A sample preparation device for triaxial compression test of remolded soil

A technology of triaxial compression and sample preparation, which is applied in the preparation of test samples, etc., can solve the problems of cumbersome sample disassembly, looseness in the middle, large sample preparation errors, etc., meet the production accuracy requirements, and solve the exhaust problem , The effect of making the sample flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

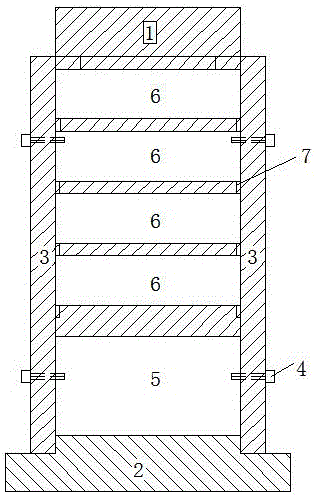

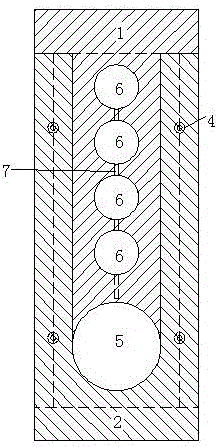

[0015] like figure 1 , 2 A remolded soil triaxial compression test sample preparation device shown in the figure includes an upper pressing plate 1, a base 2, a horizontal plate 3, an exhaust hole 7, and an exhaust groove 6. The plate 3 forms the sample preparation chamber 5 ; the upper platen 1 is provided with a number of exhaust grooves 6 , and there are exhaust holes 7 between the exhaust grooves 6 .

[0016] Further, the horizontal plate 3 and the base 2 are connected by fixing the horizontal plate nut 4 to enclose a rectangular empty box.

[0017] Further, the sample preparation chamber 5 is cylindrical, the exhaust groove 6 is cylindrical, and the exhaust holes 7 are located on the upper pressing plate 1 at both ends of the exhaust groove 6 .

[0018] The steps of preparing the test sample by the remolded soil triaxial compression test sample preparation device are as follows: according to the designed dry density and moisture content of the reshaped soil, weigh the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com