Energy-saving and environment-friendly boiler tail gas discharge tower

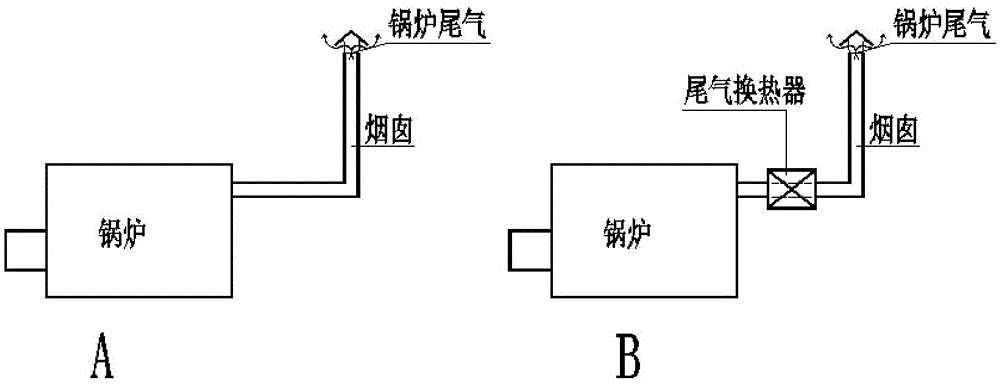

A tail gas emission, energy saving and environmental protection technology, applied in the direction of lighting and heating equipment, can solve the problems of difficult installation, high renovation cost, ignoring the impact of the environment, etc., and achieve the effect of beautiful appearance and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

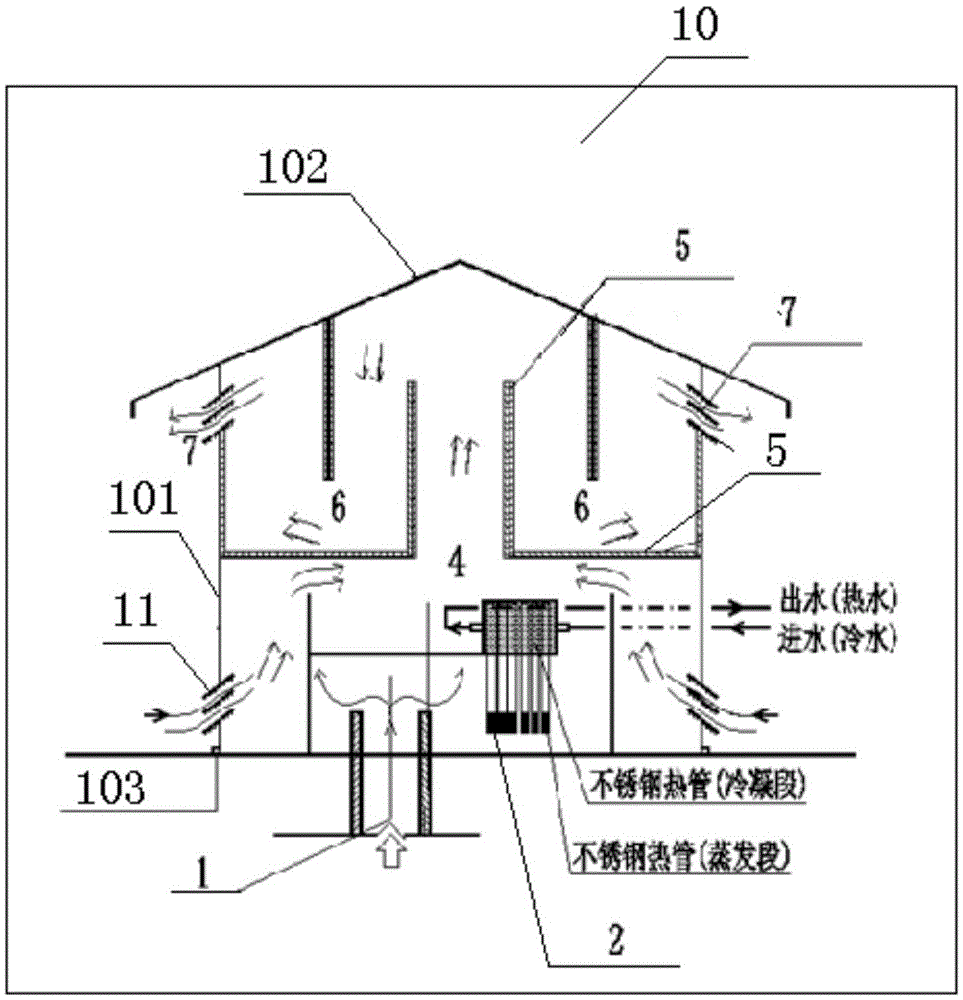

[0029] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0030] see figure 2 , an energy-saving and environment-friendly boiler tail gas discharge tower provided by an embodiment of the present invention includes a discharge tower body 10, wherein:

[0031] The middle part of the bottom of the exhaust tower body 10 is provided with an exhaust gas inflow flue 1 and an exhaust heat recovery device 2; The other end is in contact with the surface of the exhaust heat recovery device 2; the bottom of the discharge tower body 10 is provided with outdoor cold air inlets 11; The treated boiler exhaust gas is jointly directed to the middle collision chamber 4 of the discharge tower body 10;

[0032] The top of the discharge tower body 10 is distributed with two overall S-shaped exhaust flues 6 from the middle to both sides, and the two sides of the top are provided with mixed e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com