Structure and method for preventing reinforcing steel from being corroded in highly-corrosive environment

A corrosive environment, anti-corrosion technology, used in building components, building insulation materials, etc., can solve problems such as adverse effects, exposed steel insulation layer is difficult to remove straight thread connections, etc., to achieve reliable sealing effect, outstanding anti-corrosion effect, and operation process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

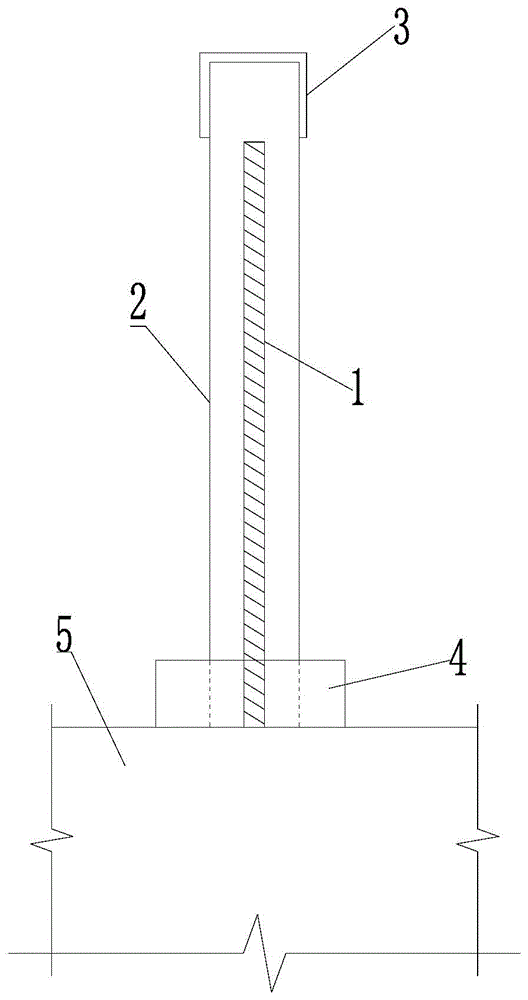

[0023] Such as figure 1 As shown, the anti-corrosion structure of steel bar under the highly corrosive environment provided by the present invention comprises a film protective layer, sleeve pipe 2, sealing mouth 3 and sealing mortar block 4, the film protective layer is wrapped on the exposed steel bar 1, and the sleeve pipe 2 is sleeved on the On the steel bar wrapped with the film protective layer, the sealing mortar block 4 is sealed at one end of the casing 2 close to the concrete structure 5 , and the sealing mask 3 is set at the other end of the casing 2 .

[0024] Specifically, the film protection layer is a plastic film layer, and of course other waterproof materials can also be used.

[0025] Specifically, the casing 2 is a PVC pipe, or other commonly used pipe materials.

[0026] In the above embodiment, the exposed steel bar 1 of the concrete structure 5 is wrapped with a plastic film to form the first protective layer, and then the casing 2 is put on. The top of ...

Embodiment 2

[0028] The method for anti-corrosion of steel bar under the high corrosion environment provided by the present embodiment comprises the following steps:

[0029] S1. Wrap the exposed steel bar 1 with a plastic film and wrap it with adhesive tape to form the first layer of protection;

[0030] S2. Covering the wrapped exposed steel bar 1 with a casing 2 matching the diameter of the exposed steel bar 1 to form a second layer of protection;

[0031] S3, using the sealing mouth 3 to seal the top of the casing 2;

[0032] S4. Use mortar to seal the gap between the sleeve pipe 2 and the concrete structure 5 .

[0033] In the anti-corrosion method for steel bars in a highly corrosive environment provided by the present invention, two layers of protection are provided outside the exposed steel bars 1 to isolate the exposed steel bars 1 from air and corrosive media to achieve the purpose of anti-corrosion of steel bars. The entire operation process is simple and the sealing effect is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com