Anti-sliding punching transmission mechanism for sheet hot forming machine

A technology of thermoforming machine and transmission mechanism, which is applied in the direction of metal processing, etc., which can solve problems such as insufficient punching force, movable templates for punching, sliding of punching upper knife, hidden safety hazards, etc., so as to increase punching force and improve Effect of thermoforming and die cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below with reference to the drawings and embodiments.

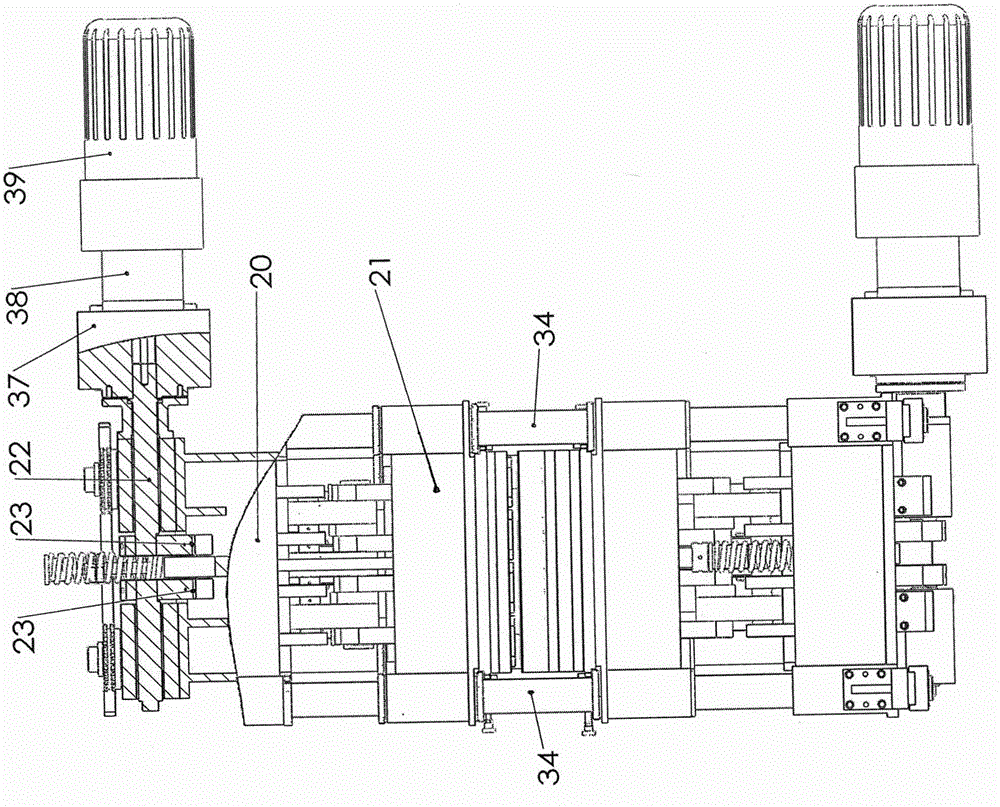

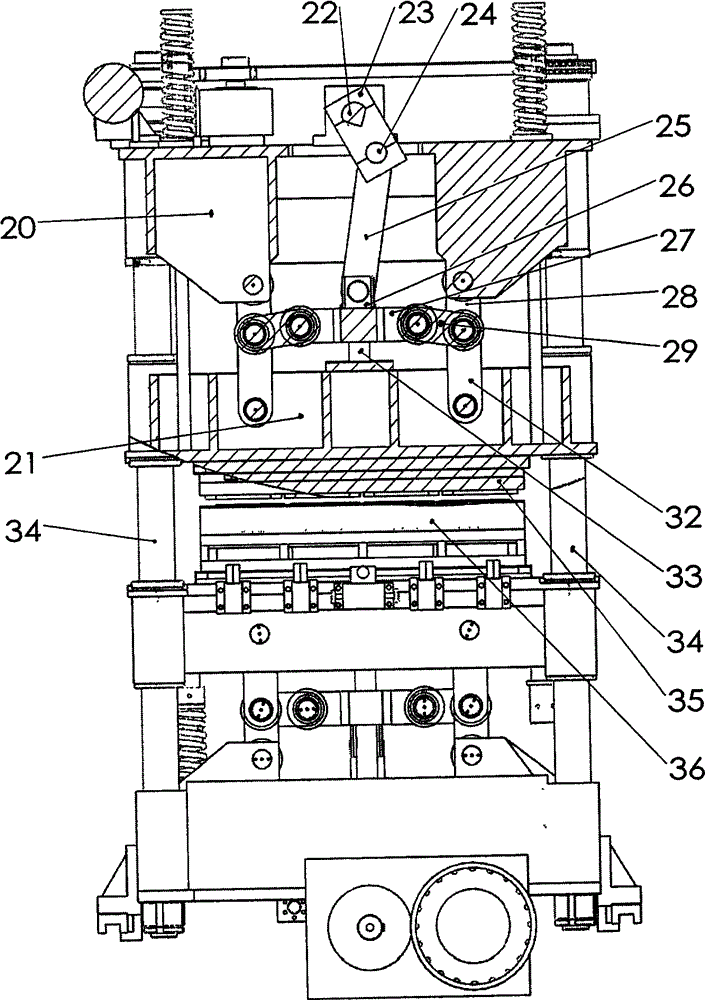

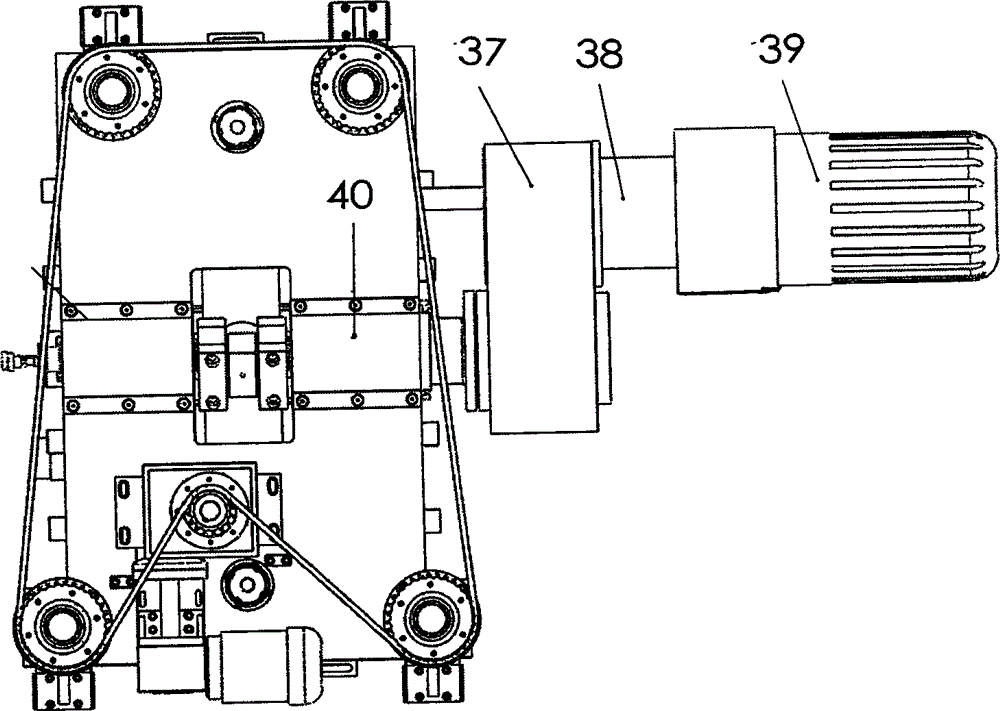

[0010] refer to Figure 1 to Figure 3 It can be seen that the non-slip punching transmission mechanism of the sheet thermoforming machine of the present invention includes a punching motor 39, a punching reducer 37, a punching upper beam 20, a punching movable template 21, and a column 34. The punching reducer 37 There is an output shaft 22 on the top, and the punching reducer 37 is installed on the reducer shaft seat 40, and a bidirectional backstop 38 is installed between the punching motor 39 and the punching reducer 37. In order to increase punching strength, the output shaft 22 links to each other with the opening and closing mold pull rod 25 (with the upper pull rod shaft 24) through the rotating swing arm 23. The opening and closing mold pull rod 25 has a pull rod shaft 24. The pull rod 25 is connected to the "ten"-shaped connecting rod 27 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com