100% low-floor tramcar trailer body and assembling method thereof

A tram and low-floor technology, applied in the direction of railway car body, railway car body parts, transportation and packaging, etc., can solve the problems of high capital investment, complicated welding process and quality control process, and achieve weight reduction and convenient module Effects of modernized design and construction, green and environmental protection design concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

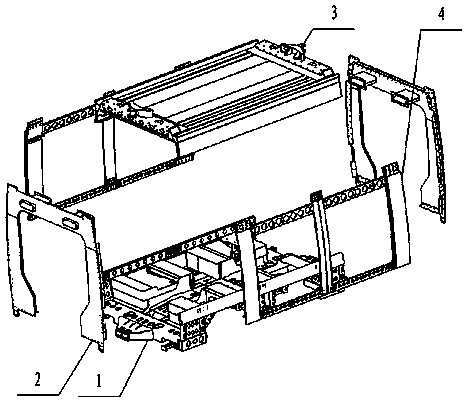

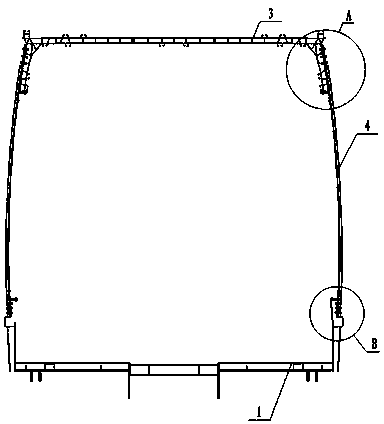

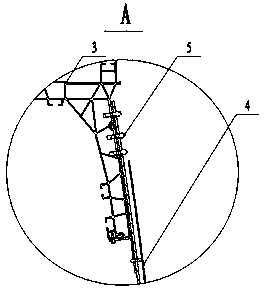

[0026] A 100% low-floor tram car body is a mixed steel-aluminum riveted car body, including a trailer, including 1 chassis, 2 end walls, 3 roofs, and 4 side walls. It has a simple structure, light weight, and convenient assembly in different places. Reliable performance and strong repairability. The four modules 1 underframe, 2 end walls, 3 roof and 4 side walls are riveted to form a frame structure, the overall strength and rigidity of the car body are guaranteed and the process difficulty of car body assembly is reduced; when one of the modules is damaged , this part can be replaced separately; the off-site factory can easily realize the separate transportation of the four modules, and the off-site quick integration reduces transportation costs and improves work efficiency.

[0027] Below i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com