A construction technique for building a photovoltaic power station on the water surface

A technology of photovoltaic power station and construction technology, which is applied in the field of solar photovoltaic, can solve the problems of inconvenient installation and difficulty in building a power station, and achieve the effect of simple and convenient installation structure, no damage to the ecological environment, and beautifying the landscape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

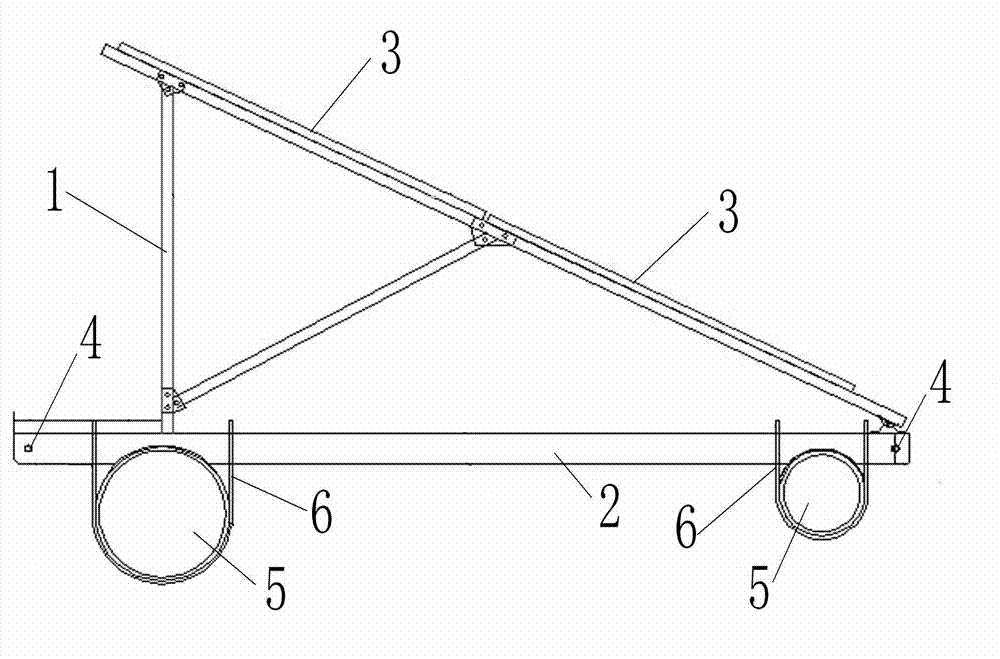

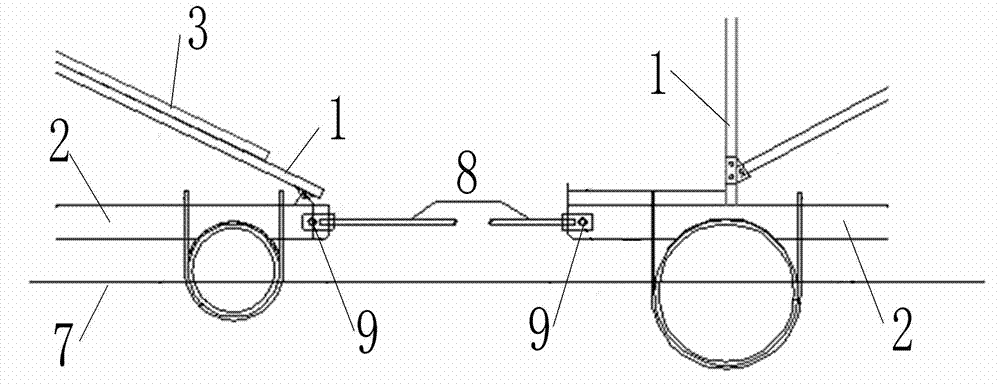

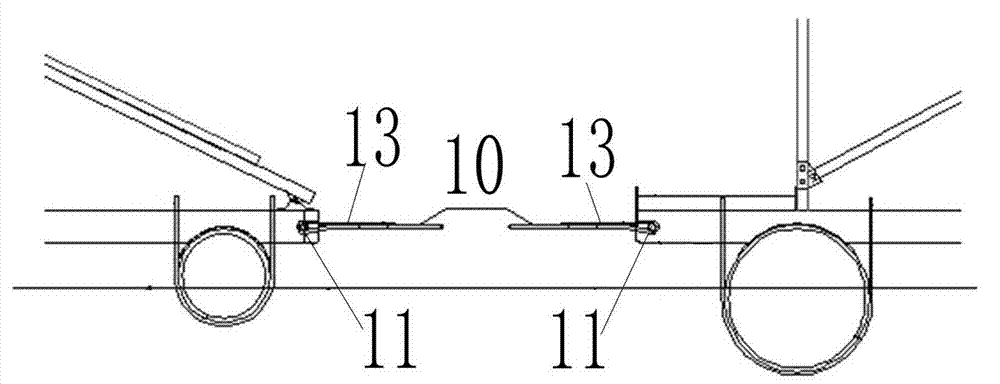

[0020] Attached below figure 1 , attached figure 2 The present invention will be further described.

[0021] The construction process of building a photovoltaic power station on this water surface includes the following steps:

[0022] (1) Dig a number of pits under the water surface at 12 shore foundations around the water area, then pour concrete to make the foundation 18, and pre-embed the column 14 when pouring the concrete; (2) Insert the slider 15 onto the column 14, Install and fix a buoy II 17 at the bottom of the slider 15; (3) Fix the triangular bracket 1 above the horizontal beam 2, and then fix the two buoys I 5 to the lower ends of the beam 2 through U-shaped bolts 6 , and then fix the photovoltaic modules 3 to the inclined surface of the support (1) to form a square array of photovoltaic power stations; (4) several square arrays of photovoltaic power stations are fixed in the screw holes 4 at the front and rear ends of the beam 2 through connecting rods 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com