Automatic bag replacement and placing device and method for intelligent garbage can

A technology of bagging device and trash can, which is applied in the field of automatic bag changing and bagging devices for intelligent trash cans, can solve the problems of automatic and efficient bag changing and bagging, and achieve the effects of simple structure, labor cost saving, and health protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

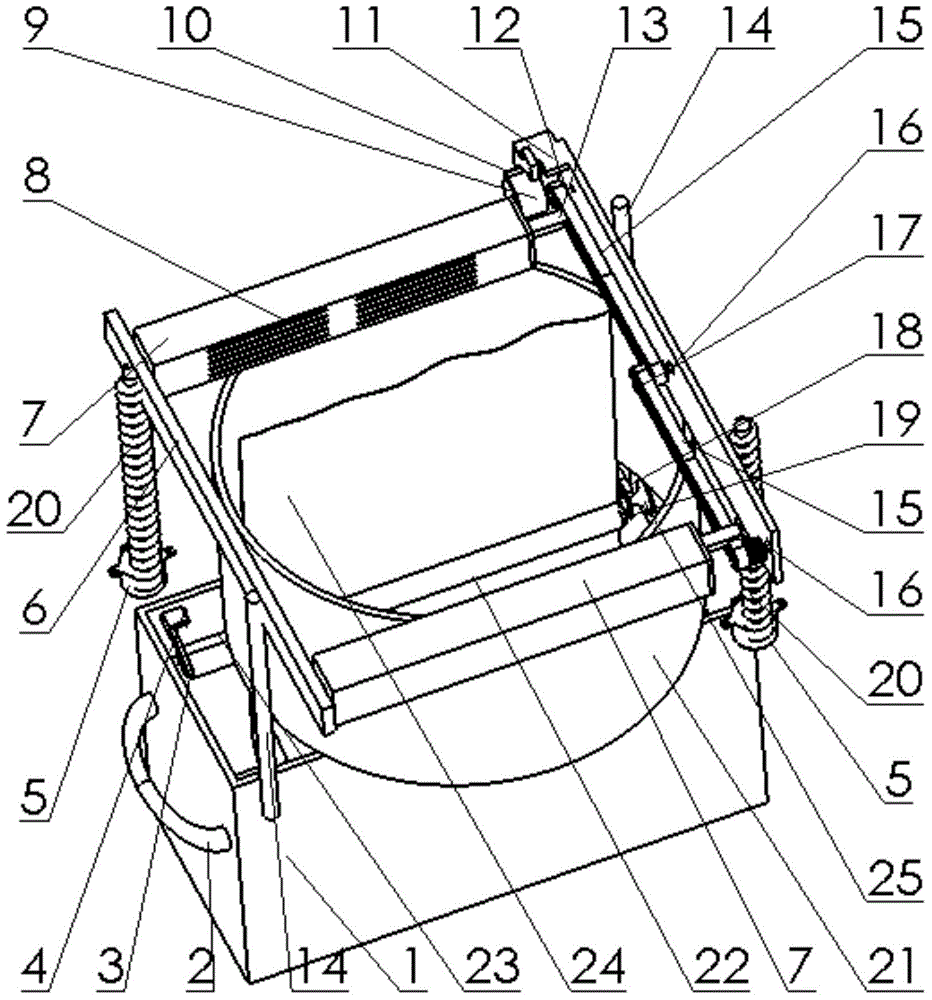

[0039] Such as figure 1 As shown, an automatic bag changing and bagging device for a smart trash can includes a drum 21, a first rubber shaft 22, a second rubber shaft 23, a first side plate 6, a second side plate 11, and a fan bag opening device 7; The top of the drum 21 is provided with an opening, and the bottom is provided with an input port. The first rubber shaft 22 and the second rubber shaft 23 are arranged in parallel below the input port for pulling the tap of the rolling garbage bag 24 from the place. The input port is clamped and transported to the drum 21, and the rising height of the rolling garbage bag 24 is detected; the first side plate 6 and the second side plate 11 are arranged in parallel above the opening, Two air blower bag opening devices 7 that can move towards and oppositely are arranged between the first side plate 6 and the second side plate 11.

[0040] As an improvement of the above-mentioned embodiment, the first side plate 6 and the second side plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com