A kind of coal tar diesel engine oil composition

A technology for diesel engine oil and composition, applied in the direction of lubricating composition, etc., can solve the problems of poor volatility, difficult ignition, serious afterburning, etc., achieve good high temperature oxidation stability, inhibit the formation of black sludge, and achieve excellent cleaning and dispersion. effect of effect

Active Publication Date: 2016-06-01

GUANGXI UNIV

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because of its rich aromatics, it is difficult to catch fire, the cetane number is -6.3, the atomization ability is low, the volatility is poor, the combustion is slow, the combustion constant volume is poor, and the afterburning is serious, and the combustion is incomplete; at the same time, it causes large smoke, high exhaust temperature, Low combustion efficiency and poor economy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

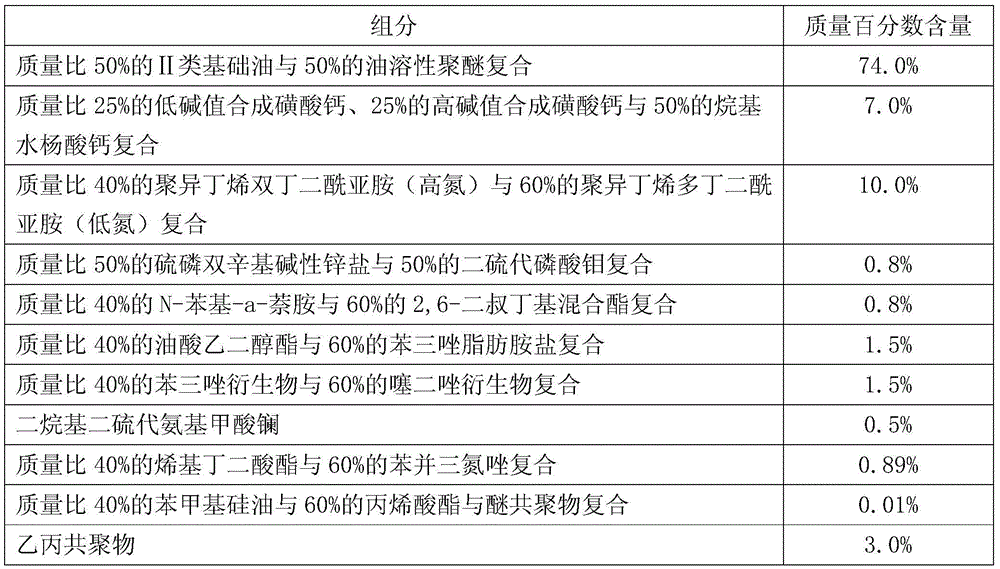

Embodiment 1

[0022] It is formed by blending the following components in mass percentage:

[0023]

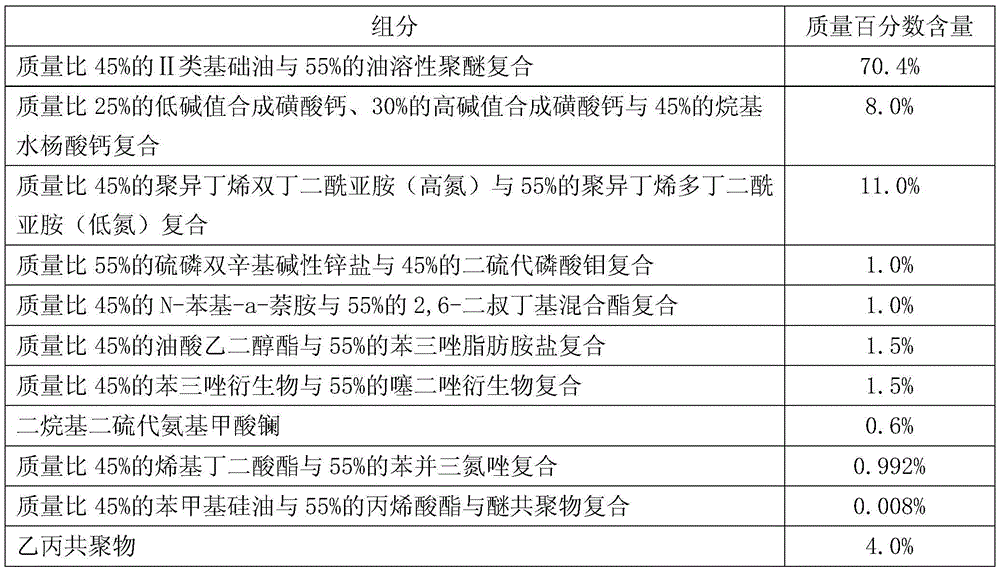

Embodiment 2

[0025] It is formed by blending the following components in mass percentage:

[0026]

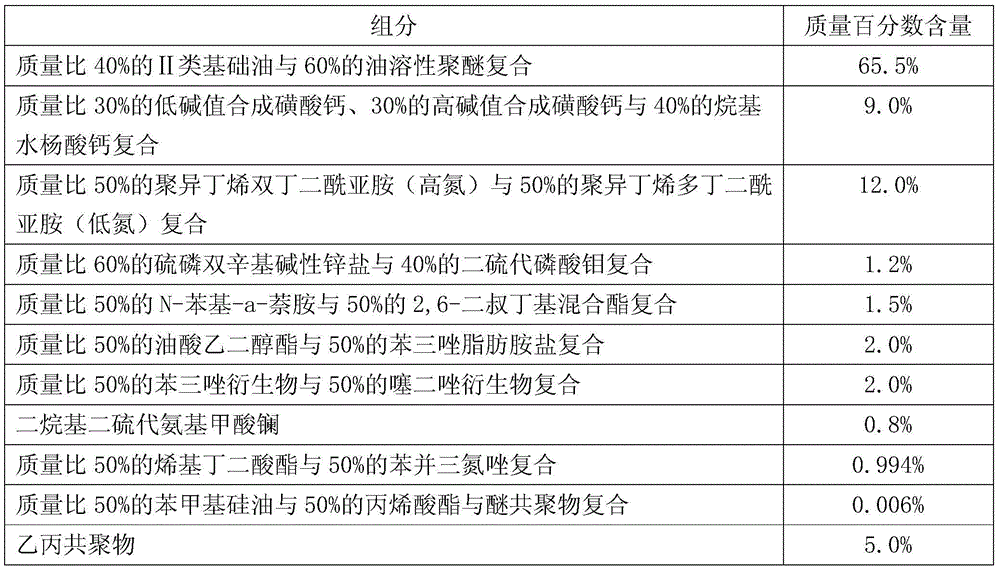

Embodiment 3

[0028] It is formed by blending the following components in mass percentage:

[0029]

[0030] The main physical and chemical index of embodiment 3 products:

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a coal tar diesel engine oil composition. Base oil II and oil-soluble polyether used as base oil are matched with multiple composite additives to obtain the composition. The composite additives comprise an antiwear additive, an antioxidant preservative, an antifoam agent, a viscosity index improver, a metal passivator, a detergent agent, a dispersing agent, an antioxidant, a reinforcing agent and an oily agent. The engine oil composition has excellent cleaning and dispersion effects, and prevents the piston ring from sticking. Due to excellent viscosity-temperature characteristic, excellent alkali number retentivity and excellent heat stability, the engine oil composition can inhibit the black oil sludge from generation, so that the engine is cleaner. Due to favorable high-temperature oxidation stability, high shear stability, favorable rubber compatibility, favorable cold-starting property and excellent fuel economical efficiency, the engine oil composition can not corrode the moving parts, has higher abrasion resistance under the condition of higher soot content, and effectively reduces the abrasion of the workpiece.

Description

technical field [0001] The invention belongs to the field of internal combustion engine lubricants, in particular to a coal tar diesel engine oil composition. Background technique [0002] Coal tar, also known as coal paste, coal distillate, and coal tar solution, is a black or dark brown viscous liquid obtained in the process of coal coking, with a specific gravity greater than 1. It has certain solubility, a special smell, and is flammable. Coal tar is one of the products in the crude gas generated by pyrolysis of coking industrial coal, and its output accounts for about 3% to 4% of the mass percentage of furnace coal. Coal tar is the main raw material of coal chemical industry, with tens of thousands of components. It mainly contains aromatic hydrocarbons such as benzene, toluene, xylene, naphthalene, and anthracene; and aromatic oxygen-containing compounds, such as phenolic compounds such as phenol, nitrogen-containing and sulfur-containing heterocyclic compounds, and o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10M169/04

Inventor 黄福川卢朝霞黄孝平陈彪李康春邓富康黄伊琳马骁飞刘宇恒黄旖瑶

Owner GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com