Electric heating low temperature cigarette

A low-temperature cigarette and electric heating technology, which is applied in tobacco, pipes, applications, etc., can solve the problems of affecting user experience and slow heating speed, and achieve the effect of good user experience, fast heating speed and fast smoke output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

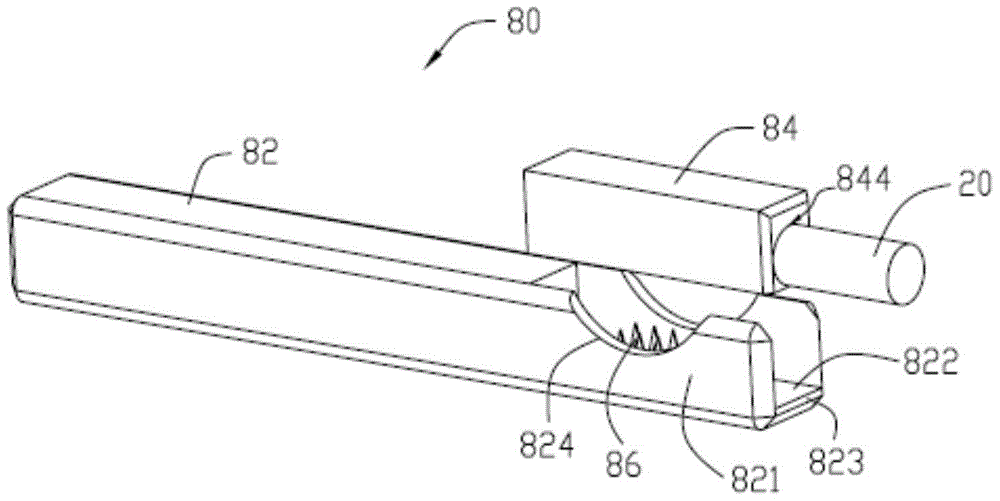

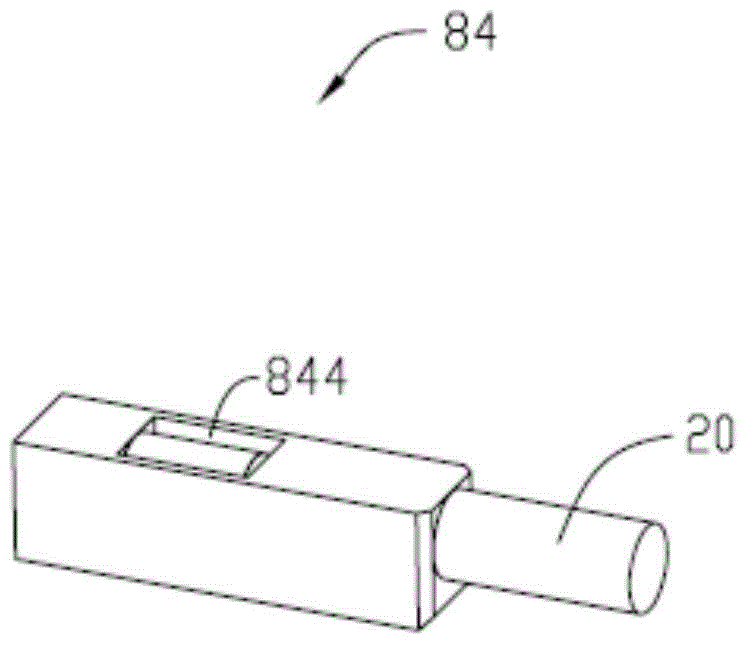

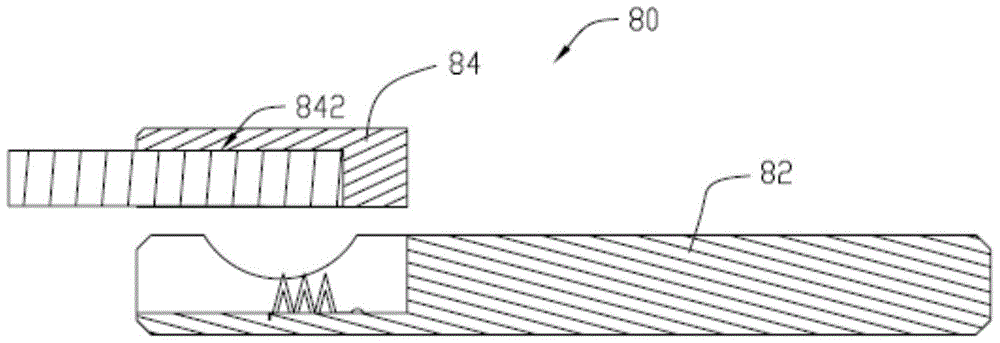

[0046] Such as Figure 1-5 As shown, an electrically heated low-temperature cigarette 80 includes a main body 82 , a cover 84 matched with the main body 82 , and a heating component 86 .

[0047] Electric heating low temperature cigarette 80 is suitable for baking such as Figure 6 The shown cigarette 20 is used to generate smoke. The cigarette 20 includes a connected body portion 22 and a filter tip 24. The body portion 22 is filled with solid smoking substances such as tobacco and shredded tobacco. The filter tip 24 is used to filter impurities in the smoke. Cigarette 20 can adopt special cigarette, also can use common cigarette.

[0048] The main body 82 is generally a long and narrow cuboid. One end of the main body 82 has two opposite side walls 821 and a bottom wall 823. The bottom wall 823 is connected between the two side walls 821. The two side walls 821 and the bottom wall 823 are in common A groove 822 matching the shape of the cover body 84 is formed. In this em...

no. 2 example

[0056] Such as Figure 8 As shown, the heat generating component 16 provided by the second embodiment of the present invention is similar to the heat generating component 86 provided by the first embodiment, the main difference is that: the heat generating component 16 includes a plurality of heat generating sheets 162, such as Figure 6 shown. Each heating piece 162 is in the shape of an inverted "V" and has a sharp point so as to penetrate into the cigarette 20 easily. In this embodiment, a plurality of heating sheets 162 are arranged in parallel, and two adjacent heating sheets 162 are connected in series through connecting parts 166, and electrical connecting parts 164 are respectively formed at both ends, and the electrical connecting parts 164 are used for connecting with power supply. The positive and negative poles of the device are electrically connected by means of welding or riveting. The heating component 16 can be integrally formed by stamping, and the material ...

no. 3 example

[0058] Such as Figure 9 As shown, the heat generating component 46 provided by the third embodiment of the present invention is similar to the heat generating component 86 provided by the first embodiment, the main difference is that: a transverse connecting portion 4624 is further connected between two adjacent heat generating elements 4622, so that the relative Adjacent heating elements 4622 are spaced apart by a certain distance. When installed, the heating component 46 is embedded in the main body 82, and the transverse connecting portion 4624 is located below the surface of the bottom wall 823. Refer to figure 1 . After the heating element 4622 is pierced into the cigarette, since adjacent heating elements 4622 are separated by a certain distance, the cigarette can be avoided from being pierced too much. After the heating element 46 comes out of the cigarette, the cigarette can maintain a relatively complete shape to facilitate cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com