Electromagnetic heating device of conduction oil

An electromagnetic heating device and heat transfer oil technology, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of low heating efficiency of heat transfer oil heaters, and achieve the goal of improving heating efficiency and increasing heating area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

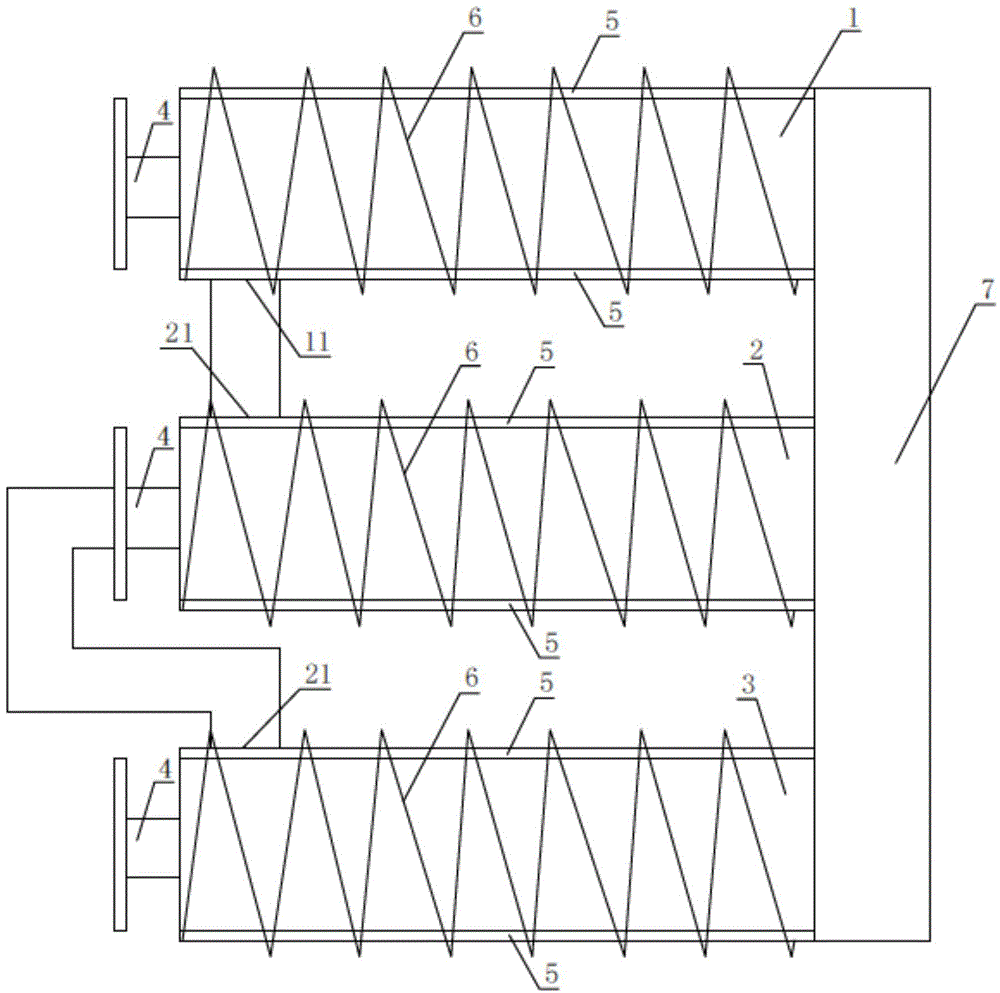

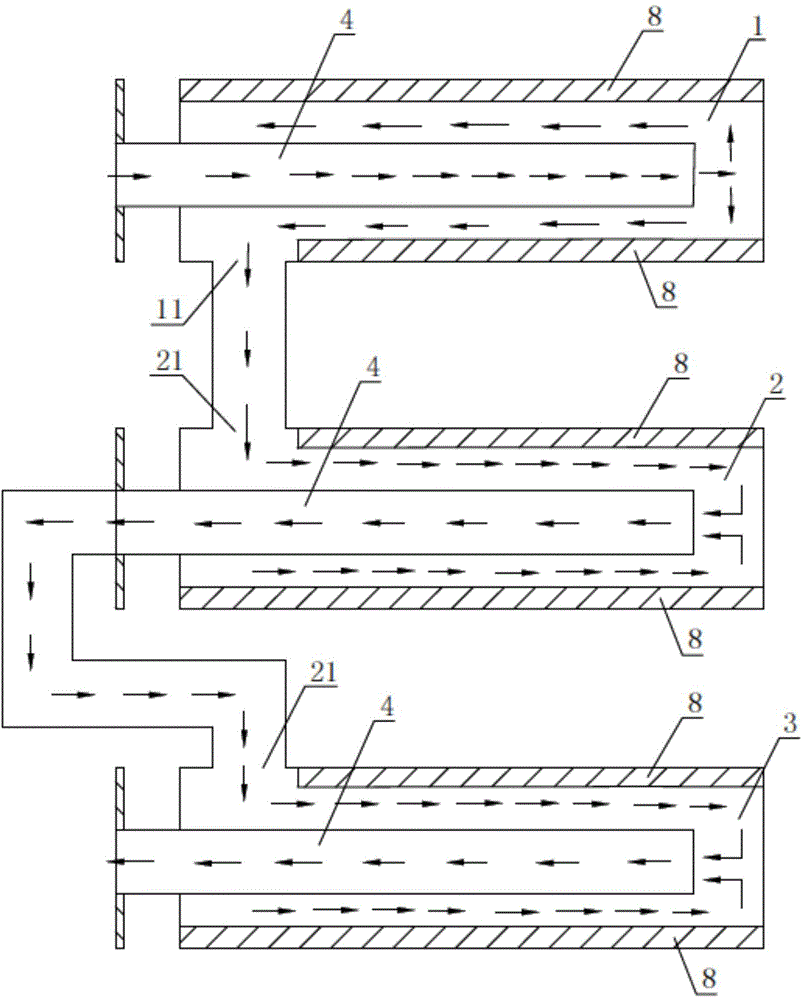

[0016] refer to figure 1 with figure 2 . An electromagnetic heating device for heat-conducting oil, comprising a heating liner 1, a heating liner 2, and a heating liner 3 that are connected in sequence and made of magnetically conductive metals, and the heating liner 1, heating liner 2, and heating liner 3 are arranged in parallel from top to bottom , The interior of the heating bladder 1, the heating bladder 2 and the heating bladder 3 is a hollow structure. The bottom of the left end of the heating tank 1 is provided with an oil outlet 11, the top of the left end of the heating tank 2 and the heating tank 3 are all provided with an oil inlet 21, and the oil outlet 11 and the oil inlet 21 of the heating tank 2 connected. The heating tank 1, the heating tank 2 and the heating tank 3 are all inserted with left and right through oil passages 4, and the left end of the oil passage 4 protrudes out of the corresponding heating tank, and the passage of the heating tank 2 The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com