Radio frequency coaxial cable connector and processing and assembling process thereof

A technology of radio frequency coaxial cable and assembly process, which is applied in the direction of two-part connection device, connection, assembly/disassembly of contact pieces, etc., can solve the problems of numerous processing procedures, difficulty in machining, high production cost, etc., and achieve reduction of processing procedures and The waste of materials, the satisfaction of mechanical and electrical properties, and the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

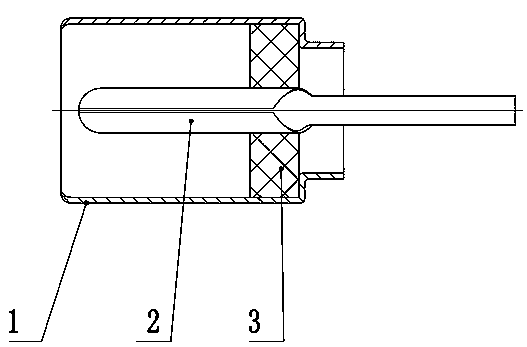

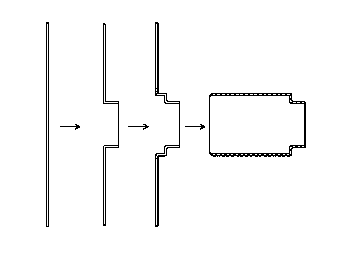

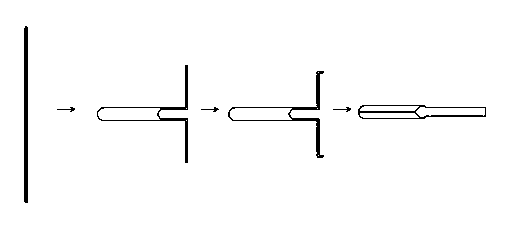

[0023] Such as Figure 1 to Figure 4 As shown, the technical solution adopted by the present invention is as follows: a radio frequency coaxial cable connector, comprising an outer conductor 1, an inner conductor 2 and an insulator 3, wherein the outer conductor 1 is of a cylindrical structure, and the central through hole is provided with There is a stepped ring surface; the above-mentioned insulator 3 is installed in the central through hole of the above-mentioned outer conductor 1, and is attached to the stepped ring surface in the through-hole of the outer conductor 1, and a through hole is provided in the middle of the insulator 3; the above-mentioned inner conductor 2 passes through the insulator 3 through holes in the middle, and extend into the central through hole of the outer conductor 1.

[0024] The outer conductor 1 is made of copper material, and the outer co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com