Multi-scale sample grabbing, lifting and overturning mechanism provided with mold box

A mold box and multi-scale technology, applied in the direction of lifting devices, etc., can solve the problems of potential safety hazards, cumbersome operations, and low efficiency, and achieve the effects of eliminating potential safety hazards, simplifying operations, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

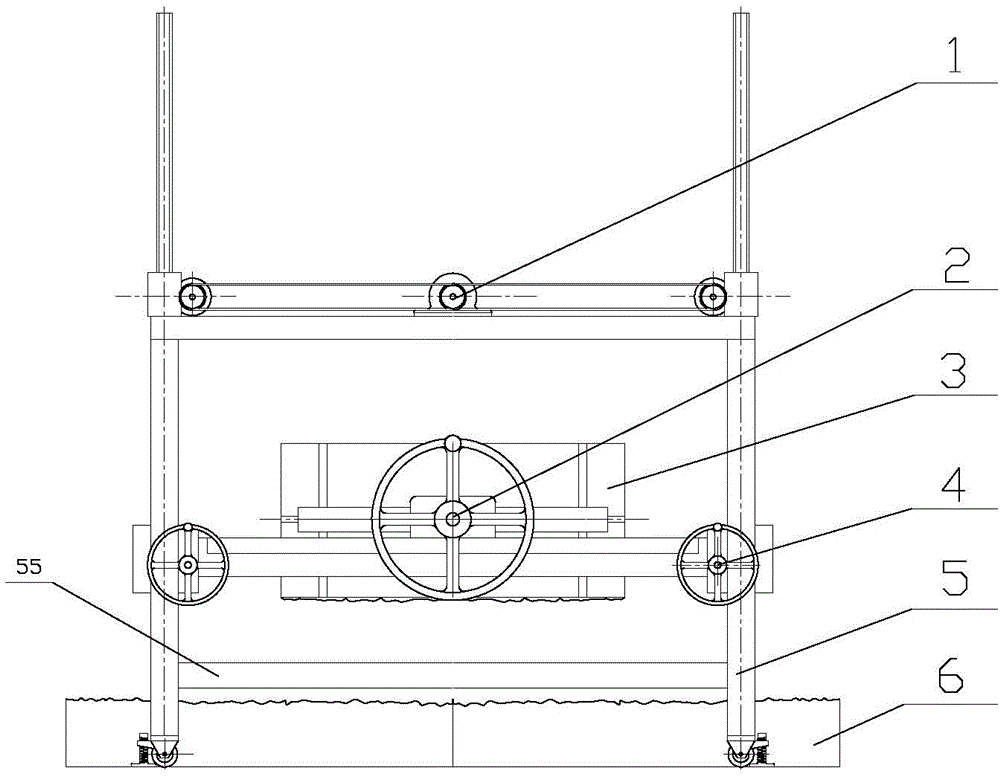

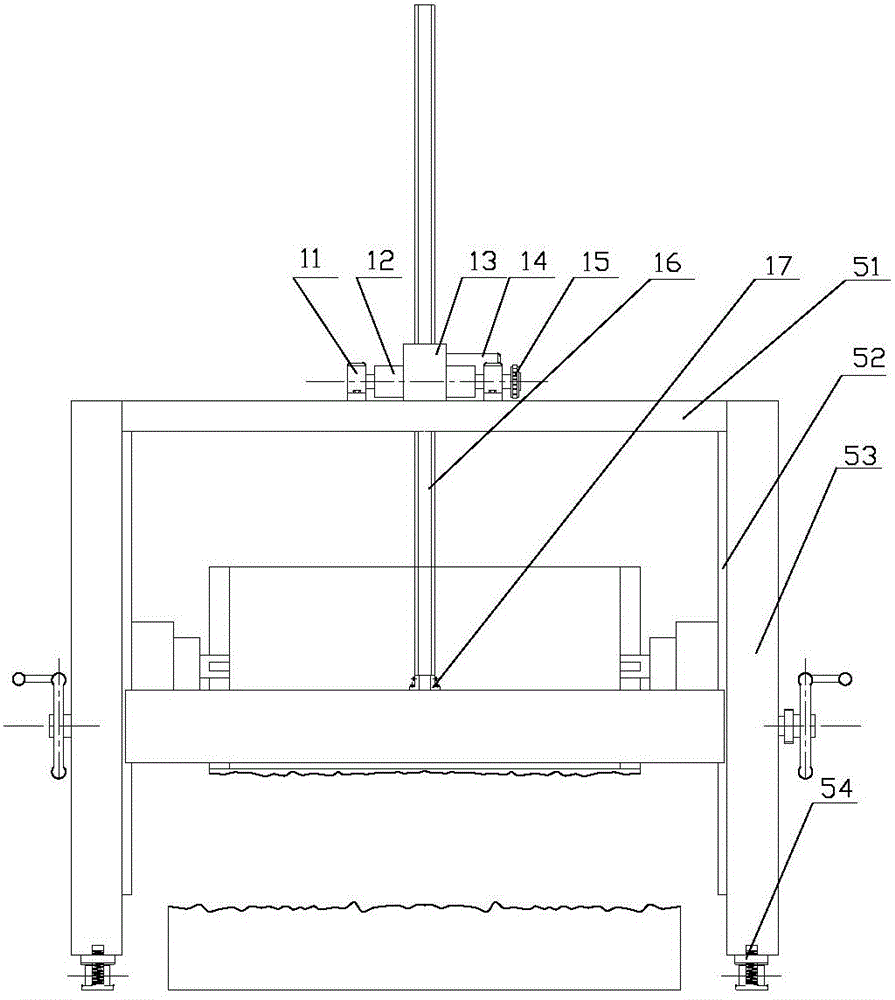

[0029] refer to Figure 1 to Figure 10 , a multi-scale sample grasping and turning mechanism with a mold box, including a lifting mechanism 1, a turning mechanism 2, a mold box 3, a spacing adjustment mechanism 4 and a frame 5, and a lifting mechanism is installed on the top of the frame 5, and the frame The two sides of the space adjustment mechanism are installed, and a turning mechanism is installed between the two space adjustment mechanisms. The mold box 3 is placed on the rock and is in the middle and lower part of the frame.

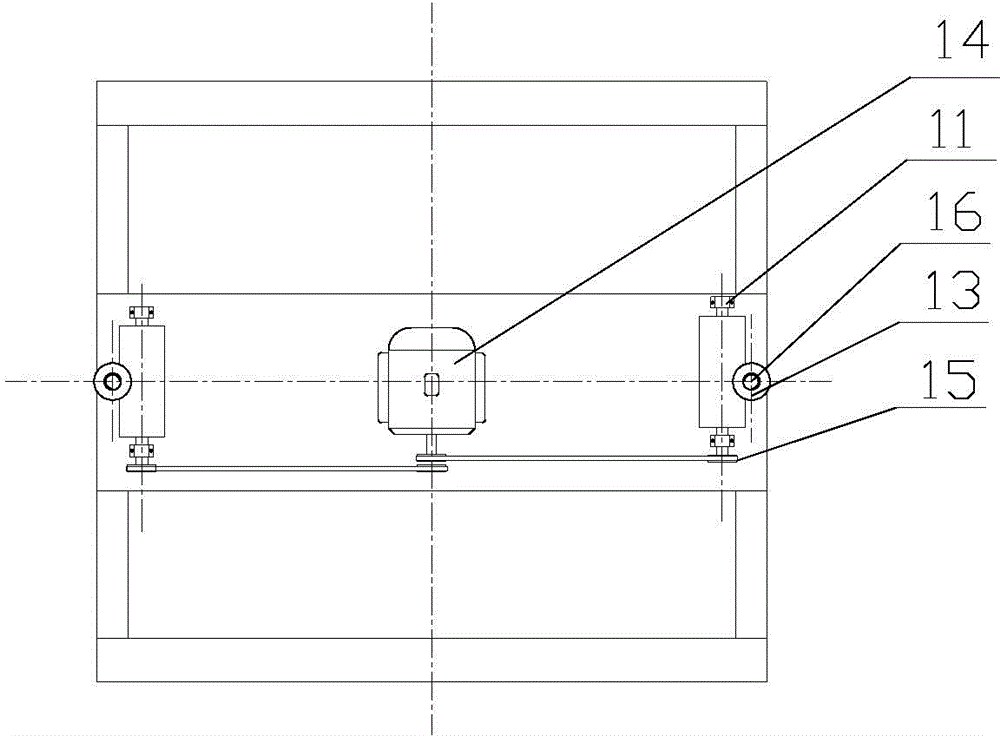

[0030] The lifting mechanism includes a bearing housing 11 , a worm wheel 12 , a worm screw seat 13 , a motor 14 , a sprocket wheel 15 , a worm screw 16 and a connector 17 . Worm gear and worm mechanisms are installed on both sides of the frame 5. One end of the worm wheel 12 is installed with a bearing seat 11, and the other end passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com