Straight-pulling rotary-cutting feeding type banana straw smashing, throwing and returning machine

A banana straw, feeding technology, applied in cutting equipment, agricultural machinery and implements, agriculture, etc., can solve the problems of high fiber toughness, low crushing efficiency, easy entanglement of banana straw fibers, etc. Effectiveness and efficiency, the effect of evenly spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

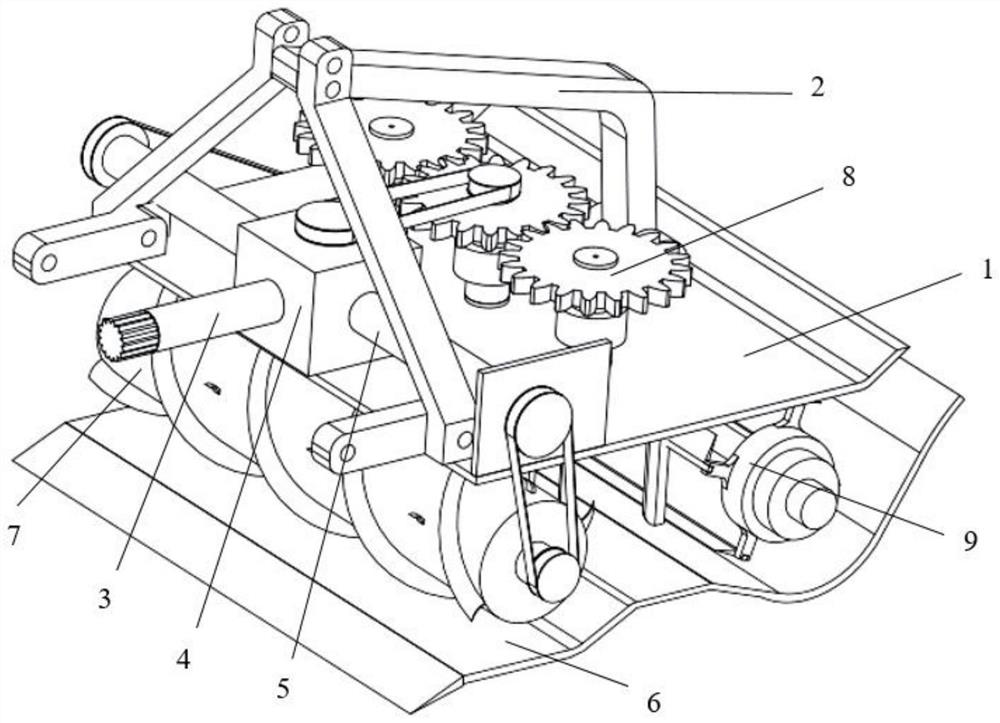

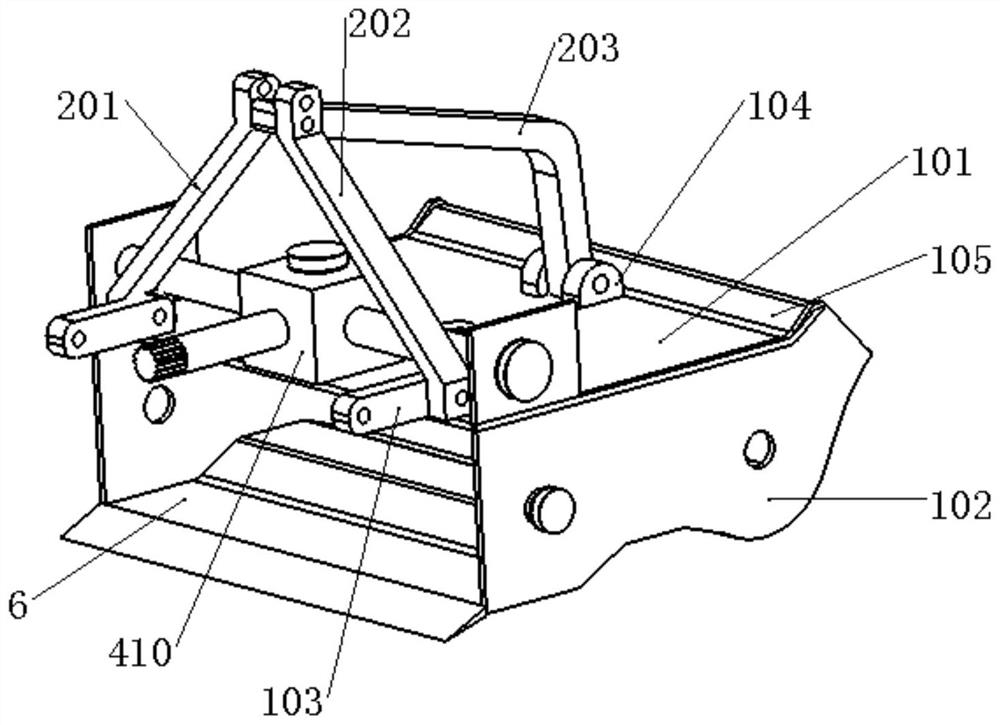

[0030] like figure 1 In the embodiment of the present invention shown, the machine tool is composed of a frame 1, a three-point suspension device 2, a power input shaft 3, a transmission device 5, a straight-pull rotary cutter horizontally provided with a straight-pull rotary cutter shaft 7, and a straight-pull rotary cutter. The vertical shaft cutting device with three pairs of vertical shaft cutting bodies 8 installed side by side behind the cutting device and the horizontal shaft meshing and throwing knife shaft 9 behind the vertical shaft cutting device are composed of the tractor power through the transmission device 5 respectively. The shaft 7, the vertical shaft opposite the cutting body 8 and the horizontal shaft are engaged with the cutting and throwing knife shaft 9. The fed banana straws are first driven by the straight-pulling rotary cutting knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com