Backlight module and manufacturing method for same

The technology of a backlight module and its manufacturing method, which is applied in the directions of optics, light guides, light sources, etc., can solve the problems of easy light leakage and reduce the brightness of the backlight module, and achieve the effect of improving brightness and eliminating light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

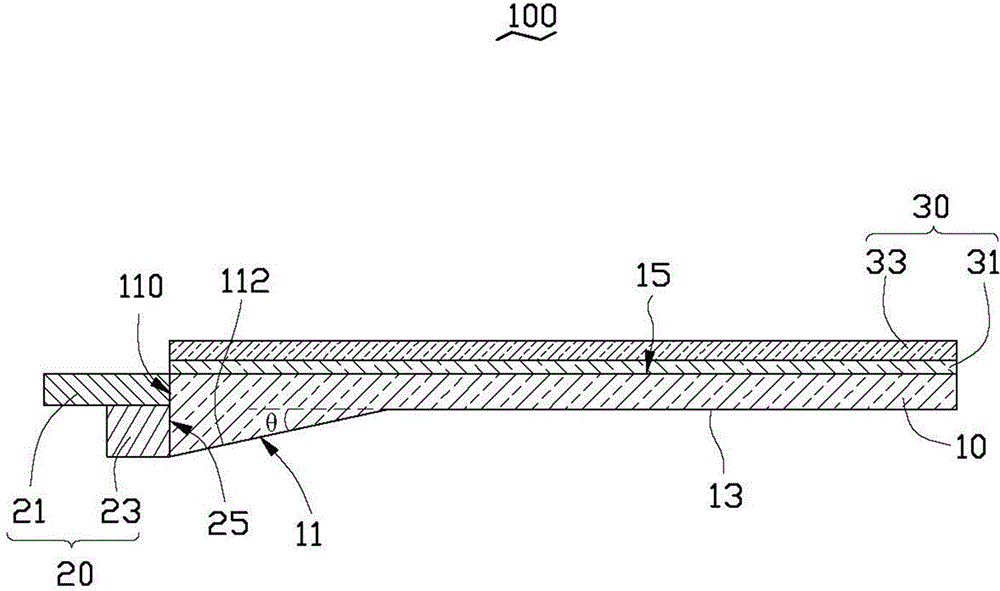

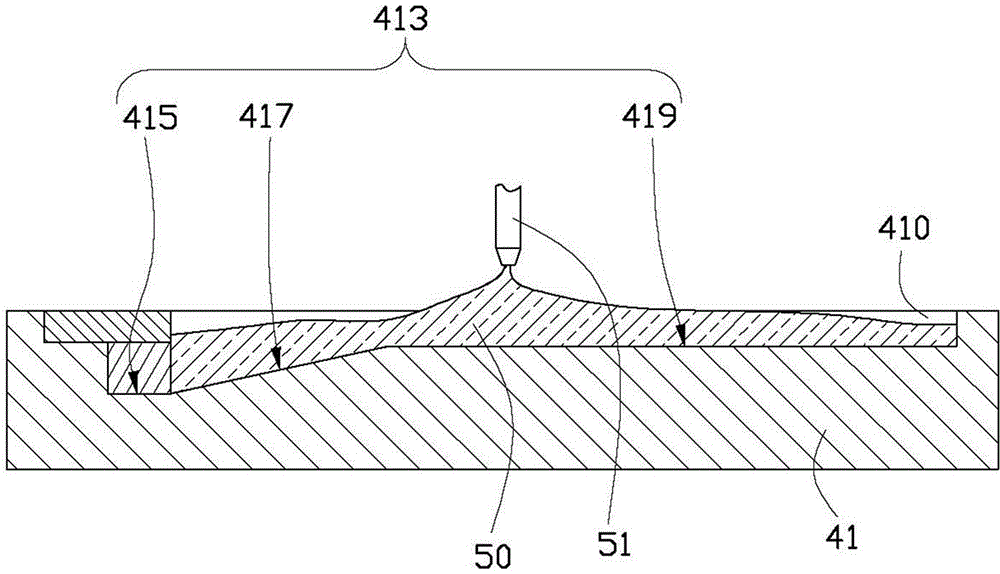

[0015] see figure 1 , figure 2 and Figure 5 , which discloses the backlight module 100 provided by the embodiment of the present invention.

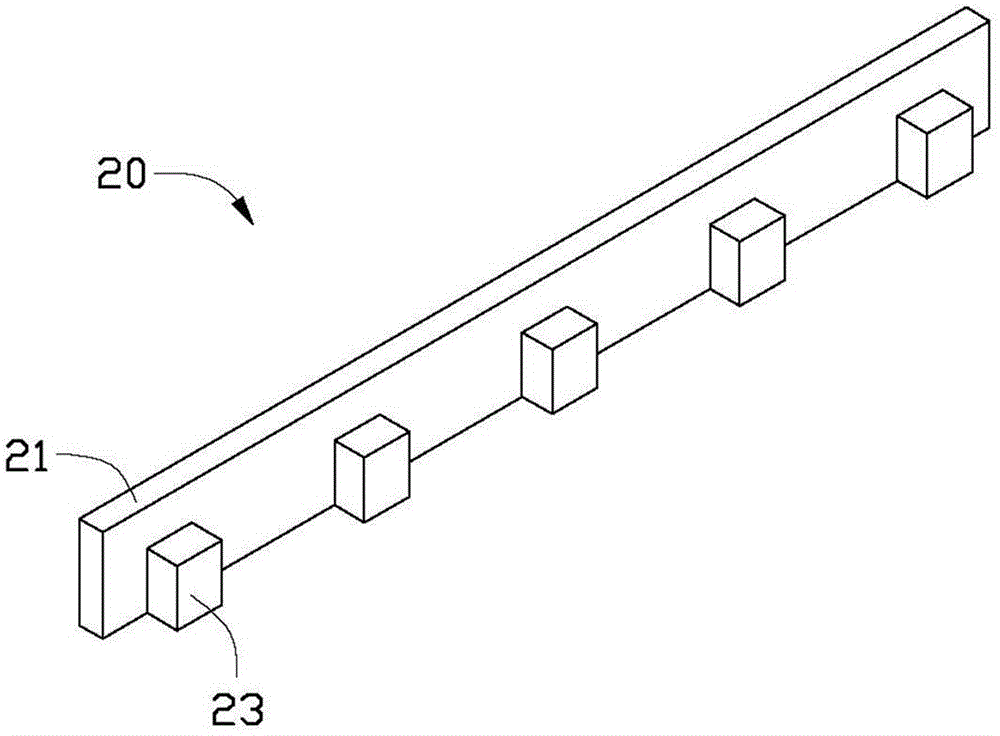

[0016] The backlight module 100 includes a light guide film 10 , a light bar 20 and an optical film set 30 . The light guide film 10 is made of ultraviolet curing glue or heat curing glue. The light guide film 10 includes a wedge portion 11 adjacent to the light bar 20 and a flat portion 13 adjacent to the wedge portion 11 . The wedge portion 11 and the flat portion 13 are integrally formed and have a common plane 15 , which is the light emitting surface of the light guide film 10 . The wedge-shaped portion 11 has a light incident surface 110, the light incident surface 110 is perpendicular to the plane 15, and the thickness of the wedge-shaped portion 11 gradually decreases from the light incident surface 110 to the flat plate portion 13 to the thickness of the flat plate portion 13, i.e. The flat plate portion 13 has a uniform t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com