Guide rail type cylinder bottom sludge discharge machine with vertically arranged transmission gear

A technology for installing guide rails and transmission devices, which is applied in the direction of cleaning hollow objects, cleaning methods and appliances, chemical instruments and methods, etc. It can solve the problems of inability to remove sludge, high equipment cost, and the position of the power reversing head, so as to solve the problem of decontamination Dead angle problem, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

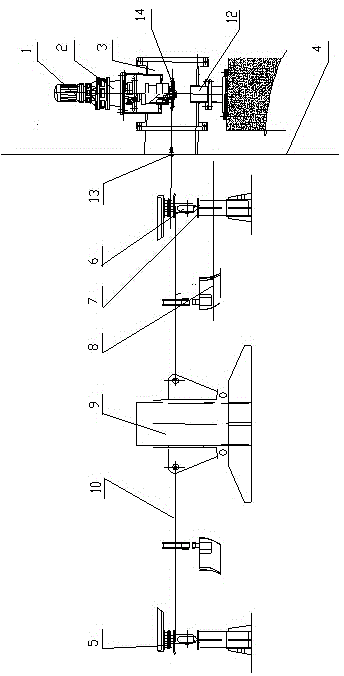

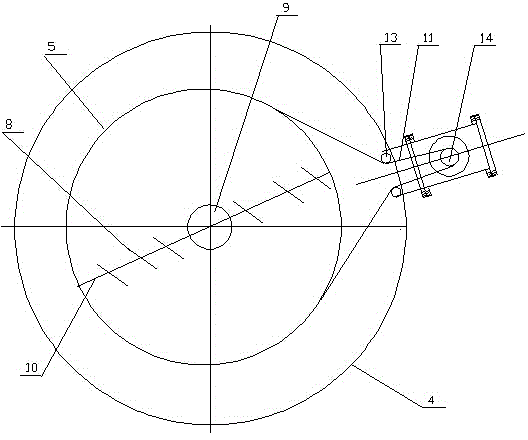

[0015] The transmission device is vertically installed guide rail type tank bottom mud discharger, including a motor 1, a reducer 2, a ring beam 5, a drag beam 10, a central shaft assembly 9 and a scraper head 8, the upper part of the reducer and the tee 3 Port connection, the inner horizontal port of the tee 3 is connected to the flange of the tank wall 4, the outer horizontal port of the tee 3 is closed, the tee 3 is fixed on the support 12, the reducer 2 passes through the working sprocket 14 and the chain 11 The tank wall flange is connected with the ring beam 5. A tensioner 11 is provided at the place where the connecting rod connecting the tee 3 and the ring beam 5 passes through the tank wall 4 . The said ring beam 5 is connected with the drag beam 10, the drag beam 10 bottom is provided with a scraper 8, one end of the drag beam 10 is fixed on the drum of the central shaft assembly 9, and the other end is connected with the ring beam 5. A scraping head is provided at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com