Rotor assembly

A rotor and component technology, applied in the direction of electric components, magnetic circuit rotating parts, electrical components, etc., can solve the problems of no performance, high cost, excessive generator structure, etc., and achieve the effect of logistics improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

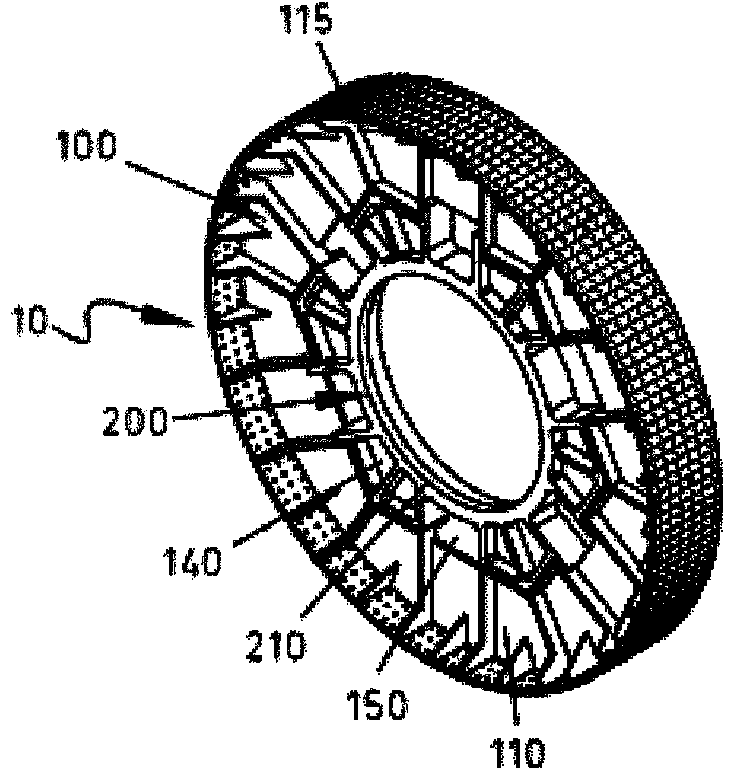

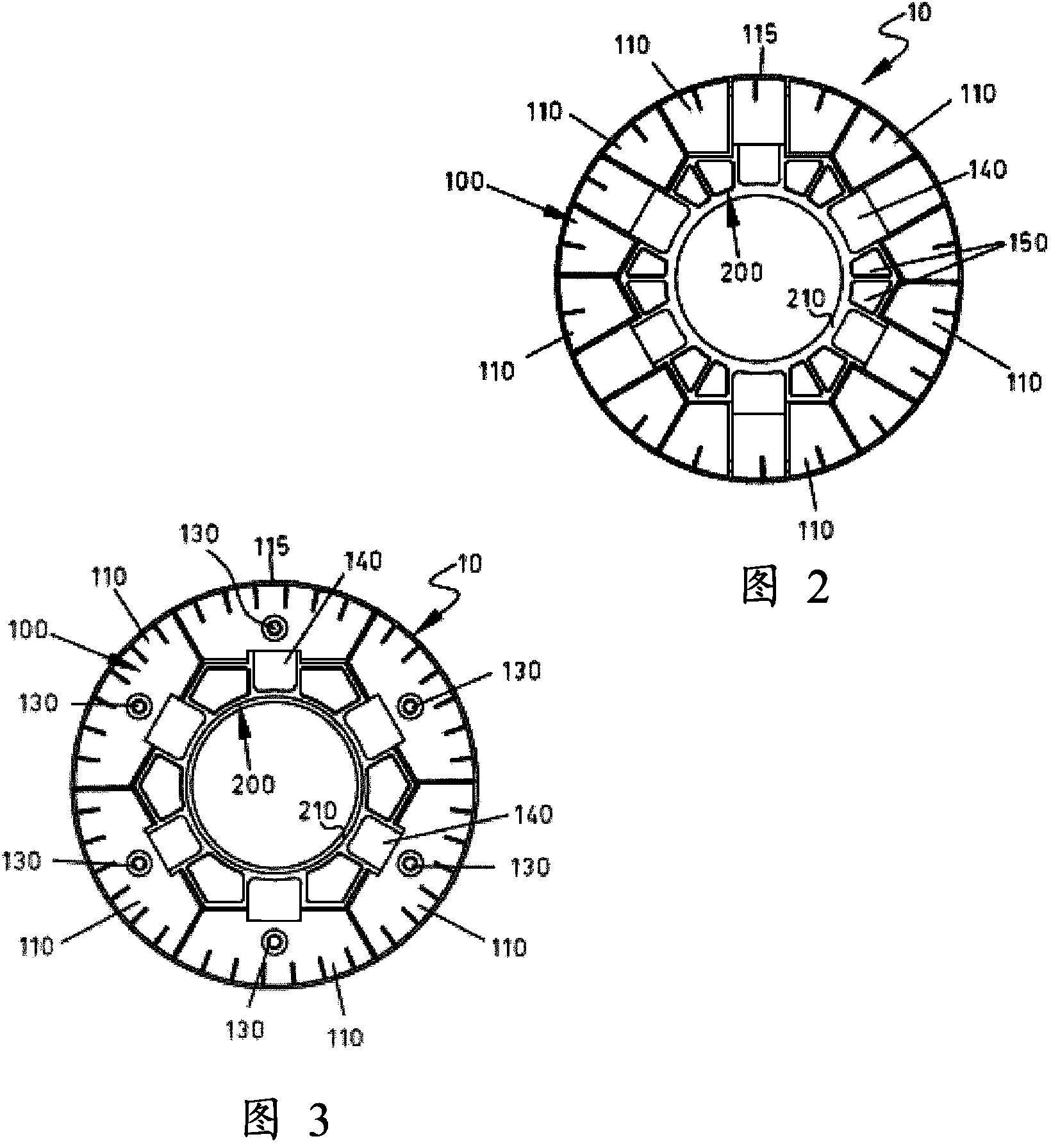

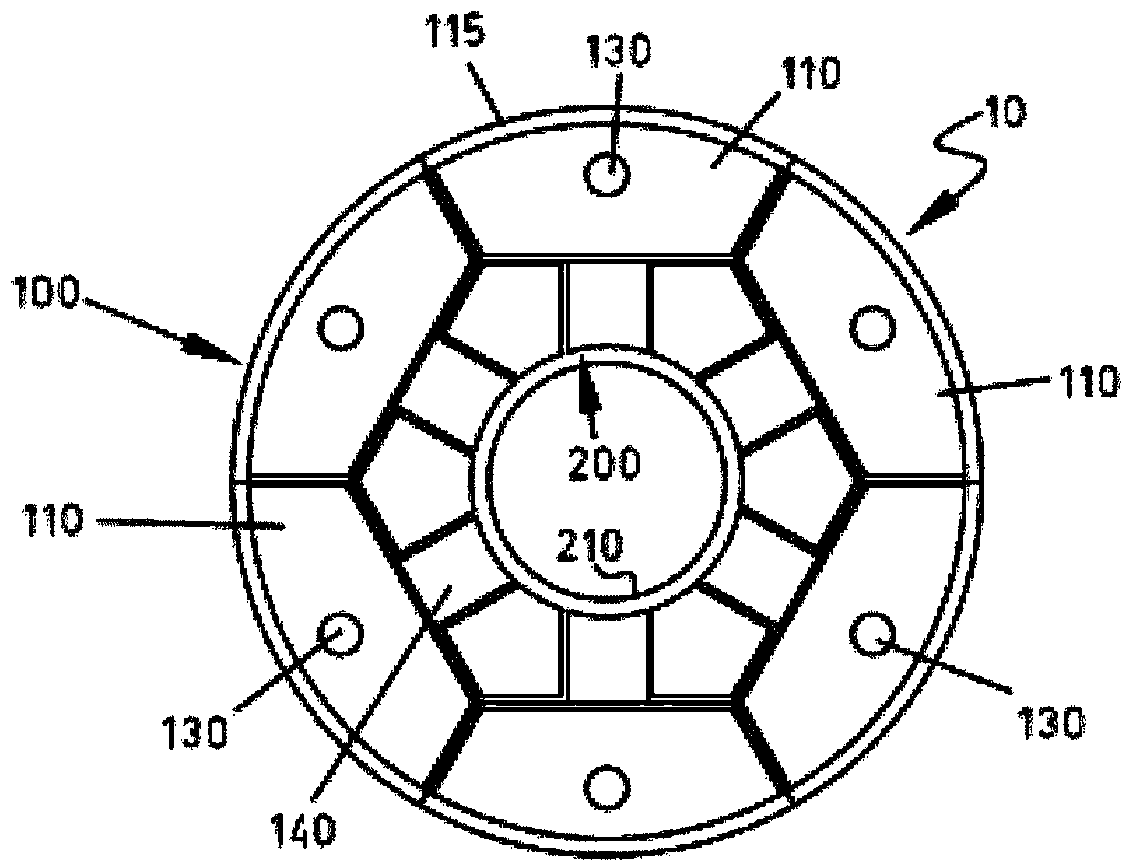

[0030] The figures show different embodiments of rotor assemblies suitable for direct synchronous wind turbine generators. The rotor assembly is generally indicated by the reference numeral 10 throughout the figures. In the respective drawings, the same reference numerals denote the same parts.

[0031] Such as Figure 7 and Figure 8 As shown, the rotor assembly 10 is rotatable relative to the stator assembly 300 via suitable bearings 310 .

[0032] As a non-limiting example in Figure 1-5 The embodiment of the rotor assembly 10 shown in includes six rotor segments 110 . Other embodiments of the rotor assembly 10 may also have other different numbers of rotor segments 110 as desired. For example, Figure 6 The illustrated embodiment of the rotor assembly 10 includes four rotor segments 110 .

[0033] Such as Figure 1-6 As shown, rotor segments 110 form modular rotor structure 100 . Dividing the rotor structure 100 of the rotor assembly 10 into rotor segments 110 fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com