Reciprocating type liquid shock absorber simulation test device

A simulation test and test device technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as insufficient analysis of causes, cumbersome adjustment process, etc., to improve the experimental environment, simplify disassembly and assembly operations, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in detail below in conjunction with accompanying drawing:

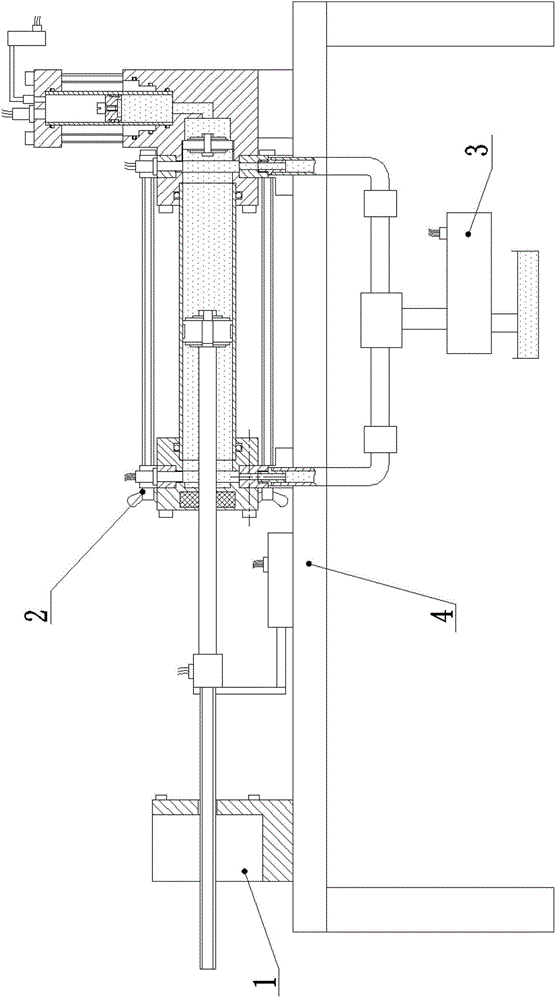

[0042] refer to figure 1 , The reciprocating liquid shock absorber simulation test device of the present invention consists of a driving device 1, a test device main body 2, an oil supply device 3 and a device installation platform 4.

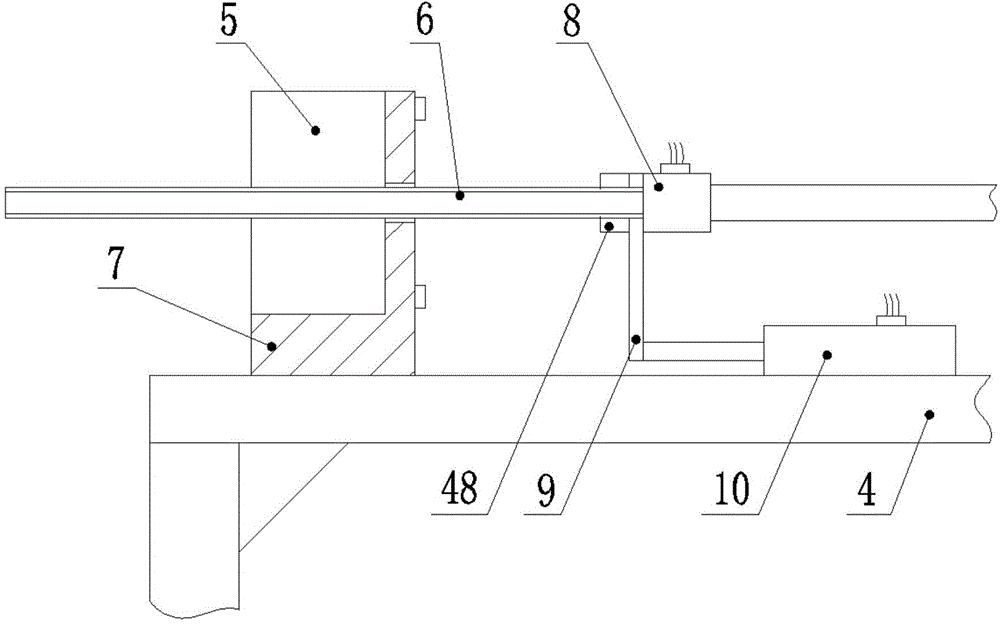

[0043] The driving device 1 is installed on the left side of the upper surface of the device installation platform 4, the main body of the test device 2 is installed on the right side of the upper surface of the device installation platform 4, and the oil supply device 3 is installed on the front beam 43 and the central beam 44 of the device installation platform 4 Lower right with rear cross member 45.

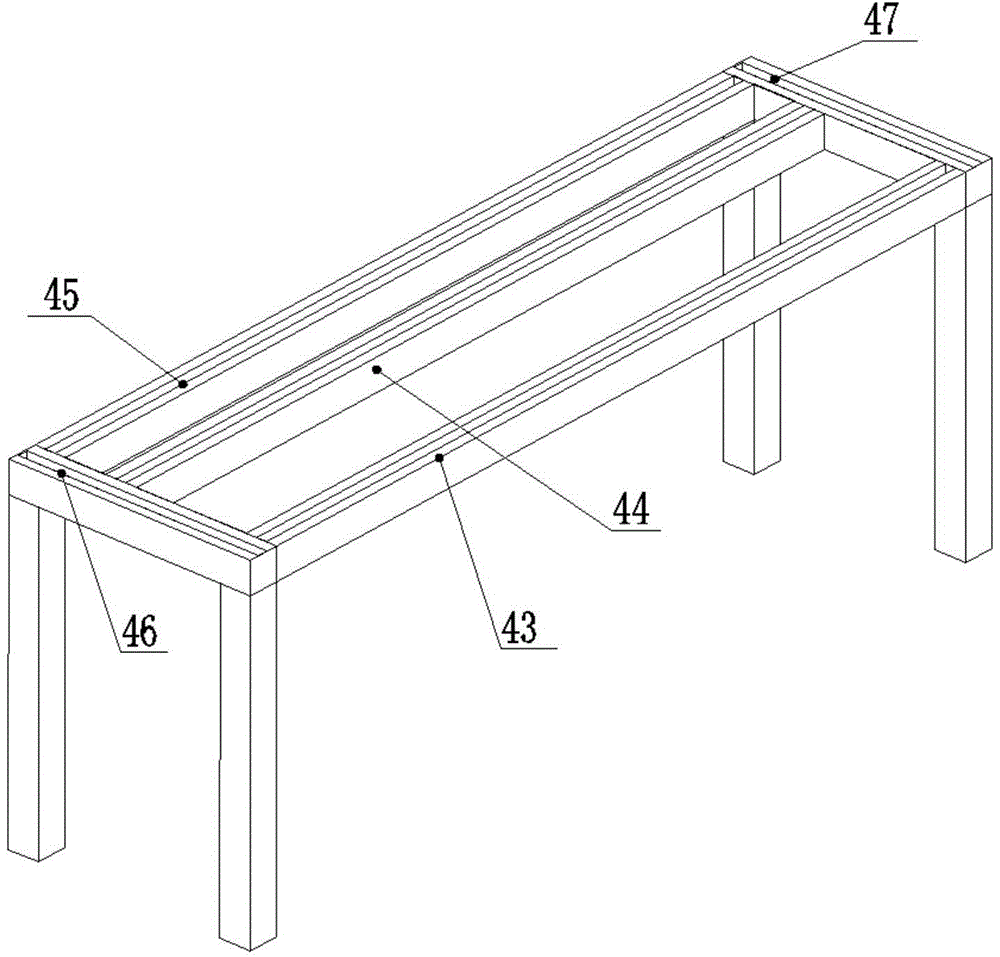

[0044] refer to figure 2 , the device installation platform 4 is a frame-type structural member built from aluminum profiles with square cross-sections and guide rail grooves. The top of the device installation platform 4 is a flat Japanes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com