Apparatus and process for forming absorbent cores for absorbent sanitary products

An absorbent core, superabsorbent technology, used in the production of absorbent hygiene products, can solve the problems of difficult, considerable structural complexity, changing the concentration of superabsorbent polymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

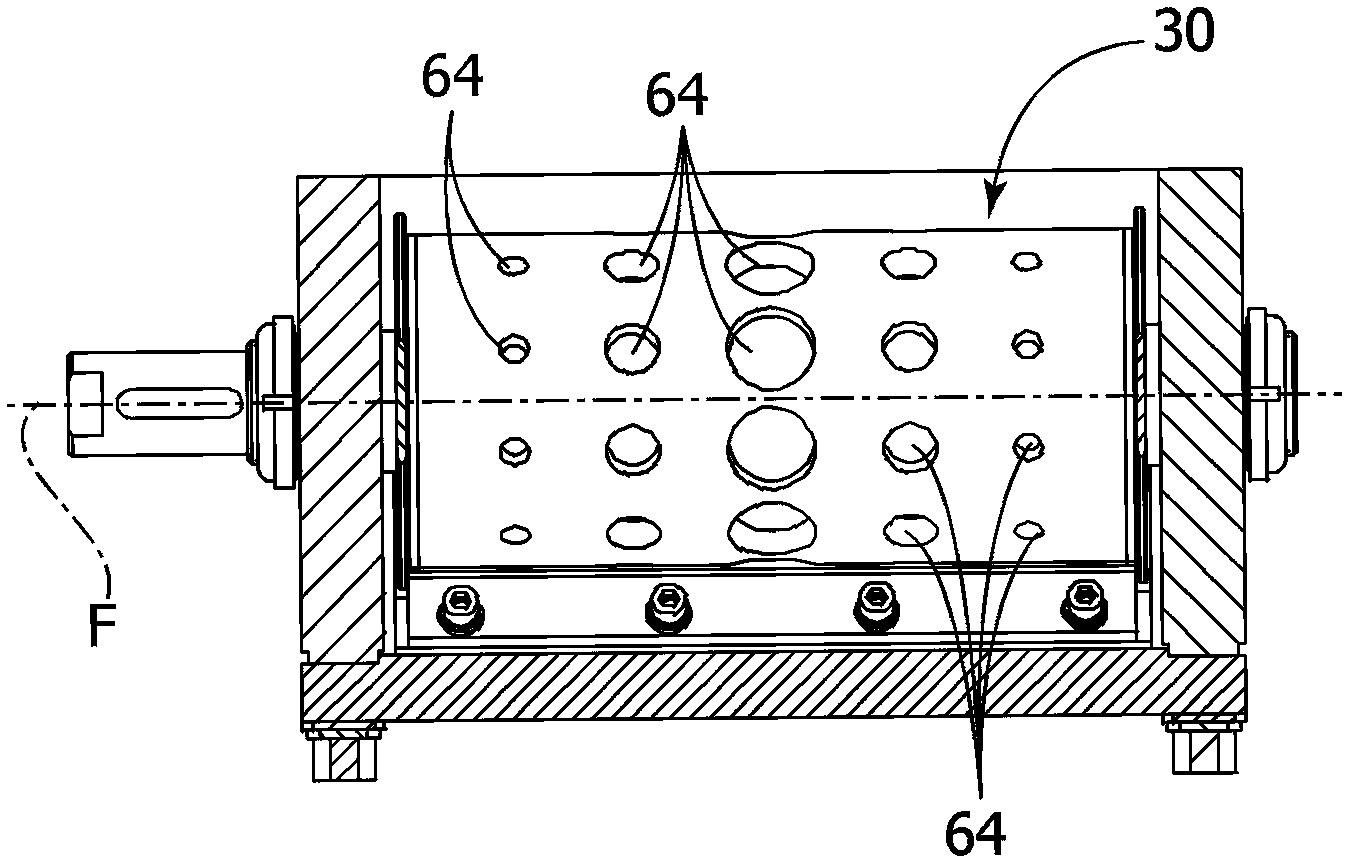

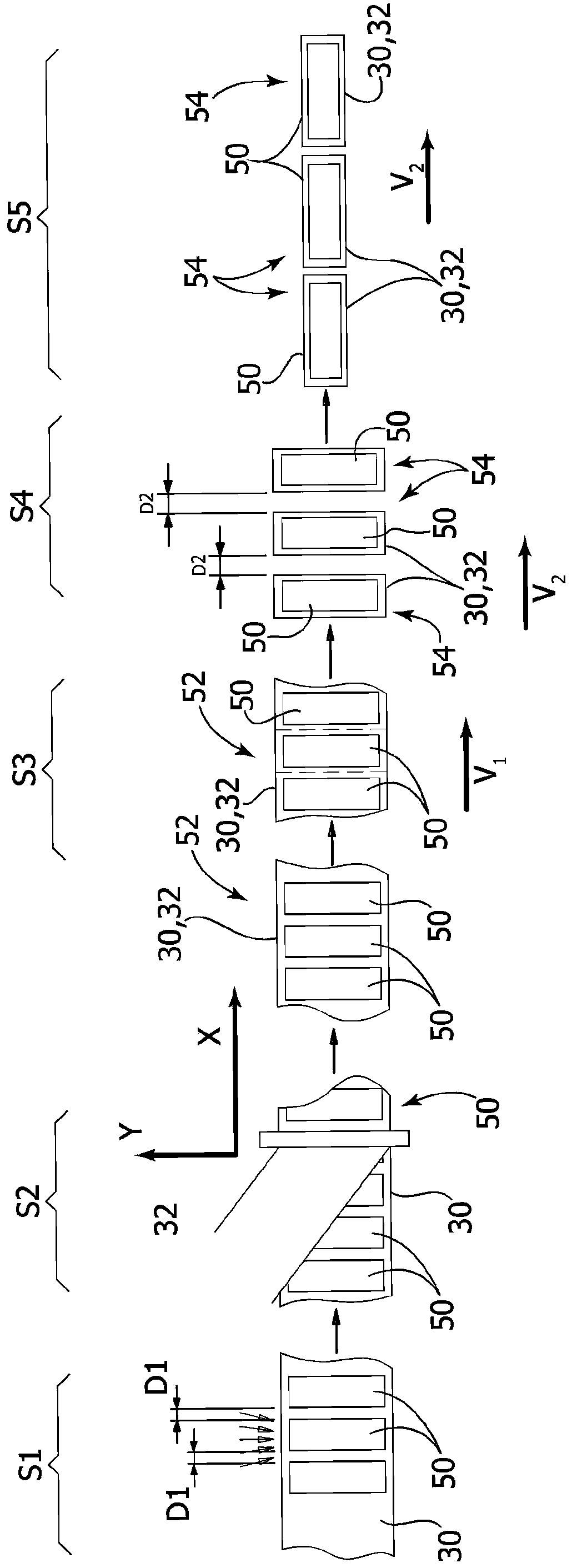

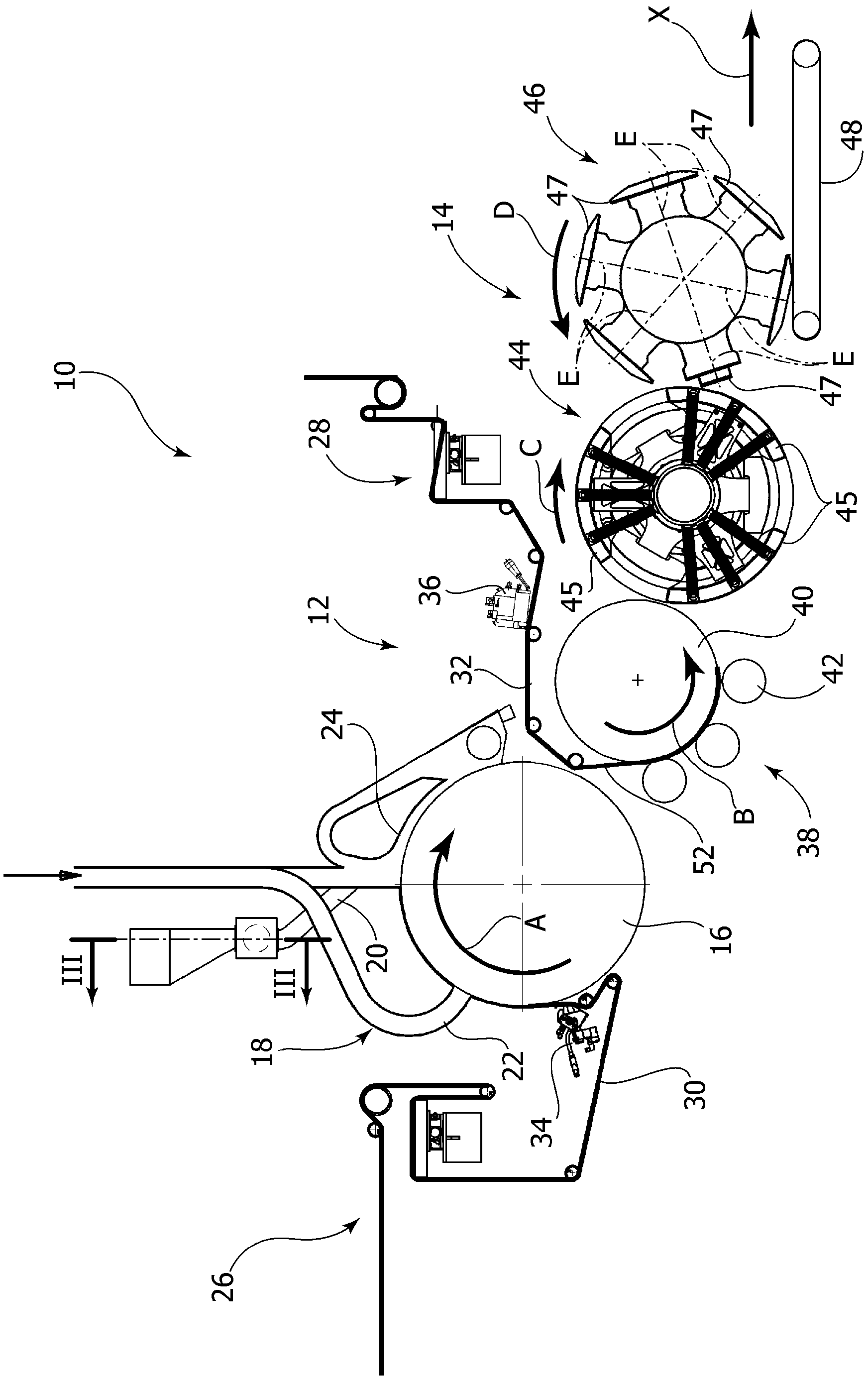

[0013] refer to figure 1 , designated by 10 is an apparatus for producing absorbent cores, forming part of a production line for producing absorbent hygiene articles. The apparatus 10 comprises a forming section 12 in which the absorbent core is formed and an application station 14 in which the absorbent core from section 12 is applied to a continuous support web moving in the longitudinal direction X. The forming section 12 comprises a forming wheel 16 rotatable in the direction shown by arrow A about a transverse axis orthogonal to the longitudinal direction X. As shown in FIG. The forming wheel 16 is provided on its periphery with holes connected to a suction source.

[0014] The forming section 12 includes a first conduit 18 for supplying cellulose fleece to the forming wheel 16 and a second conduit 20 for supplying a dispensed amount of superabsorbent polymer. The first duct 18 has an end 22 facing towards the periphery forming the wheel 16 . The second duct 20 compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com