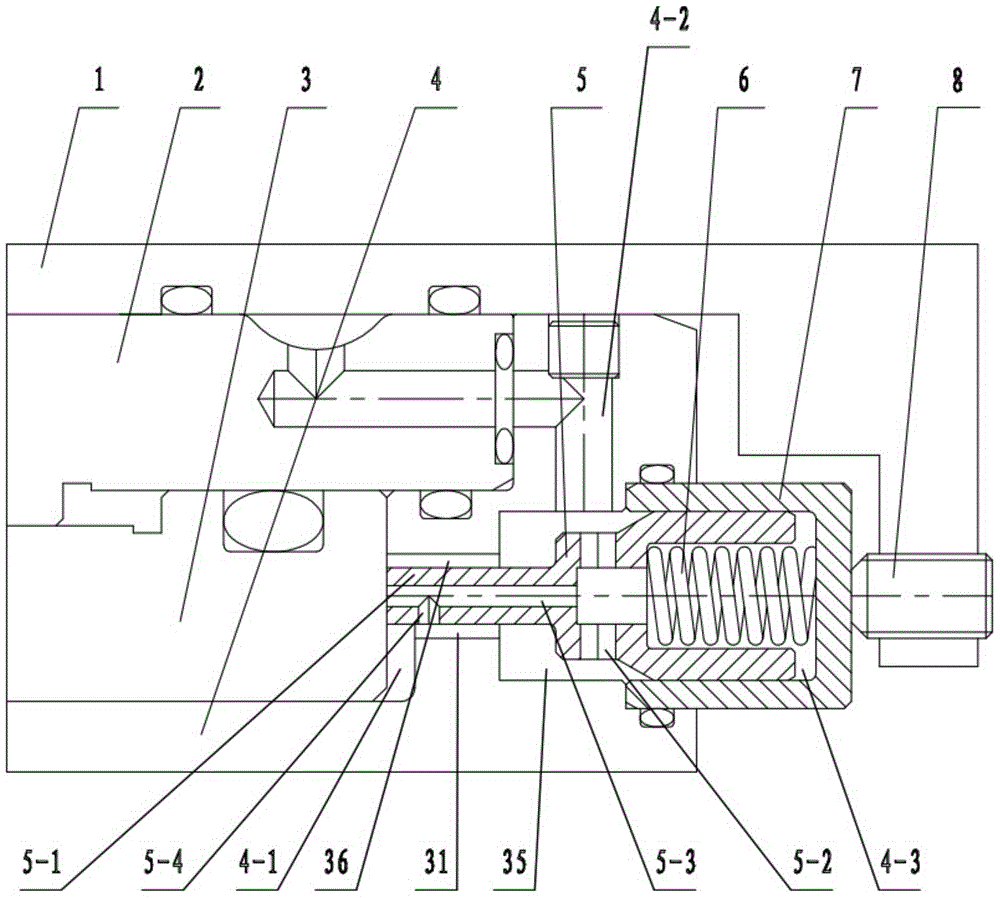

[0012] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a locking cylinder structure with stroke end cushioning includes a cylinder seat 4, a cushion valve sleeve 7, a cushion valve core 5, a piston 3 and a spring 6, and the cylinder seat 4 has an oil supply channel and a cylinder chamber 4-1. The buffer valve sleeve 7 is installed on the cylinder seat 4, the piston 3 is located in the cylinder cavity 4-1, the buffer valve core 5 is slidingly fitted in the buffer valve sleeve 7, and the spring 6 is arranged on one end of the buffer valve core 5 and the buffer valve sleeve 7 Between, the other end of the buffer spool 5 extends into the cylinder chamber 4-1, and a large flow passage and a small flow buffer passage for supplying oil to the cylinder chamber 4-1 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com