Resin composition, two-part laminating adhesive, laminated film, and backsheet for solar cell

A technology of resin composition and compound, applied in the direction of synthetic resin layered products, adhesives, layered products, etc., can solve the problems of weak coating film strength, deterioration of bonding strength, poor appearance, etc., and achieve strong coating film strength, adhesion The effect of high bonding strength without deterioration of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

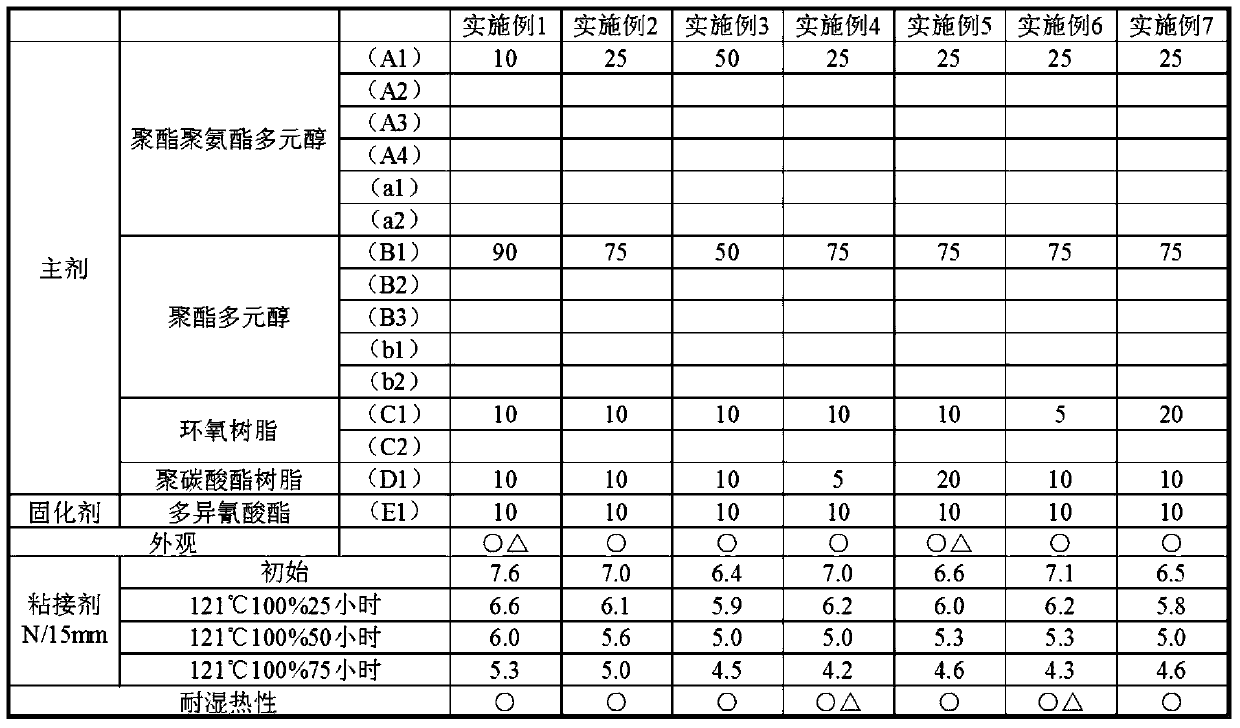

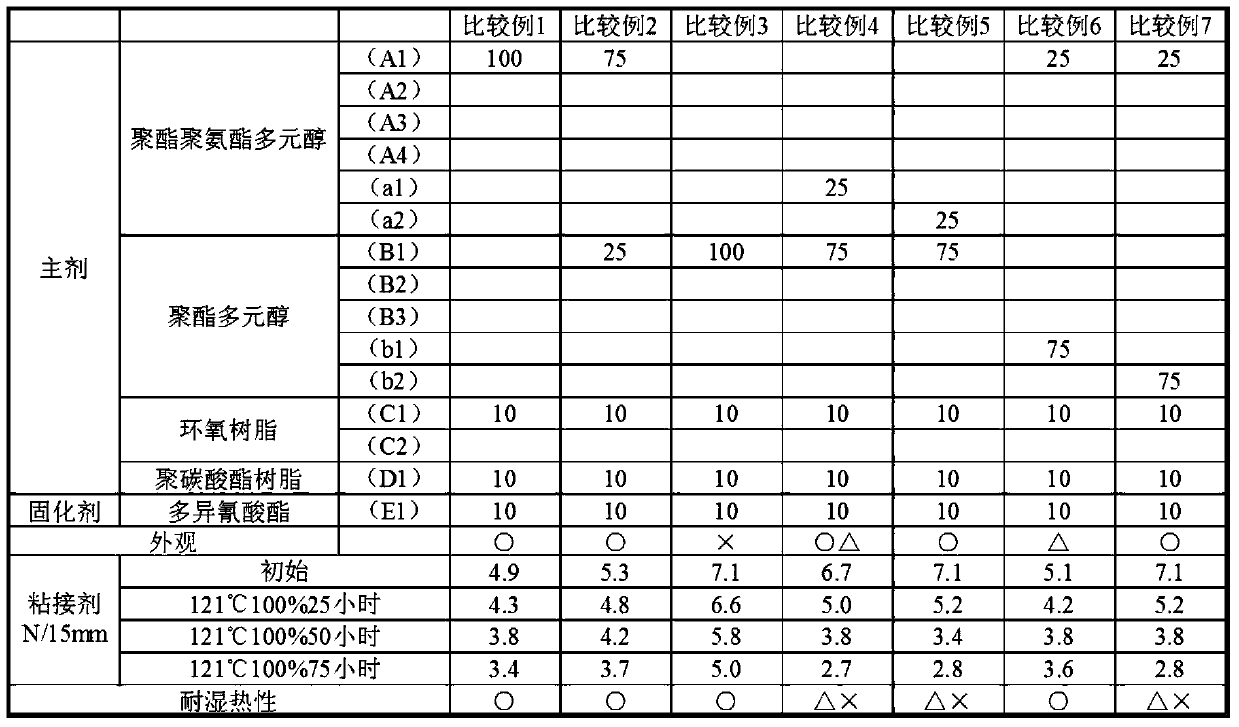

Examples

Embodiment

[0090] Hereinafter, specific synthesis examples and examples are given to describe the present invention in more detail, but the present invention is not limited to these examples. In addition, in the following examples, "parts" and "%" represent "parts by mass" and "% by mass", respectively, unless otherwise specified.

[0091] It should be noted that, in the examples of the present application, the number average molecular weight (Mn) and weight average molecular weight (Mw) were measured by gel permeation chromatography (GPC) under the following conditions.

[0092] Measuring device: HLC-8220GPC manufactured by Tosoh Corporation

[0093] Column: TSK-GUARDCOLUMN SuperHZ-L manufactured by Tosoh Corporation + TSK-GEL SuperHZM-M manufactured by Tosoh Corporation×4

[0094] Detector: RI (differential refractometer)

[0095] Data processing: Multi station GPC-8020 model II manufactured by Tosoh Corporation

[0096] Determination conditions: column temperature 40°C

[0097] ...

Synthetic example 1-1

[0101] (Synthesis Example 1-1) [Synthesis of Polyester Polyurethane Polyol (A1)]

[0102]Put 1131 parts of neopentyl glycol, 737 parts of isophthalic acid, 342 parts of phthalic anhydride, 534 parts of sebacic acid, 20 parts of trimellitic anhydride and organic titanium compound into a flask equipped with a stirring bar, a temperature sensor and a rectifying tube 1.3 parts, while passing dry nitrogen gas into the flask and stirring, it was heated to 230-250°C to carry out esterification reaction. When the acid value was 1.0 mgKOH / g or less, the reaction was stopped, and after cooling to 100° C., it was diluted with ethyl acetate until the solid content was 80%. Next, 124 parts of hexamethylene diisocyanate modified isocyanurate (SUMIDUR N-3300; manufactured by Sumitomo Bayer Urethane Co., Ltd.) and 25 parts of hexamethylene diisocyanate were put into the flask. Pass through dry nitrogen and stir, while heating to 70-80°C to carry out urethanization reaction. The reaction was...

Synthetic example 1-2

[0103] (Synthesis Example 1-2) [Synthesis of Polyester Polyurethane Polyol (A2)]

[0104] Put 1155 parts of neopentyl glycol, 755 parts of isophthalic acid, 325 parts of phthalic anhydride, 507 parts of sebacic acid, 20 parts of trimellitic anhydride and organic titanium compound into the flask with stirring rod, temperature sensor and rectification tube 1.3 parts, while passing dry nitrogen gas into the flask and stirring, it was heated to 230-250°C to carry out esterification reaction. When the acid value was 1.0 mgKOH / g or less, the reaction was stopped, and after cooling to 100° C., it was diluted with ethyl acetate until the solid content was 80%. Next, 247 parts of an isocyanurate-modified body of hexamethylene diisocyanate (SUMIDUR N-3300; manufactured by Sumitomo Bayer Urethane Co., Ltd.) and 40 parts of hexamethylene diisocyanate were put into the flask. Pass through dry nitrogen and stir, while heating to 70-80°C to carry out urethanization reaction. The reaction w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com