Direct insertion type quickly-connecting pipe fitting

An in-line, pipe fitting technology, used in mechanical equipment, couplings, etc., can solve the problems of increased cost of internal tooth gaskets, reduced sealing performance, and difficulty in satisfying customers, and achieves improved anti-detachment effect, good sealing performance, and improved The effect of anti-shedding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described in detail below:

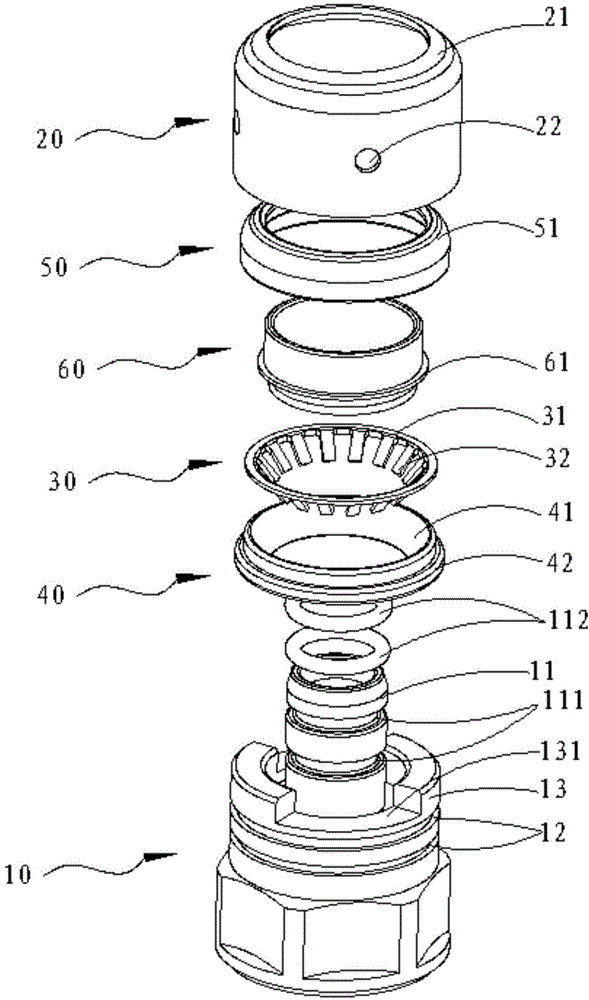

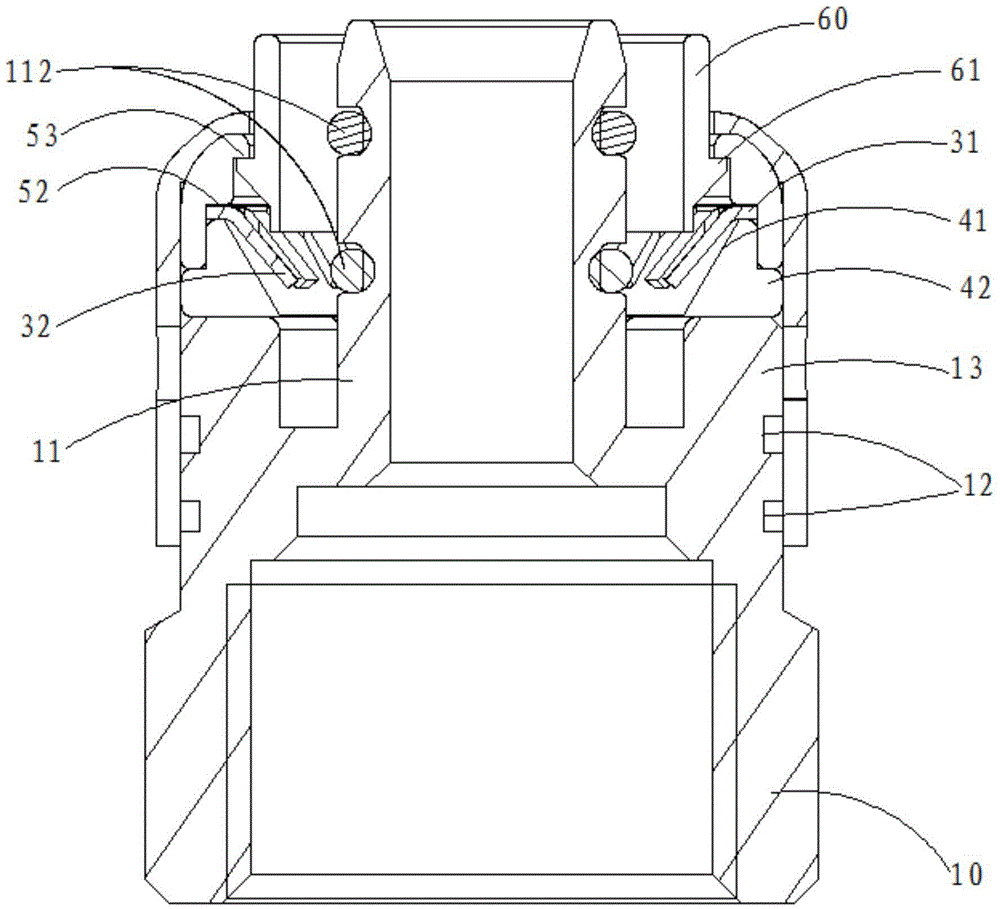

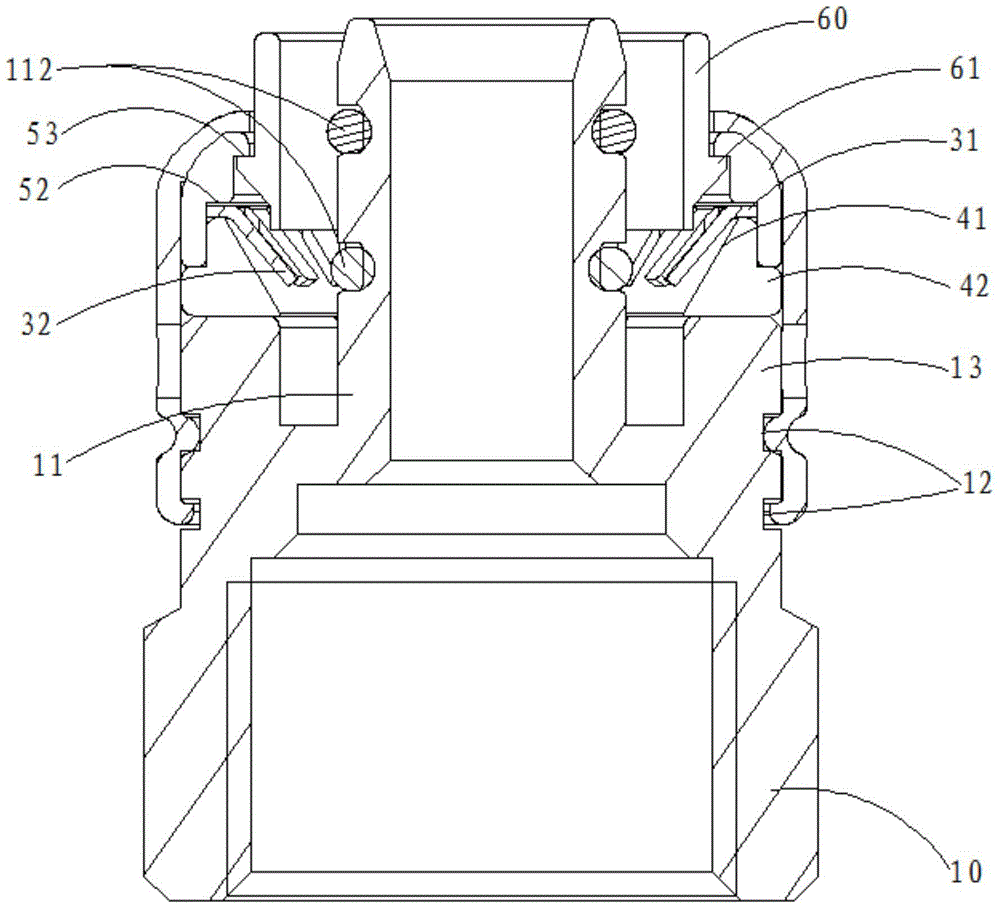

[0032] like figure 1 As shown, it is a schematic diagram of the explosion structure of the in-line quick-connect pipe fitting of the present invention. The in-line quick-connect pipe fitting of the present invention includes a pipe fitting main body 10 and a core 11 connected to the first end of the pipe fitting main body 10 , a fastening sleeve 20, an internal tooth washer 30, the fastening sleeve 20 is set outside the core body 11, one end of the fastening sleeve 20 is detachably connected to the first end of the pipe fitting main body 10, the fastening sleeve The other end of the sleeve 20 is a tapered opening 21. The internal tooth washer 30 includes a gasket 31 and several elastic teeth 32 connected to the gasket 31. The teeth 32 face the second end of the pipe body 10 The washer 31 is arranged obliquely, and is installed between the fastening sleeve 20 and the pipe main body 10 .

[0033] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com