Temporary cross brace of a space cable suspension bridge and its hoisting construction method

A suspension bridge and cable technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as interfering with waterway traffic, achieve clear component stress, reduce construction risks, and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

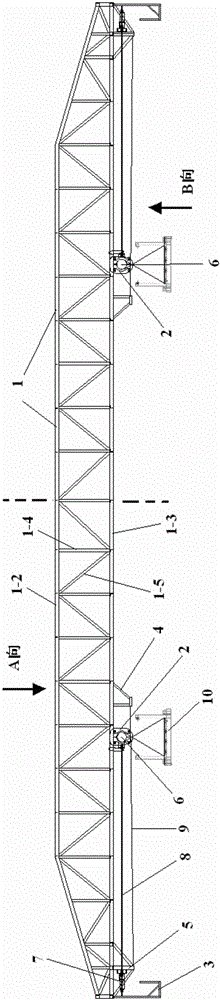

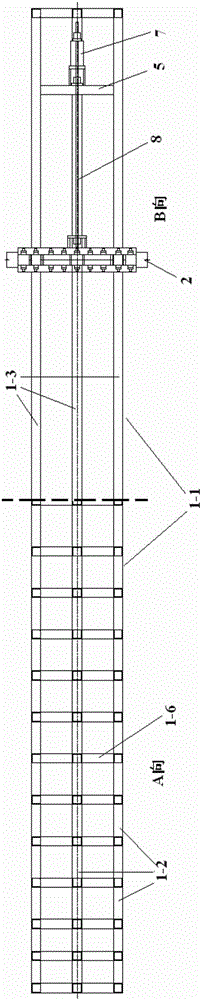

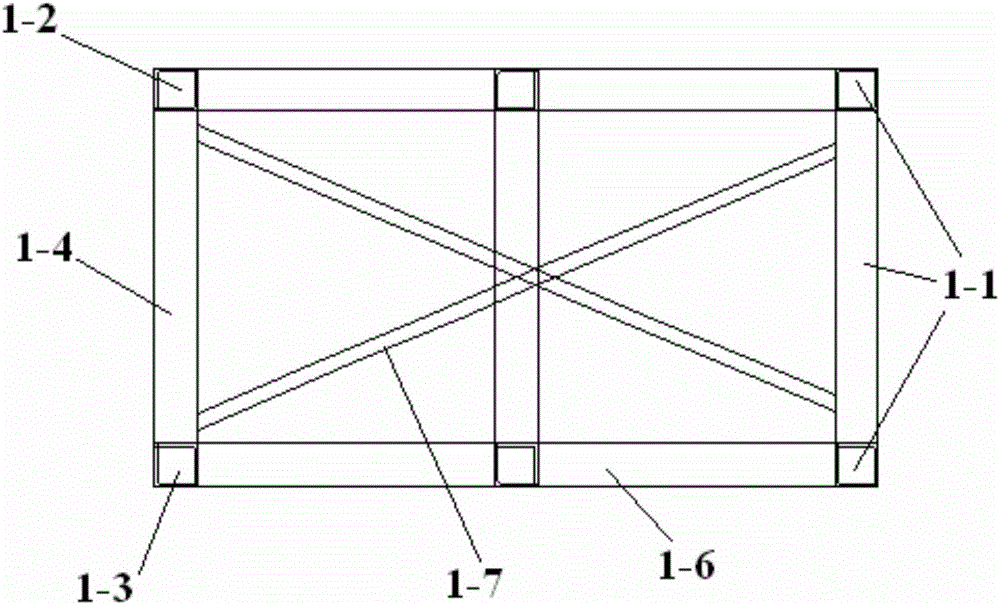

[0058] This embodiment provides a temporary cross brace for a space cable suspension bridge, including a cross beam 1 and a temporary cable clamp 2 for pulling and moving the main cable. It is characterized in that: the cross beam 1 includes three parallel trusses 1-1, each truss -1 includes the upper chord 1-2, the lower chord 1-3, the vertical bar 1-4 and the inclined bar 1-5, and the three trusses 1-1 are connected by the cross bar 1-6 and the side slanting bar 1-7. overall;

[0059] The two ends of the bottom of the beam 1 are respectively provided with an operating platform 3, and the bottom of the beam 1 between the two operating platforms 3 is symmetrically installed with two stop frames 4 and two counter force frames 5, and the two stop frames 4 are close to the center of the beam 1 The position is symmetrically installed at the bottom of the beam 1, and the distance between the two stop frames 4 is smaller than the distance between the two main cables 6 when the space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com