Preparation method of dimethyl phthalate (DMP)

A technology of dimethyl phthalate and methanol, which is applied in the field of organic compound preparation, can solve problems such as waste of raw materials, high production costs, and incomplete reactions, and achieve the effects of good product quality, reduced energy consumption, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

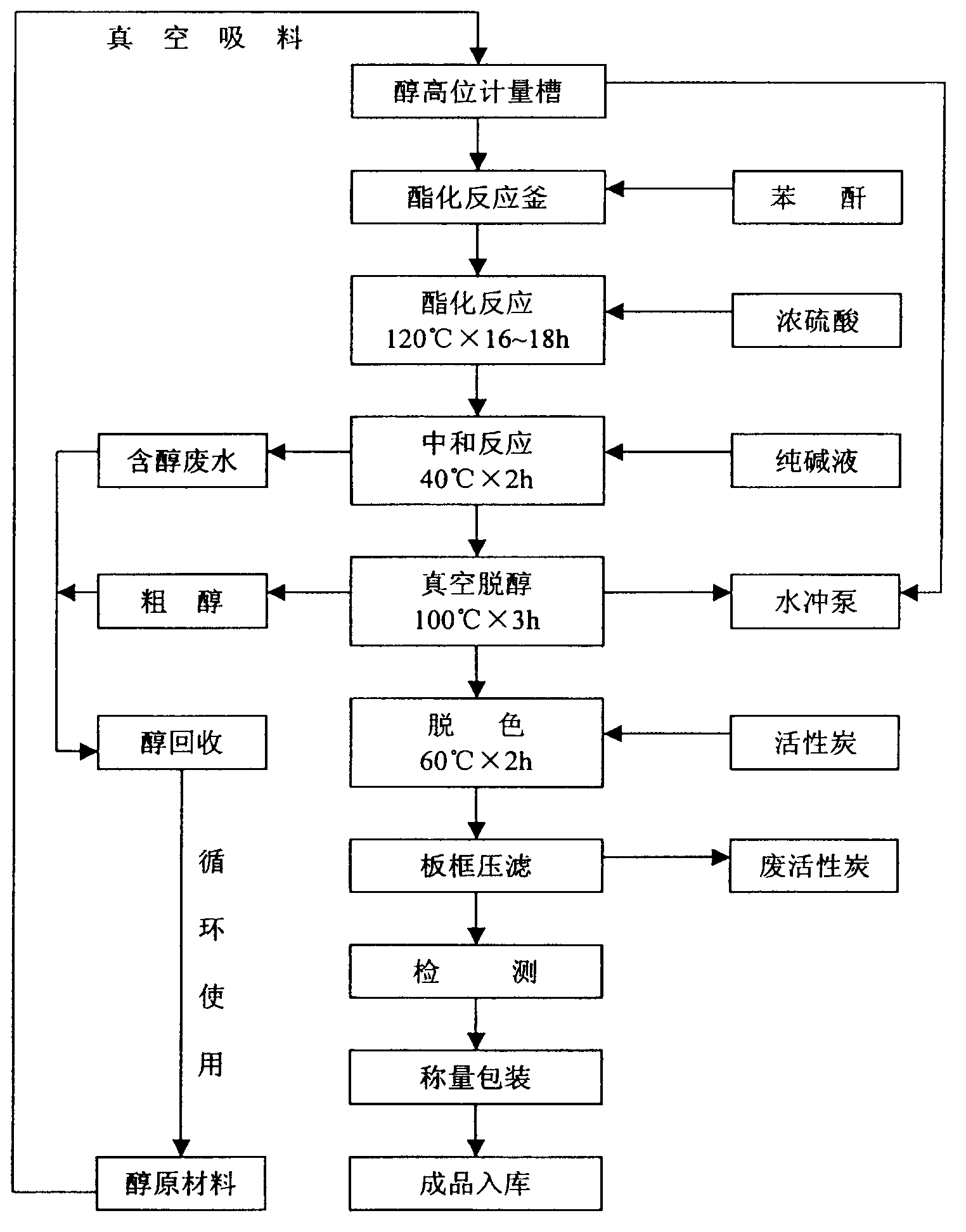

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical solution of the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0028] The purity of methanol and phthalic anhydride used in this embodiment are both = 99%.

[0029] A preparation method for dimethyl phthalate, comprising the following steps:

[0030] 1. Esterification process

[0031] 1. Raw material ratio

[0032] Phthalic anhydride Methanol Sulfuric acid Activated carbon Recycled alcohol

[0033] a. 1600kg 2400kg 9kg 5kg /

[0034] b. 1600kg 1700kg 9kg 5kg 875kg

[0035] 2. Prepare materials, check equipment, start

[0036] a. Put in the prepared methanol first, then turn on the blower to throw phthalic anhydride, and start stirring at the same time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com