A method for reducing excess sludge

A treatment method and technology for excess sludge, applied in the fields of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing chemical pollution, increasing treatment costs, etc., to simplify the operation process and save money. Investment cost, reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

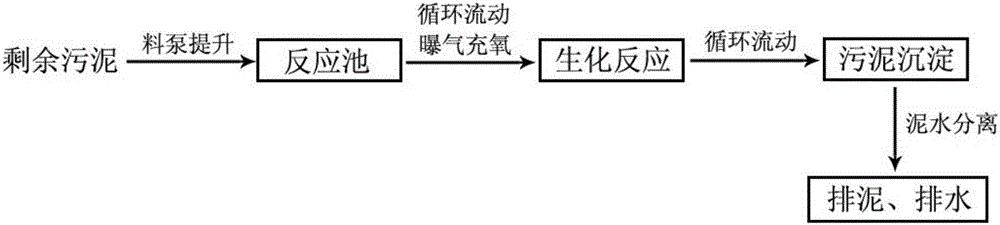

Method used

Image

Examples

Embodiment 1

[0023] (1) Sludge intake and drainage: When mud intake, drainage and sludge discharge, the mud-water mixture in the reaction tank does not undergo circulation reaction and aeration, and the sludge to be treated enters the reaction tank in the way of upward flow from the bottom of the reaction tank by lifting the material pump , control the flow rate of the mud-water mixture in the reaction tank to 0.4m / h, the driving action of the mud water in the reaction tank will discharge the sewage separated from the upper part of the reaction tank from the outlet pipe at the upper part of the reaction tank, and the inorganic sludge after digestion and reduction will flow from the bottom of the reaction tank The internal mud discharge pipe is discharged regularly;

[0024] (2) Biochemical reaction: During the reaction period, the reaction tank does not enter the mud and drain the mud, and use the lifting effect of the material pump to make the mud-water mixture in the reaction tank circula...

Embodiment 2

[0027] (1) Sludge intake and drainage: When mud intake, drainage and sludge discharge, the mud-water mixture in the reaction tank does not undergo circulation reaction and aeration, and the sludge to be treated enters the reaction tank in the way of upward flow from the bottom of the reaction tank by lifting the material pump , control the upward flow velocity of the mud-water mixture in the reaction tank to 0.5m / h, the driving action of the mud water in the reaction tank will discharge the sewage separated from the upper part of the reaction tank from the outlet pipe at the upper part of the reaction tank, and the inorganic sludge after digestion and reduction will flow from the bottom of the reaction tank The internal mud discharge pipe is discharged regularly;

[0028] (2) Biochemical reaction: During the reaction period, the reaction tank does not enter the mud and drain the mud, and use the lifting effect of the material pump to make the mud-water mixture in the reaction t...

Embodiment 3

[0031](1) Sludge intake and drainage: When mud intake, drainage and sludge discharge, the mud-water mixture in the reaction tank does not undergo circulation reaction and aeration, and the sludge to be treated enters the reaction tank in the way of upward flow from the bottom of the reaction tank by lifting the material pump , control the upward flow velocity of the mud-water mixture in the reaction tank to 0.3m / h, the driving action of the mud water in the reaction tank will discharge the sewage separated from the upper part of the reaction tank from the outlet pipe at the upper part of the reaction tank, and the inorganic sludge after digestion and reduction will flow from the bottom of the reaction tank The internal mud discharge pipe is discharged regularly;

[0032] (2) Biochemical reaction: During the reaction period, the reaction tank does not enter the mud and drain the mud, and use the lifting effect of the material pump to make the mud-water mixture in the reaction ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com