Double close quick connector

A fast, male joint technology, applied in the direction of mechanical equipment, couplings, etc., to achieve the effect of ingenious design and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

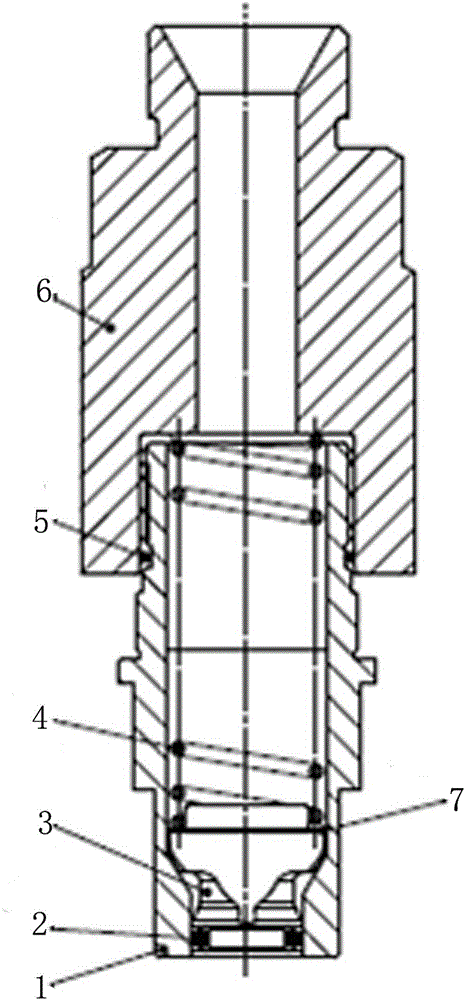

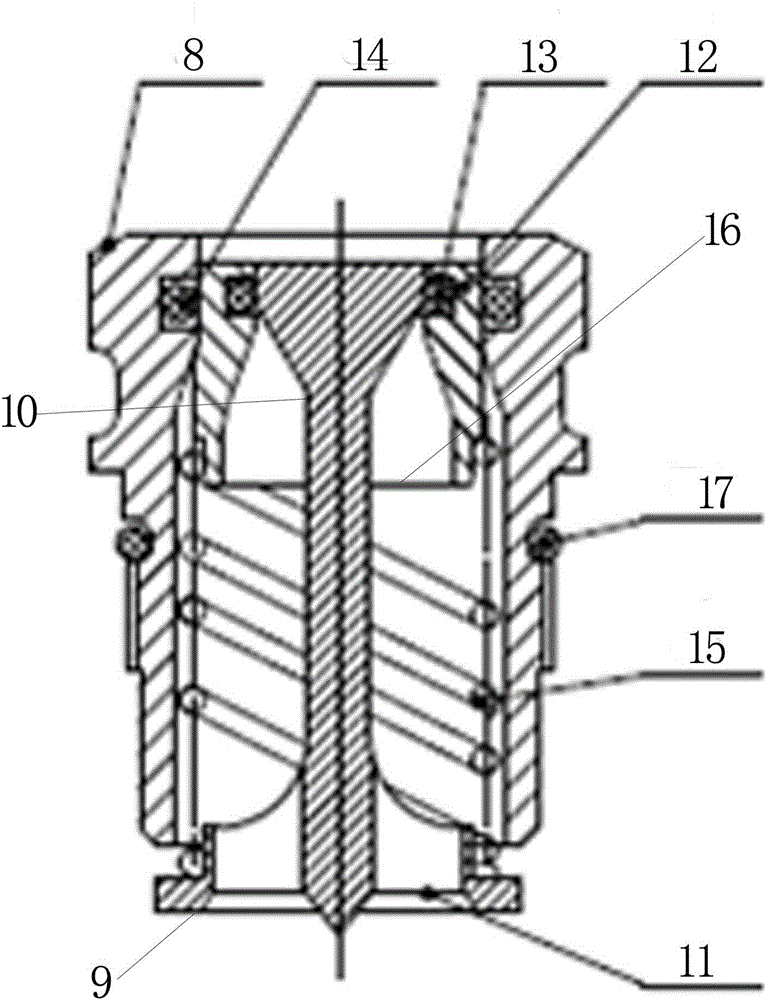

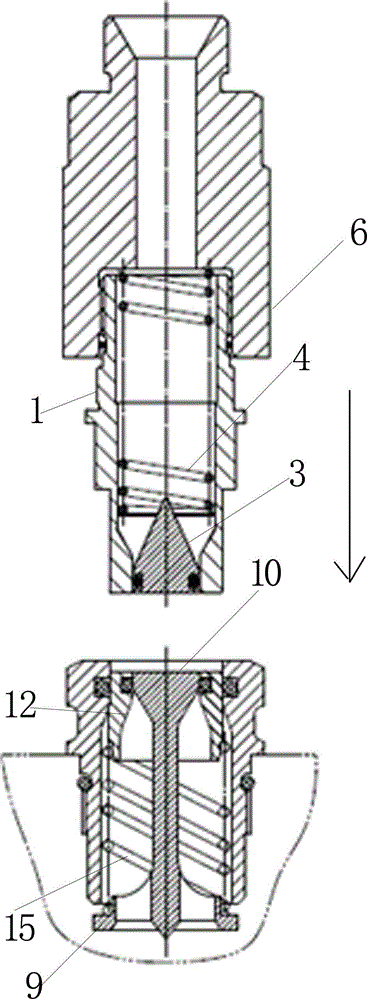

[0014] A double-closed quick connector, including a tubular male joint assembly and a female joint assembly; the male joint assembly includes a first pipe body 1 and a pipe joint 6 connected to the non-interface end of the first pipe body 1; the first Inside the pipe body 1 is provided with a first spring 4, the front end of the first spring 4 is fixedly connected with the sliding seal block 3 located in the interface end of the first pipe body 1 through the first spring catch 7, and the inner wall of the interface end of the first pipe body 1 The first sealing ring 2 matching the sliding sealing block 3 is fixed; the inner diameter of the first pipe body 1 at the rear of the sliding sealing block 3 is larger than the inner diameter of the interface end; the non-interface end of the first pipe body 1 is fixedly embedded in the front of the pipe joint 6 In the port and between the outer wall of the first pipe body 1 and the inner wall of the front port of the pipe joint 6, a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com