Array substrate and touch display device

An array substrate and sensing electrode technology, which is applied in the fields of instrumentation, computing, electrical and digital data processing, etc., can solve the problems of weakening the electric field inductive capacitive coupling between the driving electrode and the sensing electrode, increasing the resolution distance, and increasing the center distance, etc. Electrode spacing, increased sensing area, good effect of capacitive coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

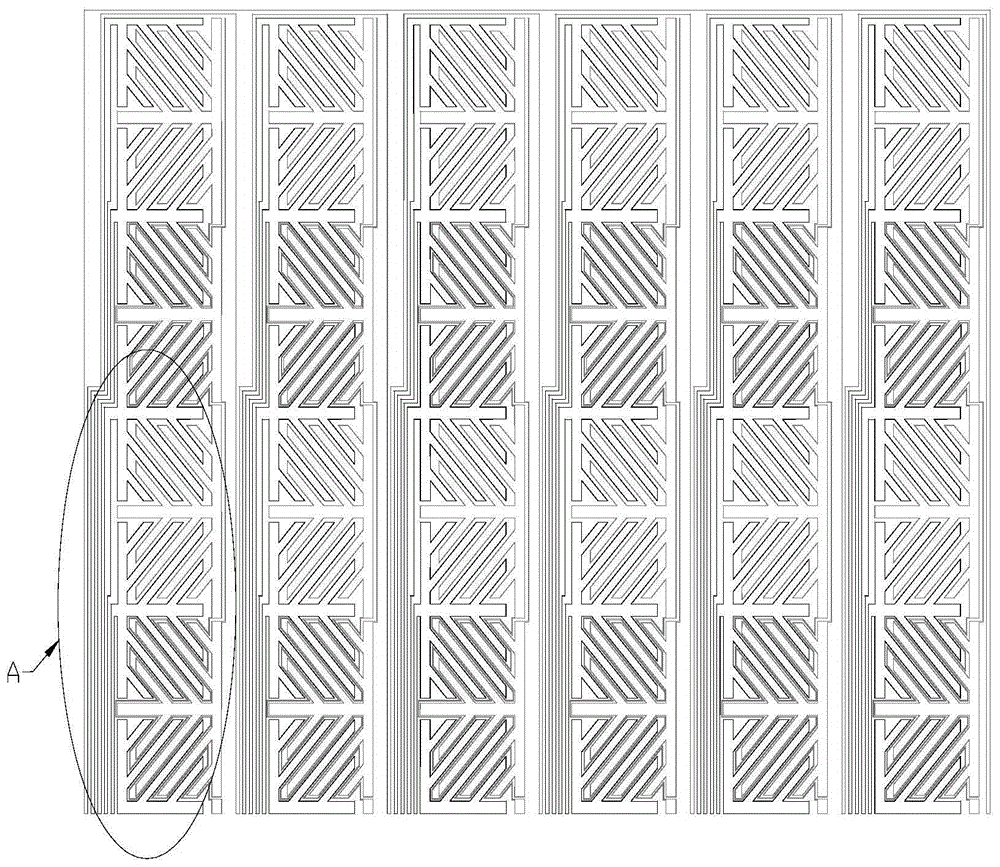

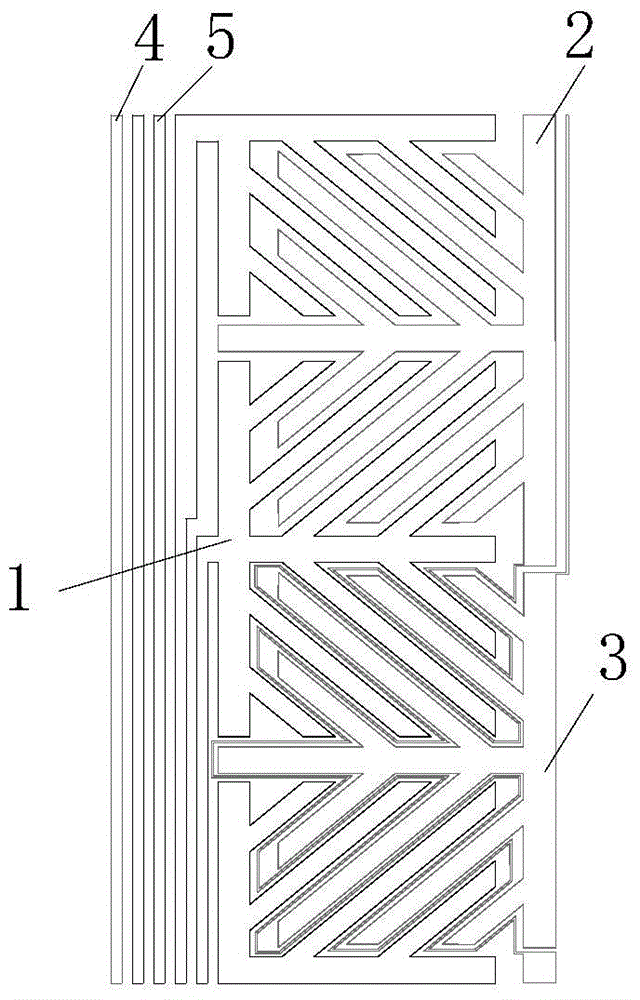

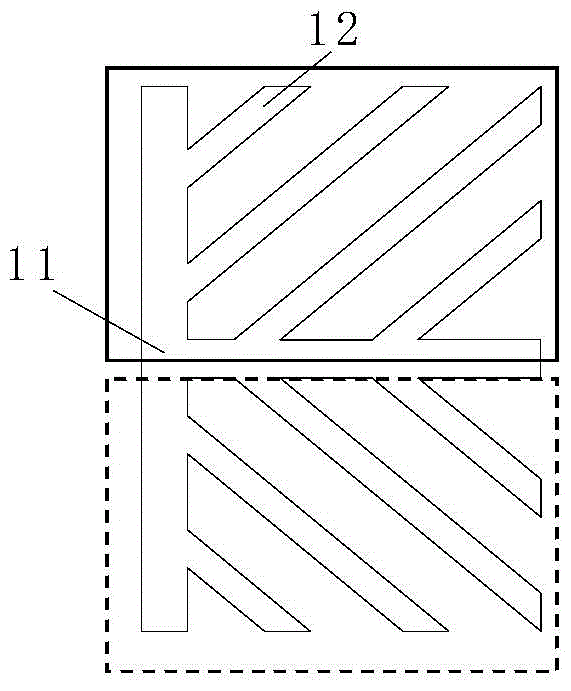

[0025] The present invention provides a display device, which includes an array formed by several driving electrodes and sensing electrodes, and the driving electrodes and sensing electrodes have the same structure, specifically as Figure 1~5 As shown, the structure includes: T-shaped electrode main body (driving electrode main body 11, sensing electrode main body 21) and several electrode branches (driving electrode branch body 12, sensing electrode branch body 22) symmetrically distributed and connected to the electrode main body. , to form two symmetrical parts of the first sub-electrode and the second sub-electrode (such as image 3 The parts shown in the solid and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com