Slag structure of a household oil press

An oil press and slag crushing technology, which is applied to presses, manufacturing tools, etc., can solve the problems of complex anti-swing structure, high production cost, motor locking, etc., to increase structural design and material cost, save material cost, Avoid wobble effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

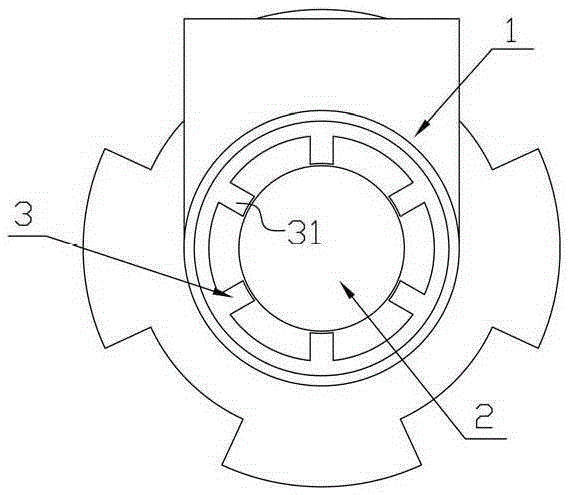

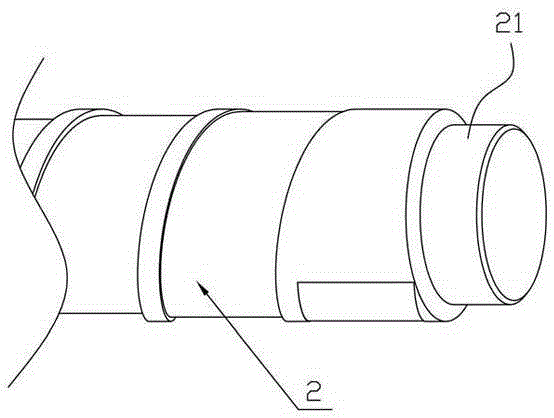

[0022] refer to figure 1 The broken residue structure of a household oil press is shown, and the broken residue structure is used in a screw extrusion type oil press. The oil press includes a pressing chamber 1 and a screw 2, and the screw 2 is coaxially installed in the pressing chamber within 1.

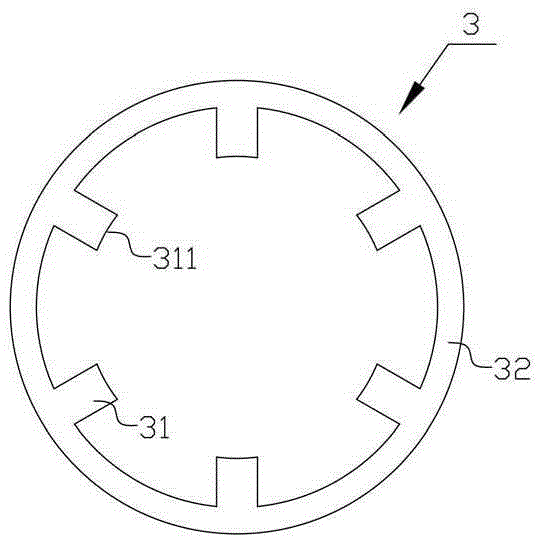

[0023] The tail end of the press chamber 1 is fixed with a slag scraper 3, which includes a number of protruding teeth 31 distributed around the circumference and facing the center of the circle. The diameter of the circle surrounded by the tops 311 of each protruding tooth 31 is smaller than the diameter of the inner wall of the press chamber 1 . Certainly, the slag scraping member 3 can be fixed on the inner wall of the tail end of the press chamber 1, or can be fixed on the outer end surface of the tail end of the press chamber 1 or other fixing methods, and the form is not limited. The shapes of the slag scraping member 3 and its protruding teeth 31 are not limited, as long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com