Construction method for connection joint of prefabricated sandwich side fascia

A technology for connecting nodes and construction methods, applied in the processing of building materials, construction, building construction, etc., can solve problems such as low operation efficiency, and achieve the effect of improving construction efficiency and simplifying the treatment of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

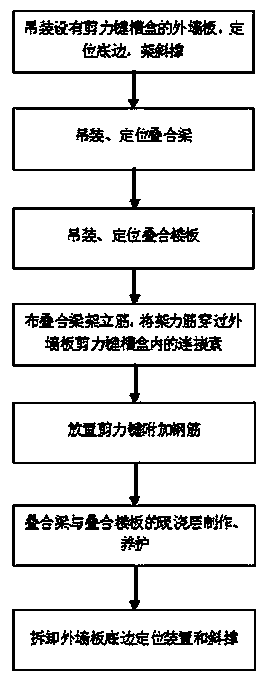

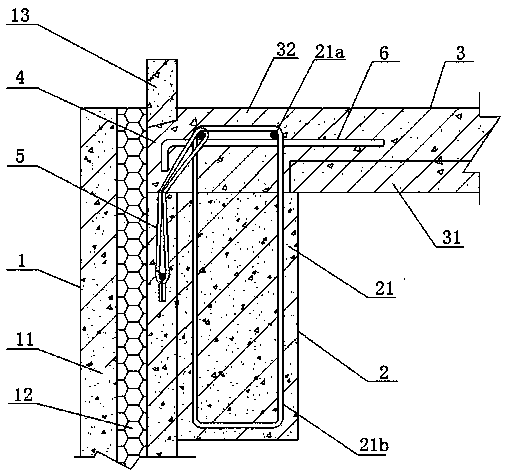

[0017] The construction method of the connection node of the prefabricated sandwich exterior wall panel of this preferred embodiment is aimed at figure 2 The installation and construction method of the connection node between the prefabricated sandwich exterior wall panel and the laminated floor slab, the steps are as follows figure 1 As shown, it specifically includes: S0, setting the composite beam including the prefabricated layer and the cast-in-place layer, setting the prefabricated sandwich exterior wall panel including the outer leaf plate, the insulation layer and the inner leaf plate connected to the side of the composite beam, and the inner leaf plate Set the shear keyway at the connection with the cast-in-place layer of the composite beam, and set the shear keyway matching the shear keyway at the position corresponding to the shear keyway of the inner leaf plate on the cast-in-place layer of the composite beam; S1, hoisting Prefabricated sandwich exterior wall pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com