Motor stator having high coil space factor and adopting pressed trapezoidal enamelled wires

A motor stator and enameled wire technology, applied in the direction of magnetic circuit shape/style/structure, winding insulation shape/style/structure, magnetic circuit static parts, etc., can solve the problems of high labor intensity, low motor operation efficiency, high cost, etc. , to achieve the effect of reducing labor intensity, improving production efficiency, and low calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

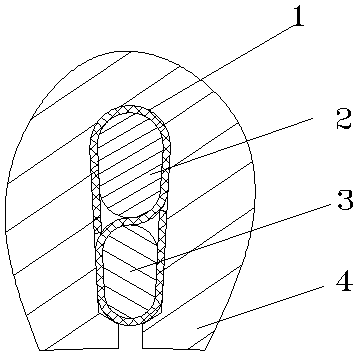

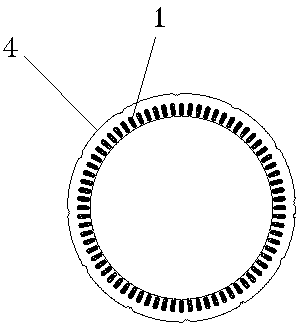

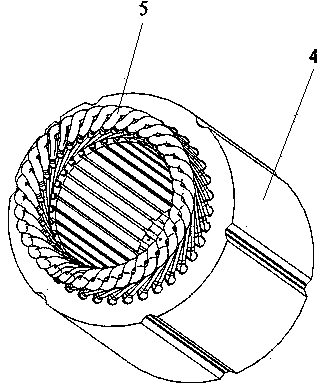

[0020] Attached below Figure 1-3 The specific embodiments of the present invention are further described.

[0021] see Figure 1-3 , first fold the slot insulating paper 1 into an "S" shape and insert it into the slot of the stator core 4, then use special equipment to cut off the corresponding length of enameled wire and peel off the paint film at both ends, bend it into a "U" shape and press it into a The slot shape of the stator core 4 and the trapezoidal shape of the same size are twisted by 1 wire span at both ends to form the inner layer enameled wire 2 and the outer layer enameled wire 3, and then insert the stator core 4 slot in sequence from the end of the stator iron core The inner layer and the outer layer separated by a wire span, the number of U-shaped wires is the same as the number of slots of stator core 4, insert all U-shaped wires in sequence, and then insert all inner layer enameled wires 2 and all outer layer enameled wires 3 The ends of the coils are tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com