A seedling harvesting type potato seedling killer

A potato and rack technology, applied in harvesters, digging harvesters, topping machines, etc., can solve the problems that the seedling machine cannot work well, and the separation of potato tubers and stalks is labor-consuming and time-consuming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

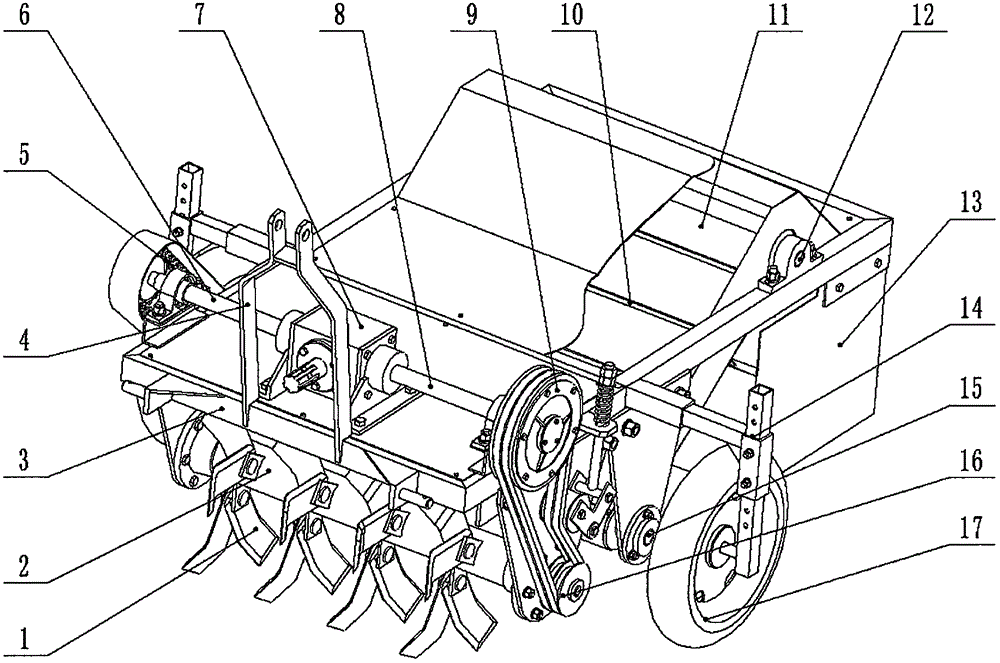

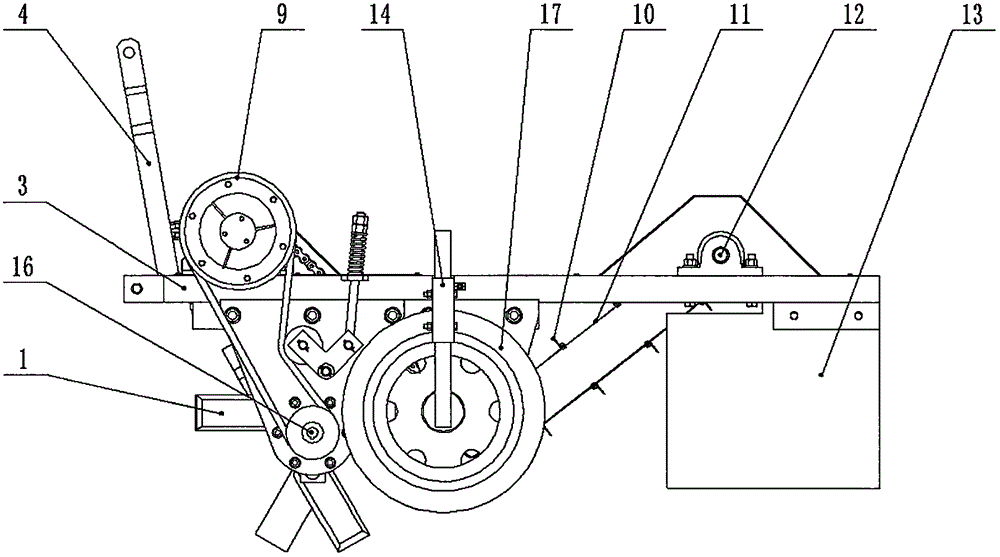

[0015] Such as figure 1 , figure 2 As shown, a harvesting type potato seedling killing machine includes a seedling killing knife 1, a knife shaft 2, a frame 3, a suspension frame 4, a chain drive 5, a left power output shaft 6, a gear box 7, and a right power output shaft 8 , large pulley 10, guard cover 11, seedling receiving box 14, regulating arm 15, small pulley 17, traveling wheel 18 and conveying mechanism. The conveyor belt scraper 10 is fixed on the conveyor belt 12 by a nut, and the conveyor belt 12 is installed on the rear bottom of the frame 3 through the conveyor belt driven shaft 13 and the conveyor belt driving shaft 14 . Frame 3 front bottoms are provided with a cutter shaft 2, and small belt pulley 17 is installed on its right-hand side, and seedling killing knife 1 takes two side by side, and the whole is spiral mode and is installed on the cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com