Electromagnetic relay coil support and manufacture method thereof

A technology of electromagnetic relay and manufacturing method, which is applied in the direction of relays, circuits, electrical components, etc., can solve the problems of low dimensional accuracy of coil terminals, skewed relay finished pins, and core 221 skews, etc., to solve coil pin skews, dimensions The effect of stable and effective positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

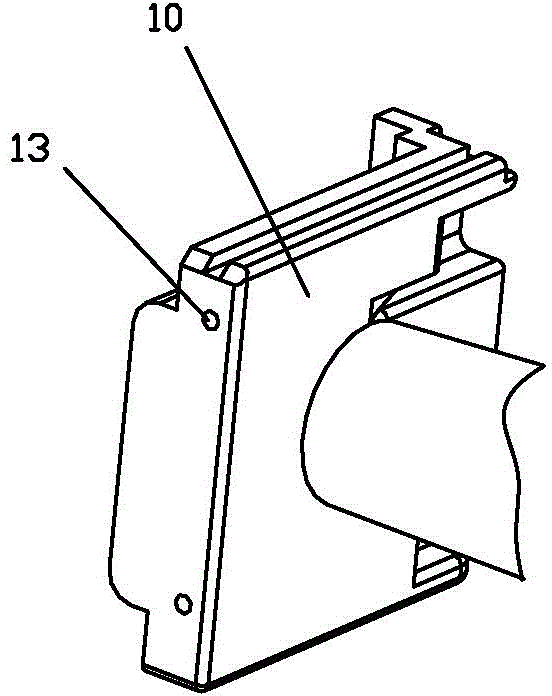

[0048] see Figure 11 to Figure 18 As shown, an electromagnetic relay bobbin of the present invention includes a bobbin body 30, and a terminal hole 3 for installing a coil terminal is provided in the bobbin body, and the terminal hole 3 is a semi-blind hole structure.

[0049] The semi-blind hole structure is composed of a cylindrical main hole 31, a cylindrical surface entity 32 and four side holes 33. The surface entity 32 has the same diameter as the main hole 31, and the surface entity 32 is connected to the main hole. One end of hole 31 is to close this end opening of main hole, and described four side holes 33 surround the periphery of described surface layer entity 32 and contact with the periphery of described surface layer entity 32, and one end of side hole 33 communicates with the outside, The other end of the side hole 33 is in contact with the periphery of the main hole 31 so that the side hole 33 communicates with the main hole 31 .

[0050] The four side holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com