Double-stage enthalpy-increased rotor compressor and air conditioner and heat pump water heater with same

A technology of a rotor compressor and a pump body is applied in the field of compressors to achieve the effects of improving the utilization rate, high energy efficiency, and improving the efficiency of refrigeration and heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

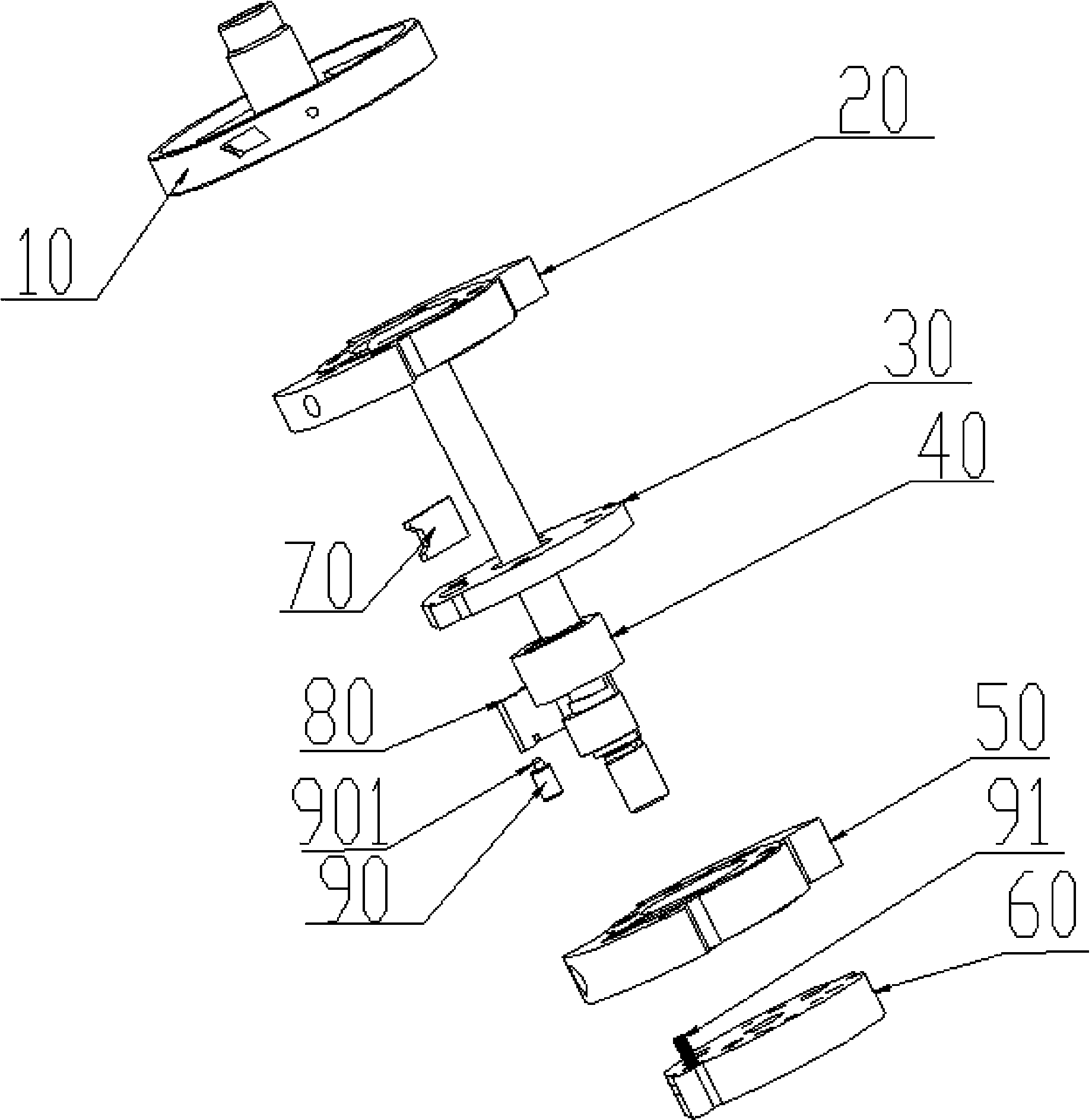

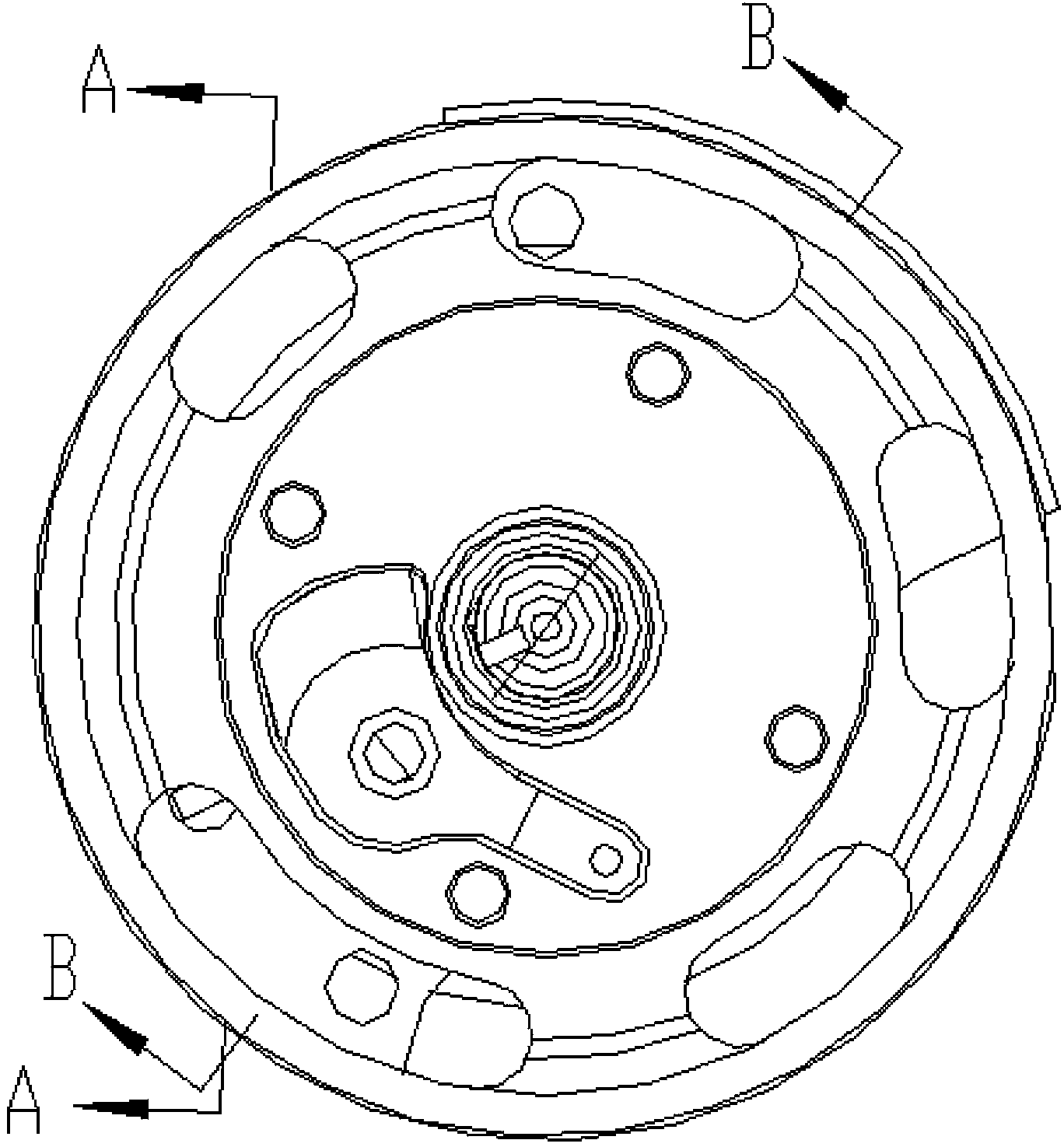

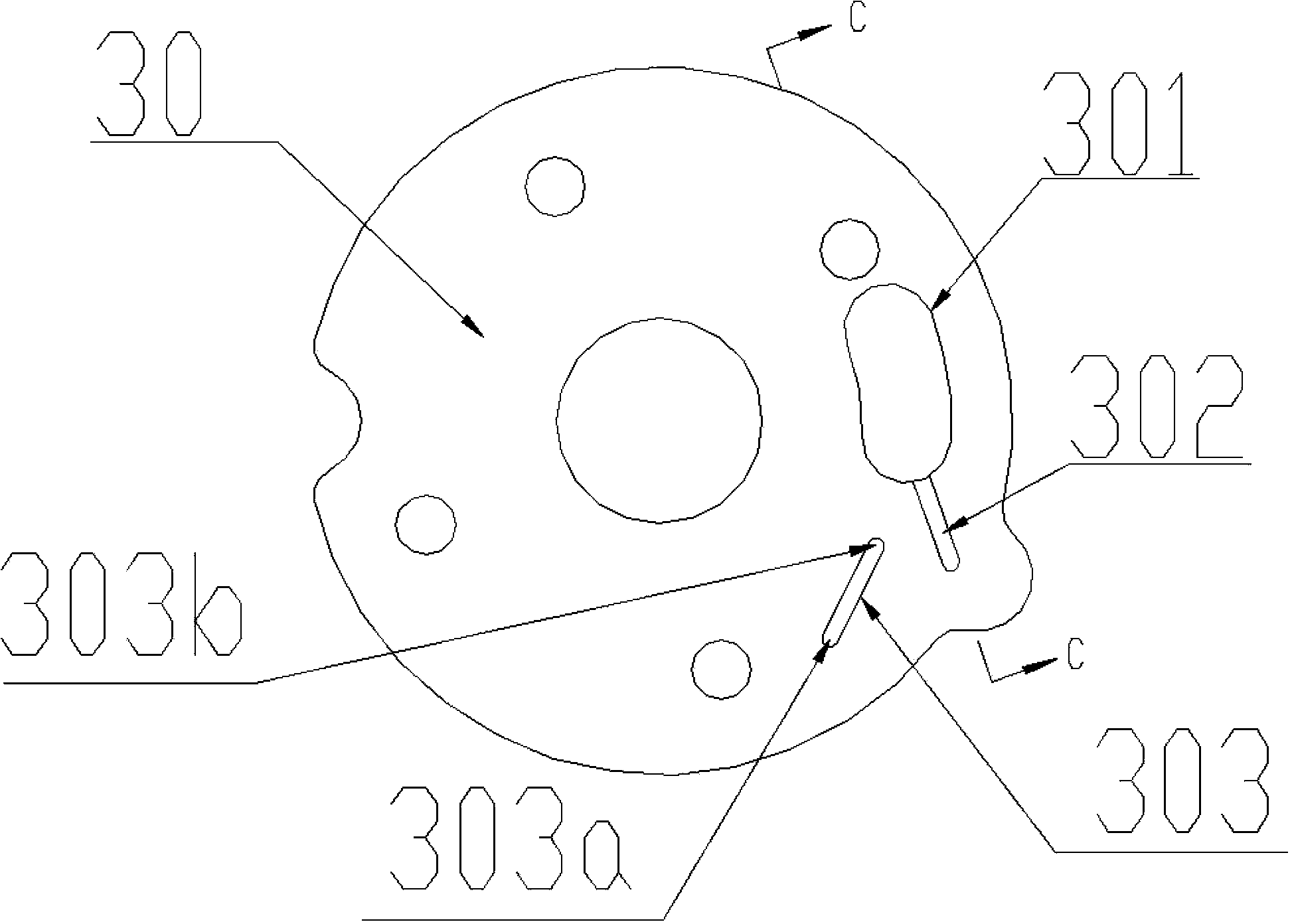

Method used

Image

Examples

Embodiment 2

[0085] The single-stage and double-stage compression work and switching principle of Embodiment 2 and Figure 14 The same as shown, the difference lies in the structure of the liquid distributor and the arrangement of the liquid reservoir. The liquid distributor 1a of the second embodiment is a double-pipe liquid distributor, that is, the liquid distributor 1a has two air outlet pipes, 2a and 2b respectively, and the first air outlet pipe 2a communicates with the refrigerant suction port 504 of the second cylinder 50, The second air outlet pipe 2b constitutes the first air inlet pipe of the three-way valve 22, that is, the first air inlet pipe of the three-way valve 22 is the same pipeline as the second air outlet pipe 2b of the liquid separator 1a. The three-way valve 22 also has a second air intake pipe 4a, and the second air intake pipe 4a communicates with the enthalpy increasing pipe 5 through the liquid reservoir 3. The three-way valve 22 also has an air outlet pipe 8a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com