Self-backflow type sealing structure of railway vehicle gear box

A technology of rail vehicle and sealing structure, which is applied to belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problem that the reliability of sealing cannot meet the requirements of gearboxes, and is not conducive to the lightweight, compact design of gearboxes. The internal pressure of the gearbox increases and other problems, so as to achieve the effect of reliable effect, light and compact structure, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

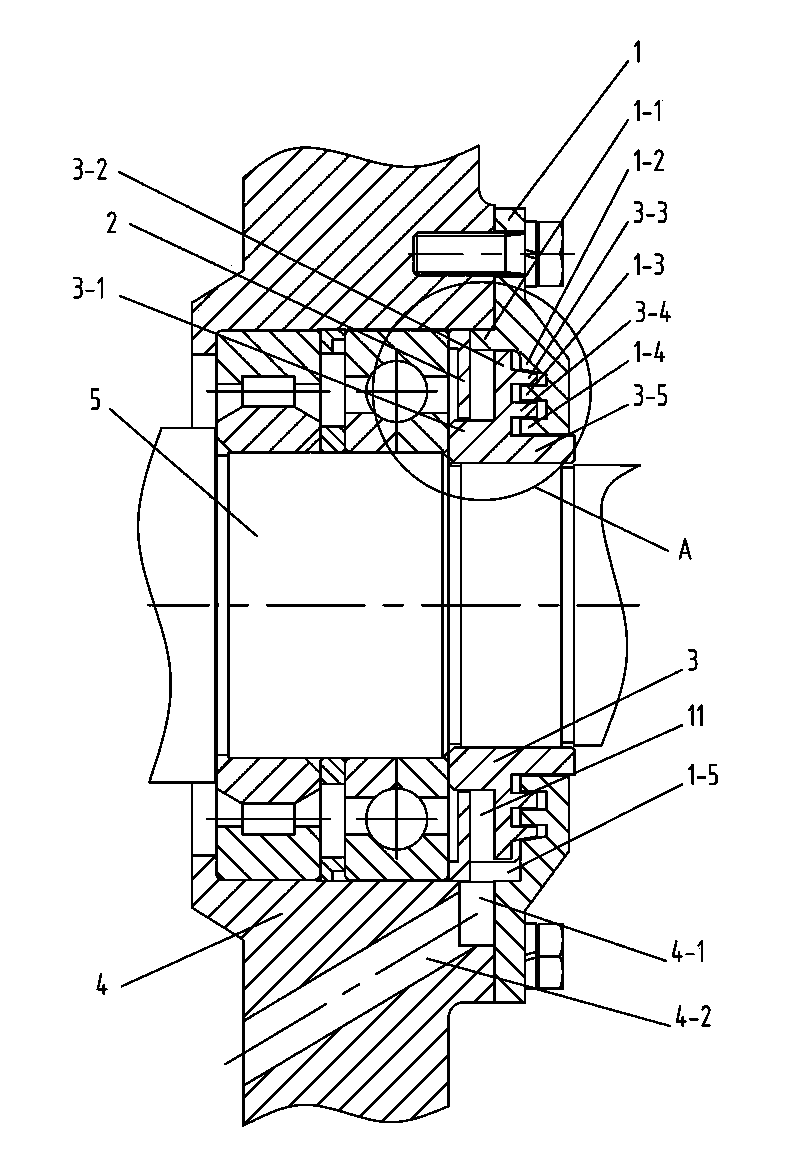

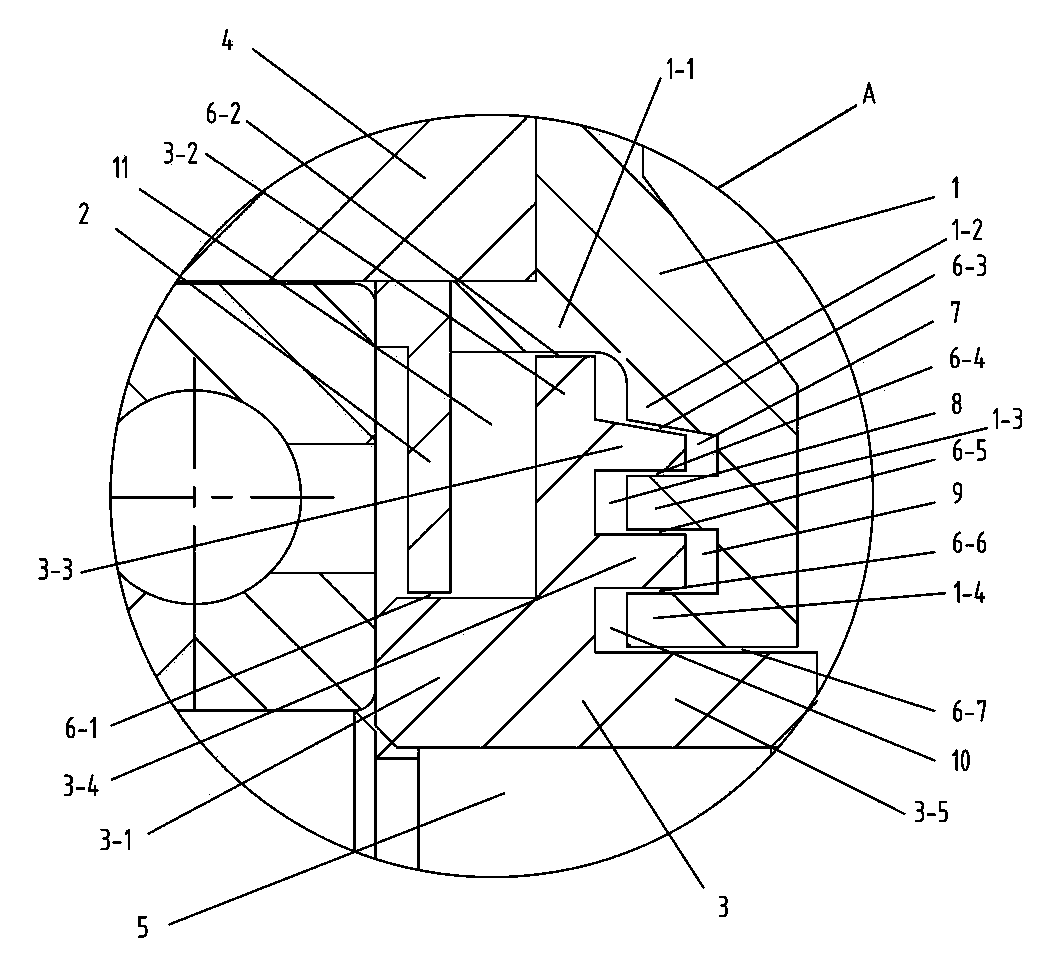

[0014] Such as figure 1 , 2 As shown, the self-reflux sealing structure of the rail vehicle gearbox of the present invention includes a sealing cover 1 and an oil baffle plate 2 fixed on the box body 4, and a sealing ring 3 fixed on the rotating shaft 5. The sealing cover 1 It has the first flange 1-1 of the sealing cover, the second flange 1-2 of the sealing cover, the third flange 1-3 of the sealing cover, the fourth flange 1-4 of the sealing cover and the oil return gap 1-5 of the sealing cover, A first sealing groove 7 is formed between the second flange 1-2 of the sealing cover and the third flange 1-3 of the sealing cover, and a sealing groove 7 is formed between the third flange 1-3 of the sealing cover and the fourth flange 1-4 of the sealing cover The third seal groove 9; the seal ring 3 has a seal ring first flange 3-1, a seal ring second flange 3-2, a seal ring third flange 3-3, a seal ring fourth flange 3- 4 and the fifth flange 3-5 of the sealing ring, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com