Method and system for generating dendritic shrinkage porosity defect simulation image of casting

A defect and casting technology, applied in the field of automatic image generation, can solve the problems of high complexity of CAD model algorithm, low calculation cost, high cost, etc., and achieve the effect of strong diversity, high randomness and high degree of simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

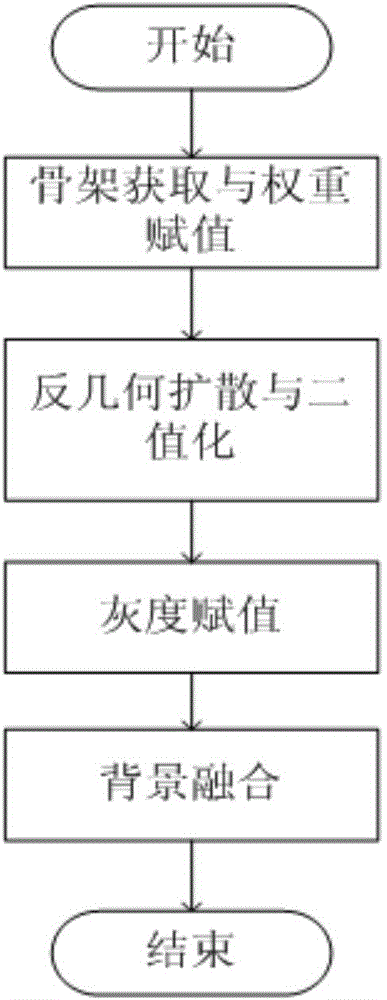

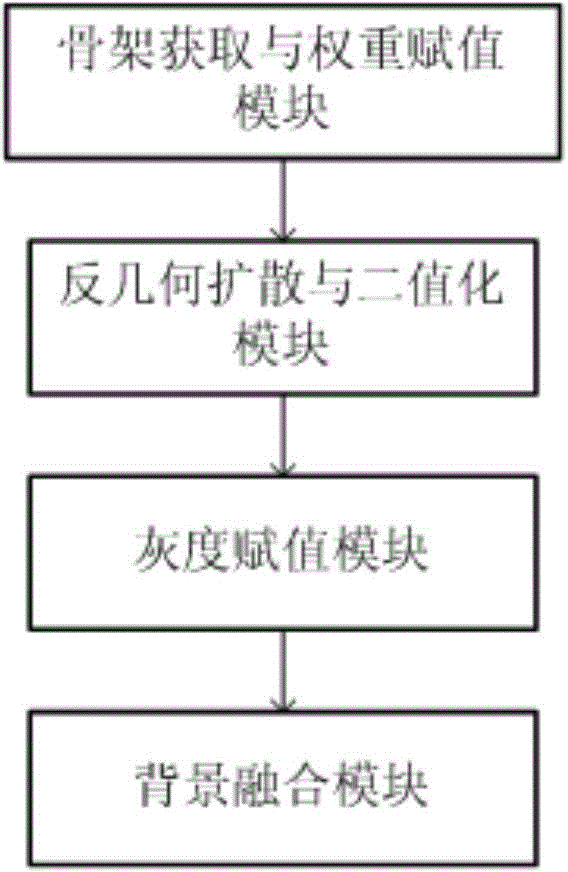

[0035] Such as figure 1 As shown, the generation method of the dendritic shrinkage defect simulation image of the casting comprises the following steps:

[0036] (1) Skeleton acquisition and weight assignment:

[0037] (1-1) Skeleton acquisition: read in the X-ray image of the casting, use a fixed threshold to binarize the defect, and obtain a three-layer template nested with each other, and count the gradient and gray information of the three-layer template respectively; then use the morphology The three-layer template is refined by a mathematical algorithm, and three skeletons representing the three-layer template are obtained; however, only the skeleton is extracted from the real defect, which limits the types of skeletons, so the operator can randomly draw the hand-painted skeleton of the required shape through matlab drawing, and expand Skeleton type.

[0038] (1-2) After obtaining the skeleton, assign weights to the points on the skeleton according to the principle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com