Spectrum measuring fixture

A spectrum and fixture technology, applied in the field of spectrum measurement fixtures, can solve the problems of inability to accurately and effectively control product quality and performance, low accuracy, and light leakage from the edge of optical diaphragms, so as to eliminate inaccurate measurement or light leakage. phenomenon, improve measurement accuracy, and eliminate the effect of light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

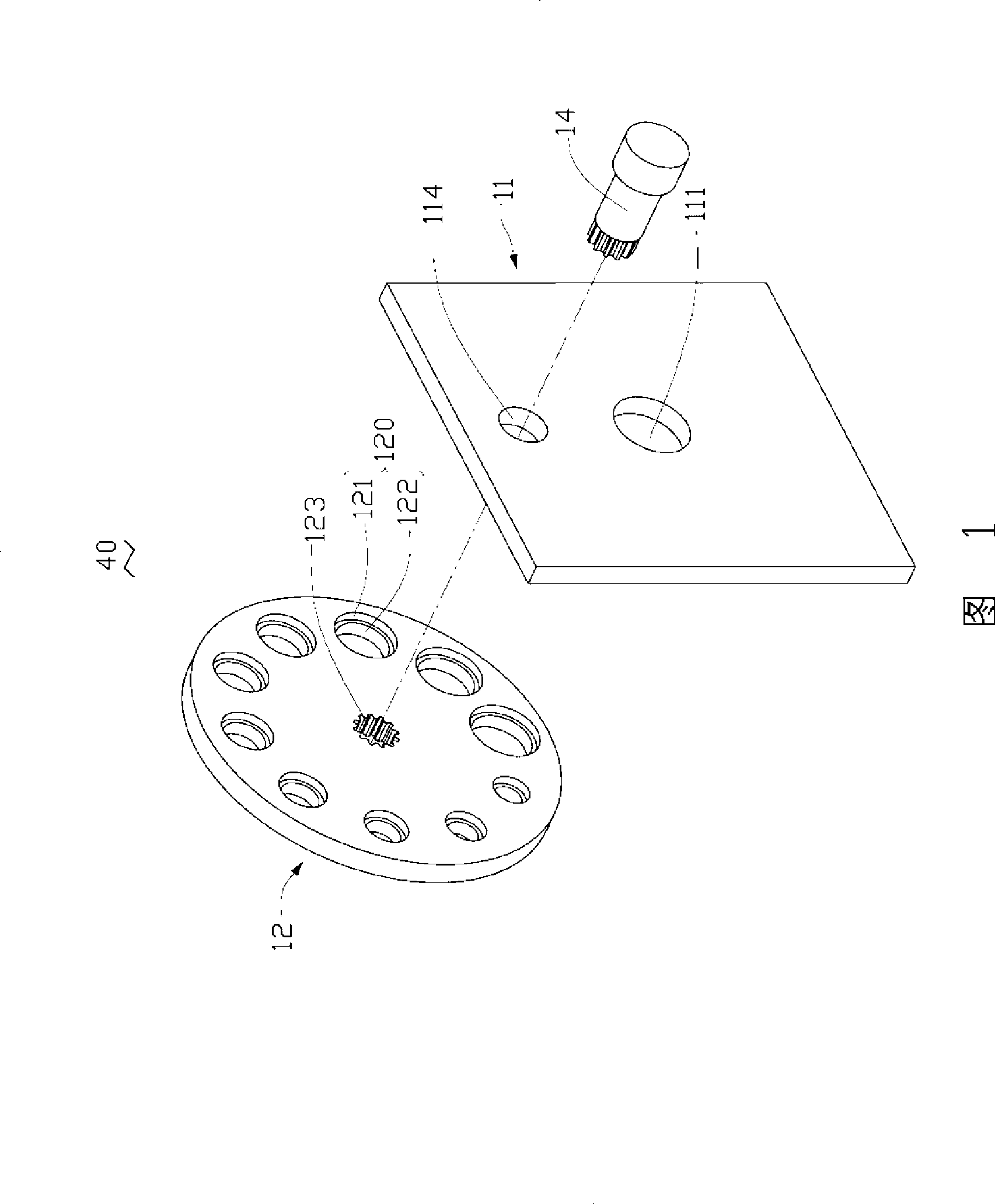

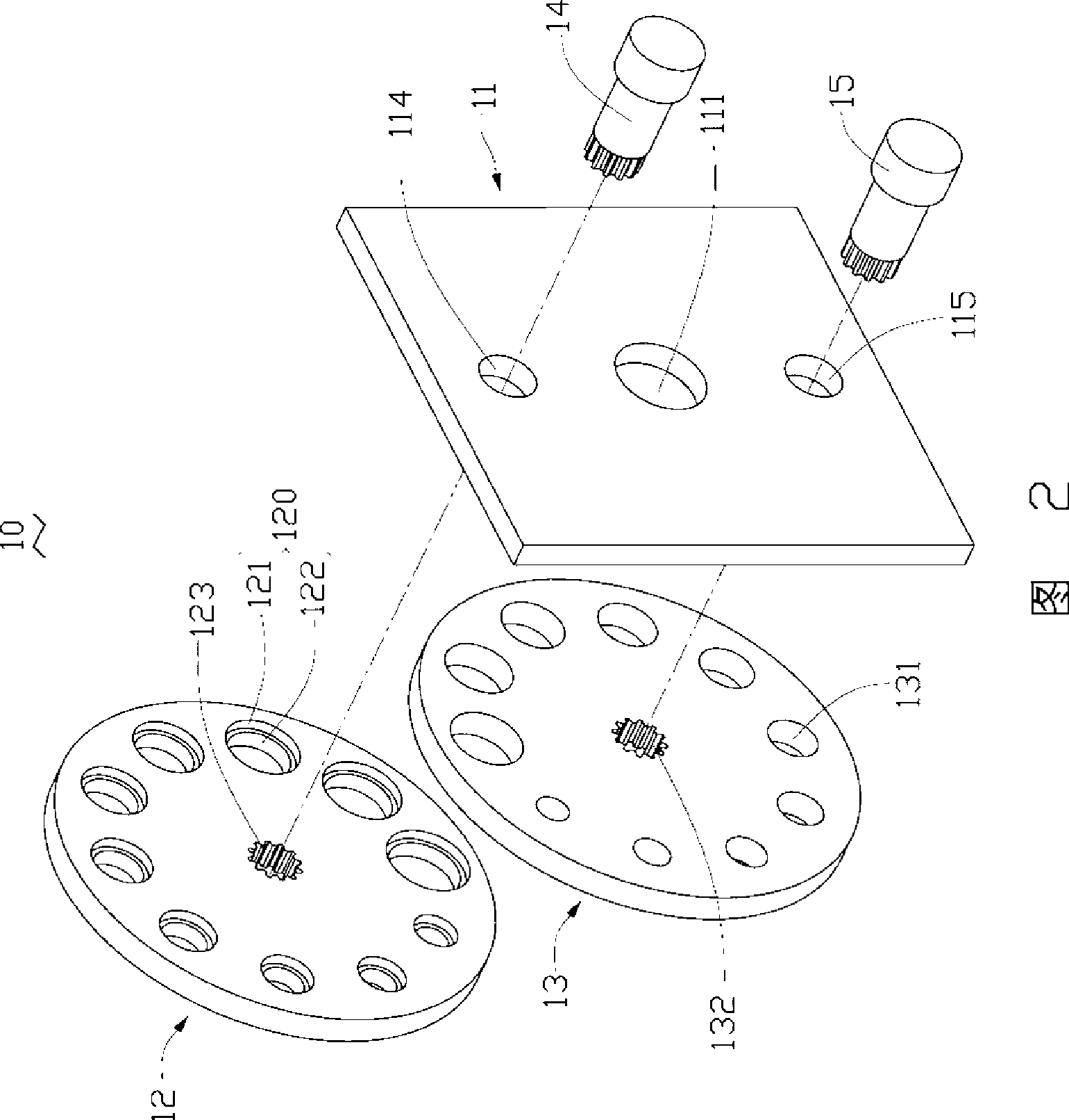

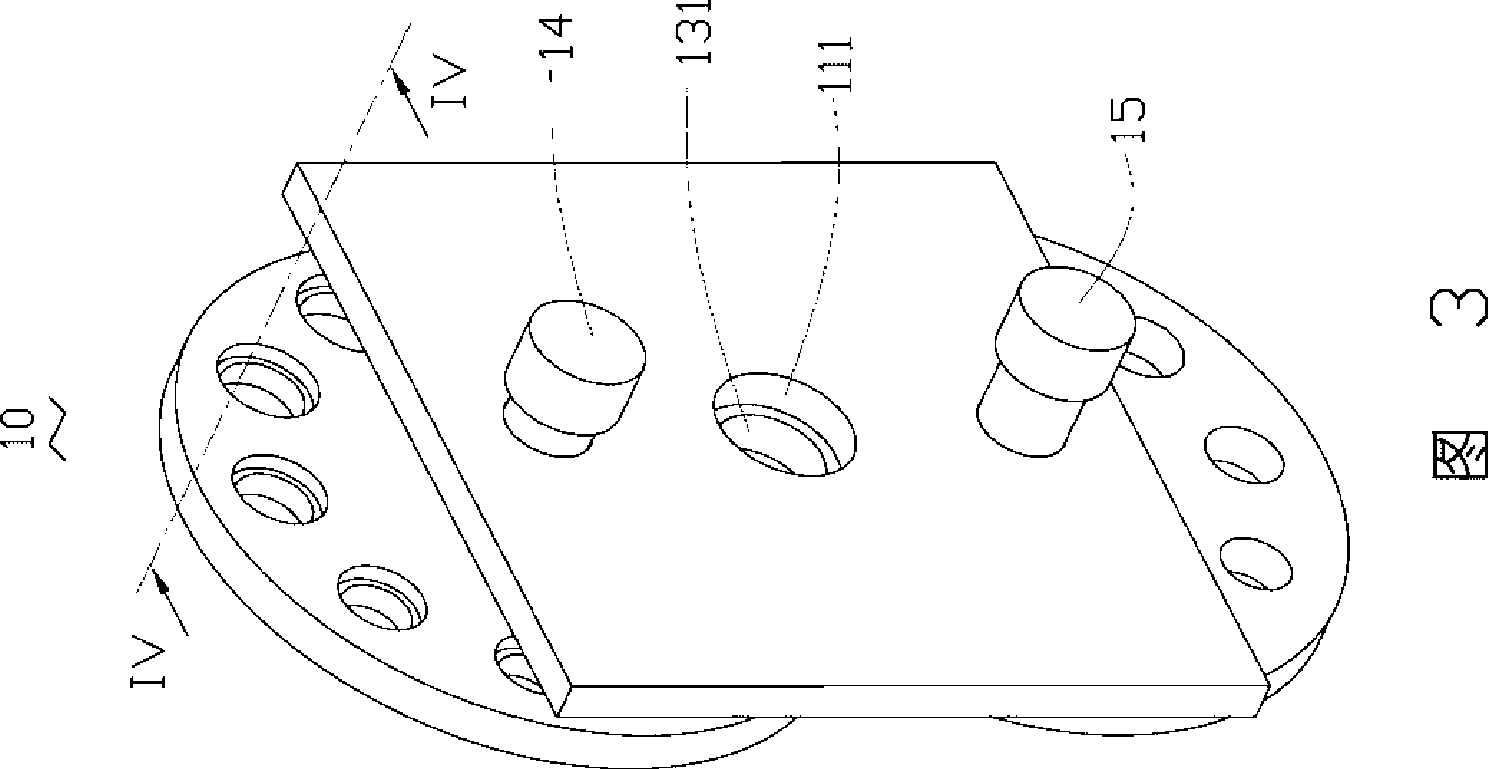

[0018] Please refer to FIG. 1 , the spectrum measuring fixture 40 according to the first embodiment of the present invention includes a fixing plate 11 and a circular placing plate 12 . The center of the fixing plate 11 has a first light-transmitting hole 111, and the circumference of the circular placement plate 12 has several circular receiving holes 120 with different diameters, and each of the receiving holes 120 has a receiving hole 120. part 121 and a second light transmission hole 122 located at the bottom center of the receiving hole 120, and the diameter of the second light transmission hole 122 is slightly smaller than the diameter of the receiving part 121, and the plurality of receiving holes 120 reach the circular position The center of circle distance of putting plate 12 is identical.

[0019] The spectrum measurement fixture 40 further include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com