Motor vehicle horn long-time sounding protection method and circuit

A technology for protecting circuits and motor vehicles, applied in transducer circuits, electrical components, vehicle parts, etc., can solve the problems of burnt contacts of horns, damage to horns, and the time for each horn to sound more than 3-4 minutes, so as to achieve protection Effects of overheating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

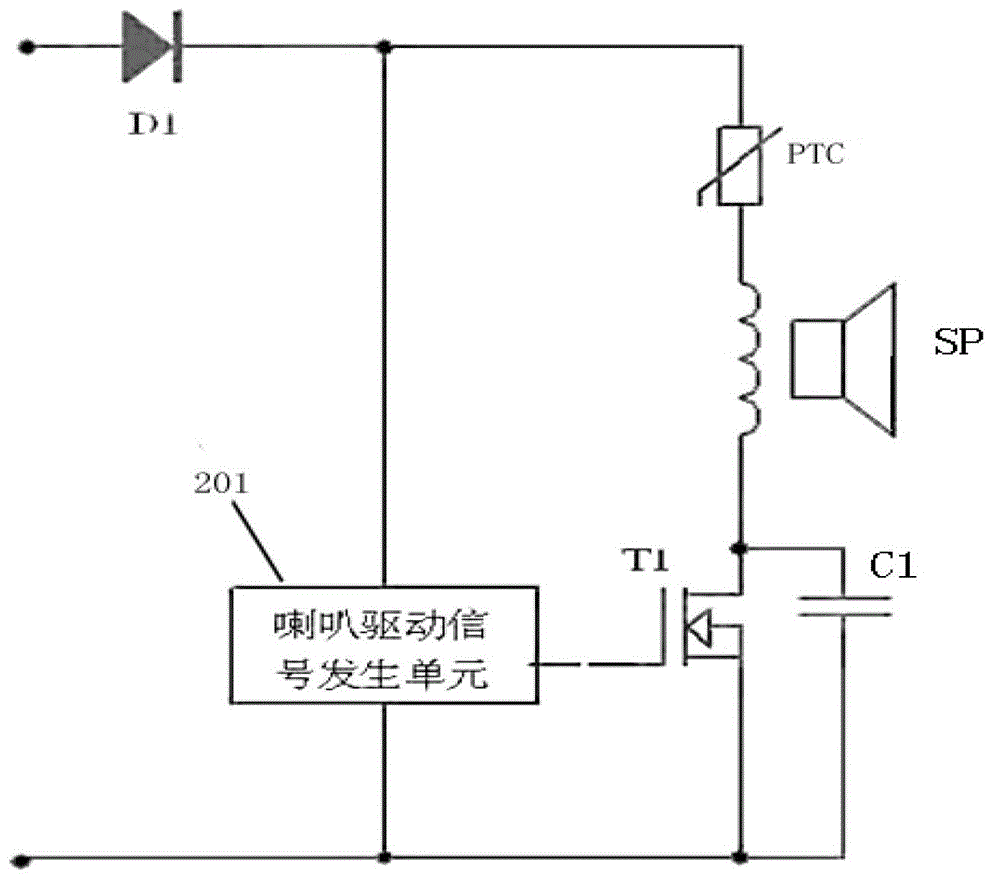

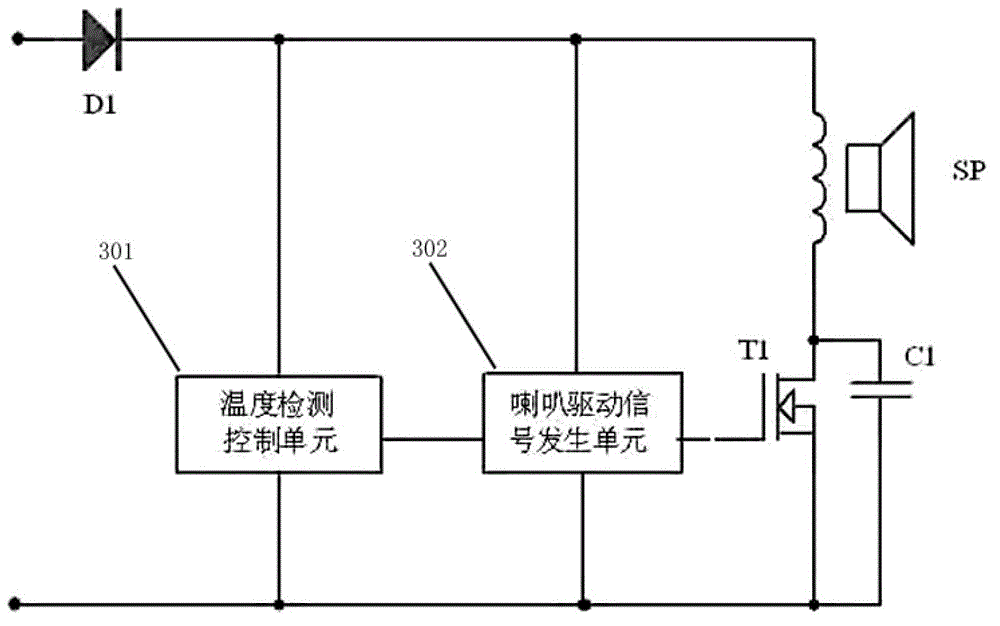

[0018] An embodiment of the present invention provides a motor vehicle horn beeping protection circuit for a long time. The protection circuit includes a horn coil, and is characterized in that it also includes: a temperature detection unit for detecting the temperature of the horn coil when the motor vehicle horn is working or a temperature close to it; a control unit for detecting the temperature of the horn coil when the motor vehicle horn is working When the coil temperature increases, reduce the horn drive current.

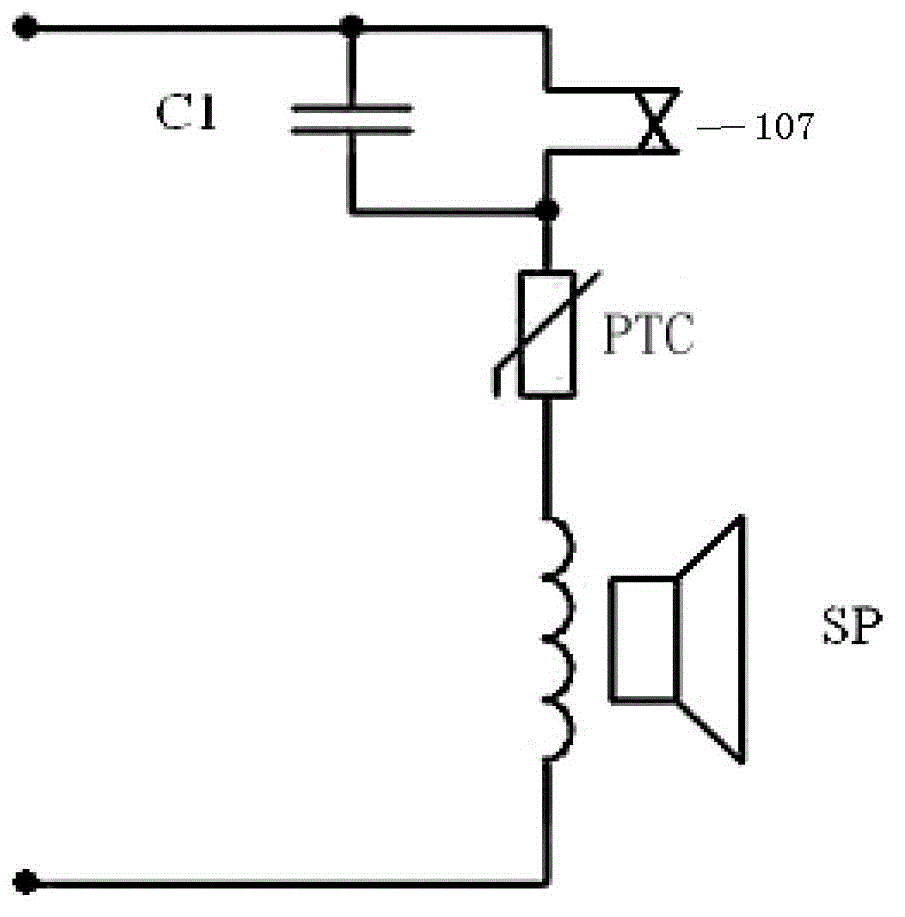

[0019] figure 1 A protection circuit diagram for a motor vehicle horn sounding for a long time provided by the embodiment of the present invention. Such as figure 1 As shown, the protection circuit includes a horn coil and a positive temperature coefficient power thermistor PTC element.

[0020] The power thermistor PTC element with a positive temperature coefficient can be used as a detection and control unit, and is connected in series between the speake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com