Dust collector with motor shock absorption structure

A technology for vacuum cleaners and shock-absorbing media, applied in the field of vacuum cleaners with motor shock-absorbing structures, can solve the problems of reducing user experience, reducing vibration without innovation, and not greatly improving the effect, so as to improve user experience, reduce vibration amplitude, Vibration noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

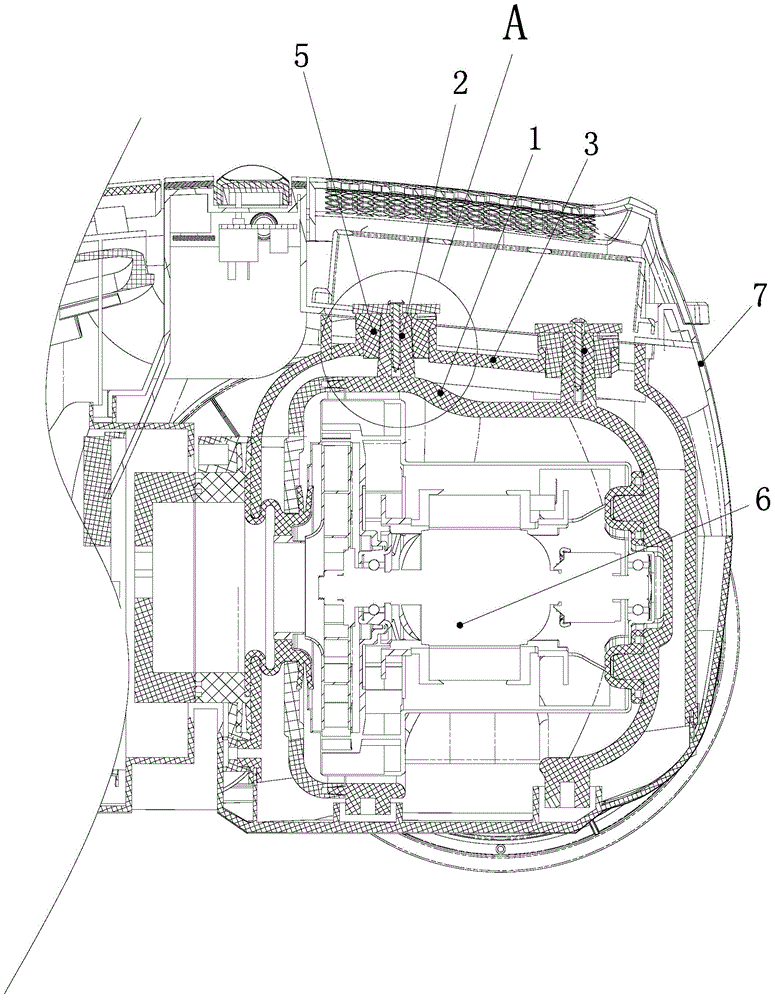

[0016] figure 1 and figure 2 A specific embodiment of the vacuum cleaner with motor shock absorbing structure of the present invention is shown, the vacuum cleaner includes a motor inner cover 1 and a motor outer cover 2 housed outside the motor inner cover 1, wherein a motor 6 is installed in the motor inner cover 1, The motor cover 2 is fixed in the vacuum cleaner housing 7 .

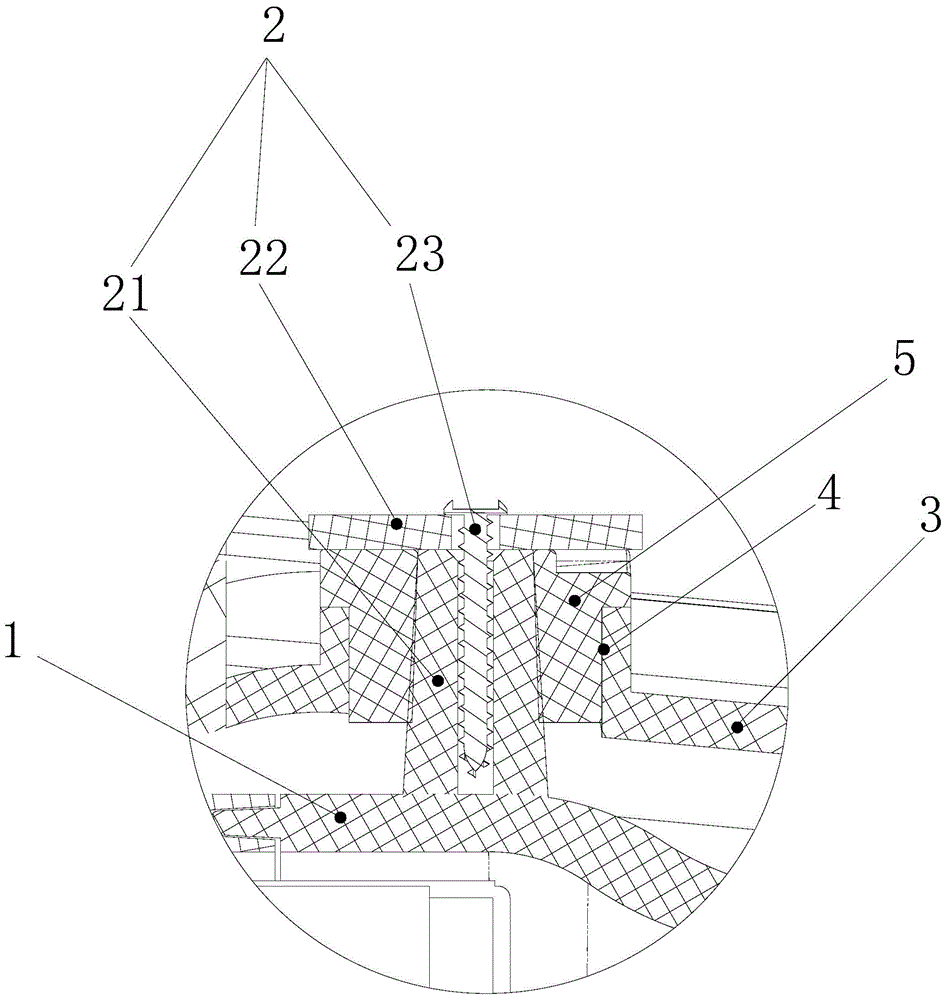

[0017] The key improvement of this embodiment is that: the motor inner cover 1 is suspended and fixed in the motor outer cover 3 through the hanging arm 2 . The specific structure is as follows:

[0018] A suspension hole 4 is formed on the motor cover 3, and a shock absorption medium 5 with a vertical through hole (not marked in the figure) is arranged in the suspension hole 4, and the hanging arm 2 is suspended on the shock absorption medium 5 On the vertical through-hole, and the hanging arm 2 and the motor cover 3 are not in direct contact and are completely isolated, and the entire motor inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com